Rokee is a chinese Plate Couplings Manufacturer, provide Plate Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Plate Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Plate Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

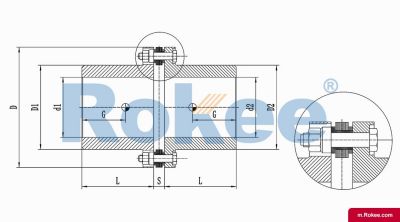

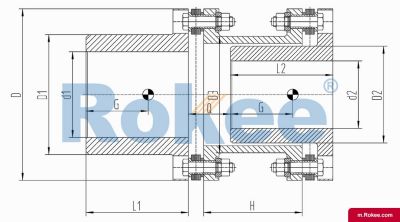

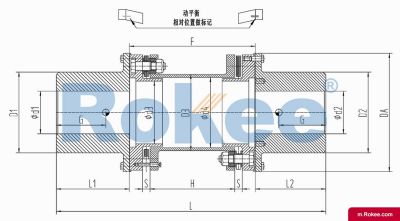

RLM Standard Single Section Small Metal Diaphragm Coupling

The RLM standard single section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working situations with a working speed not exceeding 5000rpm, and cannot compensate for radial errors.View More -

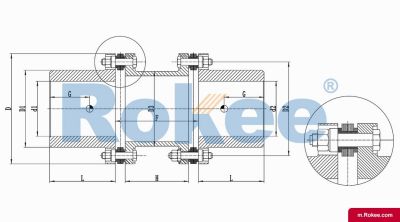

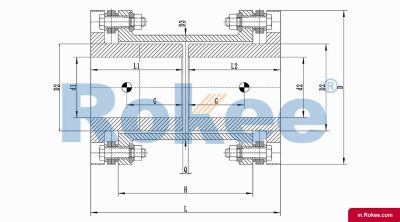

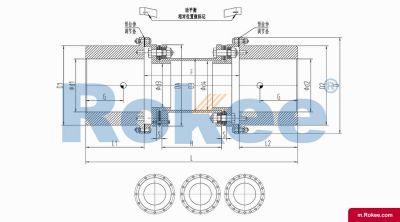

RLMD Standard Double Section Small Metal Diaphragm Coupling

The RLMD standard double section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working occasions with a working speed not exceeding 5000rpm.View More -

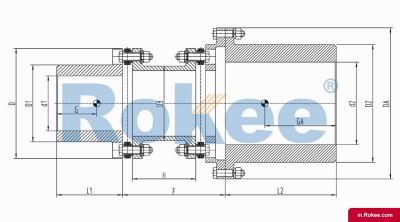

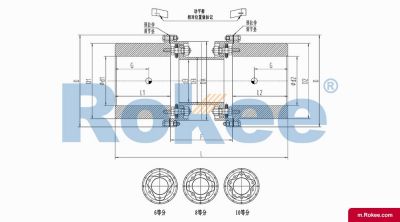

RLA Standard Single Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings,reliable choice for medium to low speed applications,but it cannot compensate for radial deviation.View More -

RLAD Standard Double Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications.View More -

RLAR Single Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

Single side shaft sleeve reverse installation design, suitable for occasions with limited shaft head distance.View More -

RLARD Double Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

The double-sided shaft sleeve reverse installation design is also applicable in situations where the distance from the shaft head is limited or the additional bending moment is smaller.View More -

RLAF Large & Small Shaft Mounted Metal Diaphragm Coupling

The size difference design of the bilateral shaft sleeve is suitable for situations where the diameter difference between the two ends of the shaft is significant.View More -

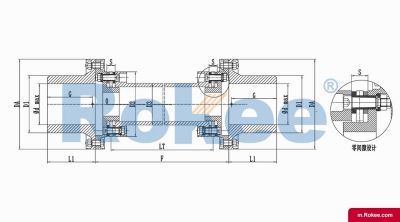

