Rokee is a chinese Crown Pin Couplings Manufacturer, provide Crown Pin Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Crown Pin Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Crown Pin Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

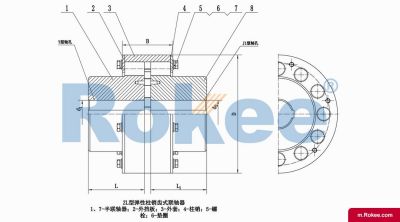

LZ/ZL Elastic Pin Gear Coupling

LZ Pin Gear Coupling is the basic form of this series of couplings.View More -

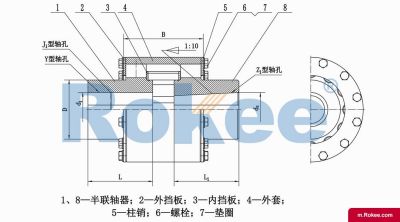

LZD/ZLD Elastic Pin Gear Coupling With Conical Shaft Hole

One end of the LZD Pin Gear Coupling is designed with a conical shaft hole, and the clearance between the semi-couplings is increased to facilitate the fixing space at the shaft end.View More -

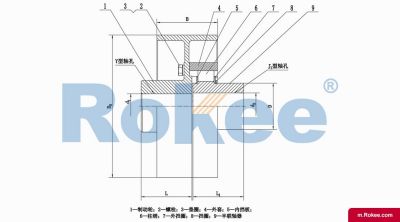

LZZ/ZLL Elastic Pin Gear Coupling With Brake Wheel

LZZ Pin Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View More

Crown Pin Coupling is a common mechanical transmission component, mainly used to connect two shafts and transmit torque. Crown Pin Coupling is a device that uses column pins to connect two halves of the coupling. According to the different materials of column pins, Crown Pin Couplings are mainly divided into the following categories:

Elastic sleeve Pin Coupling: One end of the column pin is fitted with an elastic sleeve (rubber material), which is installed in the flange holes of the two halves of the coupling to achieve the connection of the two halves of the coupling.

Cylindrical pin coupling: A cylindrical metal material column pin is placed in the flange hole of the half coupling, and the two halves of the coupling are connected through the cylindrical pin.

Elastic Pin Coupling: A column pin made of several non-metallic elastic materials (such as nylon) is placed in the flange holes of the two halves of the coupling, and the two halves of the coupling are connected through the column pin.

Characteristics and advantages

Simple structure: The structure of the Crown Pin Coupling is relatively simple, easy to manufacture and install.

No lubrication required: The pin coupling does not require lubrication during operation, reducing maintenance costs.

Compensation capability: It has a certain ability to compensate for the relative offset of two axes, and is suitable for situations where the axes are not centered within a certain range.

Buffer and shock absorption: Elastic sleeves or elastic pins have a certain degree of elasticity, which can play a role in buffering and shock absorption.

Application and Limitations

Application scope: Crown Pin Couplings are widely used in various mechanical transmission systems, such as ships, automobiles, machine tools, etc.

Restriction: The elastic pin coupling is not suitable for working conditions with high reliability requirements, such as the transmission shaft system of the lifting mechanism of lifting machinery. At the same time, for working conditions with large radial and angular offsets, as well as transmission shaft systems with low installation accuracy, it is not advisable to use elastic pin couplings.

Selection and Installation

Selection: When choosing a Crown Pin Coupling, factors such as the size of the transmitted torque, axis offset, and working environment need to be considered. Ensure that the selected coupling meets the usage requirements.

Installation: When installing the Crown Pin Coupling, it should be ensured that the axis of the two halves of the coupling is well aligned to avoid excessive axis deviation that may cause damage to the coupling. At the same time, the coupling should be regularly inspected and maintained to ensure its normal operation.

Maintenance

Regular inspection: Regularly check the wear of the coupling and replace severely worn components in a timely manner.

Cleaning and lubrication: Although the pin coupling does not require lubrication, it should be kept clean to prevent debris from entering the coupling and affecting its operation.

Attention to alignment: During installation and use, it is important to keep the axis of the two halves of the coupling aligned to avoid excessive axis deviation that may damage the coupling.

In the complex ecosystem of mechanical transmission systems, couplings serve as the critical link that bridges driving and driven shafts, ensuring the smooth transfer of torque while accommodating inevitable misalignments and mitigating operational shocks. Among the diverse range of coupling types available, the crown pin coupling stands out as a versatile and robust solution, widely embraced in numerous industrial applications for its straightforward design, ease of use, and cost-effectiveness. Unlike more intricate transmission components that demand sophisticated manufacturing processes or frequent maintenance, the crown pin coupling embodies the principle of functional simplicity, making it an indispensable element in low-to-medium speed and torque environments.

At the heart of the crown pin coupling’s functionality lies its uncomplicated yet efficient structural design. Typically, this type of coupling consists of three primary components: two semi-couplings, a set of non-metallic flexible pins, and in some configurations, a toothed sleeve ring with an outer ring. The semi-couplings are engineered with flange holes that correspond to the size and number of the flexible pins, allowing for a secure connection between the two halves. Each semi-coupling is designed to be mounted on the end of a respective shaft—one connected to the driving power source, such as an electric motor or internal combustion engine, and the other to the driven equipment, like a pump, fan, or conveyor. The non-metallic flexible pins, often made from materials such as rubber, urethane, or other resilient polymers, are inserted through the flange holes of both semi-couplings, forming the key torque-transmitting interface. This non-metallic construction is a defining feature of the crown pin coupling, as it imparts the necessary flexibility to absorb shocks and compensate for misalignments without the need for lubrication, a significant advantage over metal-on-metal coupling designs.

The working principle of the crown pin coupling revolves around the synergistic interaction of its components to achieve efficient torque transmission while accommodating various forms of misalignment. When the driving shaft rotates, it imparts rotational force to the attached semi-coupling. This force is then transferred through the non-metallic flexible pins to the second semi-coupling, which in turn drives the driven shaft. The flexible nature of the non-metallic pins allows them to deform slightly under load, enabling the coupling to absorb shock and vibration generated during operation. This shock absorption capability is crucial in reducing stress on both the shafts and the connected equipment, thereby extending their operational lifespan. Additionally, the flexibility of the pins enables the coupling to compensate for three common types of misalignment: angular misalignment, where the axes of the two shafts are inclined relative to each other; parallel offset, where the shafts are parallel but laterally displaced; and axial misalignment, or end float, which refers to the relative axial displacement of the connected shafts. By accommodating these misalignments, the crown pin coupling ensures smooth and uninterrupted power transmission even when perfect alignment between shafts is difficult to achieve due to manufacturing tolerances, installation errors, or thermal expansion and contraction during operation.

One of the most notable advantages of the crown pin coupling is its wide range of applications across various industrial sectors, driven by its adaptability to diverse operating conditions and its cost-effective performance. Its suitability for low-to-medium speed and low-to-medium torque applications makes it a preferred choice in many general industrial settings. For instance, in material handling systems, crown pin couplings are commonly used in conveyors, where they ensure the reliable transfer of power from electric motors to the conveyor belts, even in the presence of minor misalignments caused by the long span of the conveyor structure. In the lifting and hoisting industry, cranes—including seaport cargo cranes that operate in harsh, high-load environments—rely on crown pin couplings to connect their drive systems to the lifting mechanisms. The coupling’s shock absorption capability is particularly valuable here, as it helps to mitigate the impact loads generated when lifting and lowering heavy cargo, enhancing operational safety and reducing wear on critical components.

Beyond material handling and lifting equipment, crown pin couplings find applications in a variety of other industrial machinery. Fans and blowers, which are essential for ventilation and air circulation in factories, warehouses, and commercial buildings, often utilize these couplings due to their simple maintenance requirements and ability to handle the moderate torque demands of such equipment. Pumps, including chemical pumps that operate in corrosive environments, also benefit from the crown pin coupling’s design; the non-metallic pins can be selected from corrosion-resistant materials to ensure long-term performance in harsh chemical conditions. amusement equipment, such as amusement park rides, represent another unique application area, where the coupling’s reliability and ability to absorb sudden shocks are critical for ensuring the safety of passengers. Additionally, the coupling is used in screening machines, washing equipment, and various other general industrial machinery, further demonstrating its versatility.

The widespread adoption of crown pin couplings is also attributed to a set of inherent advantages that make them a practical choice for many industrial applications. First and foremost, their simple structure facilitates easy manufacturing, which translates to lower production costs and, consequently, more affordable pricing for end-users. This cost-effectiveness is particularly appealing for small and medium-sized enterprises that need reliable transmission components without incurring excessive expenses. Secondly, the absence of a requirement for lubrication simplifies operational maintenance, reducing both the time and cost associated with regular upkeep. Unlike lubricated couplings that require periodic oil changes or grease replenishment, crown pin couplings can operate for extended periods without additional maintenance, minimizing downtime and improving overall operational efficiency.

Another key advantage is the ease of assembly and disassembly. The design of the crown pin coupling allows for quick and straightforward installation, even in tight spaces, as the semi-couplings can be mounted on the shafts independently before being connected by the flexible pins. Similarly, when maintenance or replacement is necessary, the flexible pins can be easily removed and replaced without the need for specialized tools or complex procedures. This ease of maintenance is crucial in industrial environments where downtime can result in significant productivity losses. Additionally, the non-metallic flexible pins are typically lightweight and readily available, making replacement parts easy to source and install. Furthermore, the crown pin coupling exhibits good torsional flexibility, which enables it to dampen impulsive loads and vibrations, protecting the connected shafts and equipment from premature failure. This torsional flexibility is particularly beneficial in applications where the driving power source generates intermittent or variable loads, such as in machinery powered by single-cylinder internal combustion engines.

When selecting a crown pin coupling for a specific application, several key factors must be carefully considered to ensure optimal performance and reliability. The first and most critical factor is the torque requirement. The coupling must be capable of transmitting the maximum torque generated by the driving power source without exceeding its rated torque capacity. To determine the appropriate coupling size, it is necessary to calculate the selection power, which takes into account not only the nominal power of the driving motor but also service factors that account for the operating conditions. Service factors are influenced by variables such as the type of driving power source (e.g., electric motor, multi-cylinder engine, single-cylinder engine), the duration of daily operation, and the nature of the load (steady, medium impulsive, highly impulsive). For example, a coupling used with a single-cylinder internal combustion engine that operates for more than 10 hours per day and handles highly impulsive loads will require a higher service factor than one used with an electric motor operating under steady load conditions for a shorter duration.

Another important consideration is the misalignment tolerance. The selected coupling must be able to accommodate the expected types and degrees of misalignment between the driving and driven shafts. Crown pin couplings typically have specific limits for angular, parallel, and axial misalignment, and exceeding these limits can lead to premature wear of the flexible pins, increased vibration, and reduced coupling lifespan. It is therefore essential to assess the potential misalignment in the application, which may result from factors such as shaft deflection under load, thermal expansion, or installation errors, and select a coupling that can handle these misalignments comfortably.

Environmental conditions also play a significant role in the selection process. Couplings operating in harsh environments, such as those exposed to high temperatures, corrosive chemicals, moisture, or dust, require materials that can withstand these conditions. For example, in high-temperature applications, the non-metallic flexible pins should be made from heat-resistant materials to prevent degradation, while in corrosive environments, the semi-couplings may need to be constructed from corrosion-resistant metals or coated with protective finishes. Additionally, the operating speed must be considered, as crown pin couplings have maximum speed limits that should not be exceeded to avoid excessive centrifugal forces, which can damage the components.

Size and space constraints are also practical factors to consider. The coupling must fit within the available space in the machinery, and its dimensions must be compatible with the shaft diameters of the driving and driven equipment. It is important to verify that the coupling’s hub diameter and length do not interfere with other components in the system, and that the bore size of the semi-couplings matches the shaft diameters. Finally, maintenance needs should be taken into account, with preference given to couplings that allow for easy access to the flexible pins for replacement, minimizing downtime in case of component failure.

Proper installation is crucial to ensuring the optimal performance and longevity of crown pin couplings. The installation process typically begins with the preparation of the shafts, which should be clean, free of burrs, and have the correct surface finish to ensure a secure fit with the semi-couplings. The semi-couplings are then mounted on the respective shafts, using keys or set screws to lock them in place. It is essential to ensure that the semi-couplings are installed flush against the shaft shoulders to prevent axial movement during operation. Once the semi-couplings are in place, the next step is to align the shafts as accurately as possible. While crown pin couplings can accommodate minor misalignments, proper initial alignment reduces stress on the flexible pins and extends their lifespan. Alignment can be checked using simple tools such as a straight rule for preliminary checks or a dial gauge for more precise measurements. The goal is to minimize both angular and parallel misalignment to within the coupling’s specified limits.

After alignment is confirmed, the non-metallic flexible pins are inserted through the flange holes of both semi-couplings. Care should be taken to ensure that the pins are properly seated and that there is no binding or excessive tightness, which could restrict their flexibility. In some configurations, retaining rings or washers may be used to secure the pins in place, preventing them from dislodging during operation. Once the pins are installed, a final check of the alignment and coupling assembly should be performed to ensure that all components are properly positioned and secured. It is also advisable to run the machinery at a reduced speed initially to check for any unusual vibrations or noises, which could indicate misalignment or improper installation.

Although crown pin couplings require minimal maintenance, regular inspection and timely replacement of worn components are essential to prevent unexpected failures and ensure continuous operation. Routine maintenance typically involves periodic visual inspections of the coupling components to check for signs of wear, damage, or degradation. The non-metallic flexible pins are the most susceptible to wear and should be inspected regularly for cracks, tears, hardening, or excessive deformation. If any of these signs are present, the pins should be replaced immediately to avoid loss of flexibility, increased vibration, and potential damage to the semi-couplings or shafts.

In addition to inspecting the flexible pins, the semi-couplings should be checked for signs of wear, corrosion, or damage to the flange holes. Worn or elongated flange holes can cause excessive play between the pins and the semi-couplings, leading to increased vibration and reduced torque transmission efficiency. If such wear is detected, the semi-couplings may need to be repaired or replaced. The mounting hardware, such as keys, set screws, and retaining rings, should also be inspected to ensure that they are secure and not loose, as loose hardware can lead to axial or radial movement of the semi-couplings, resulting in misalignment and premature wear.

The frequency of maintenance inspections depends on the operating conditions of the coupling. Couplings operating in harsh environments, under heavy loads, or for extended periods may require more frequent inspections—possibly on a weekly or monthly basis. Those operating under milder conditions may only need to be inspected quarterly or annually. It is also advisable to keep a record of maintenance activities, including the date of inspection, any issues identified, and the components replaced, to track the performance and lifespan of the coupling over time.

In conclusion, the crown pin coupling is a fundamental component in mechanical transmission systems, offering a reliable, cost-effective, and low-maintenance solution for torque transmission in a wide range of industrial applications. Its simple yet efficient design, characterized by two semi-couplings and non-metallic flexible pins, enables it to absorb shocks, compensate for misalignments, and operate without lubrication, making it ideal for low-to-medium speed and torque environments. From material handling conveyors and seaport cranes to fans, pumps, and amusement equipment, the crown pin coupling plays a vital role in ensuring the smooth and efficient operation of numerous industrial machinery.

The successful application of crown pin couplings depends on careful selection based on torque requirements, misalignment tolerance, environmental conditions, and size constraints, as well as proper installation and routine maintenance. By adhering to these principles, industrial operators can maximize the performance and lifespan of crown pin couplings, minimizing downtime and reducing operational costs. As industrial technology continues to evolve, the crown pin coupling is likely to remain a staple in mechanical transmission systems, thanks to its inherent advantages and adaptability to changing industrial needs. Its enduring popularity is a testament to the value of functional simplicity in engineering, proving that sometimes the most effective solutions are the ones that prioritize reliability and ease of use above complex design.

« Crown Pin Couplings » Update Date: 2026/1/10

URL: https://m.rokee.com/tags/crown-pin-couplings.html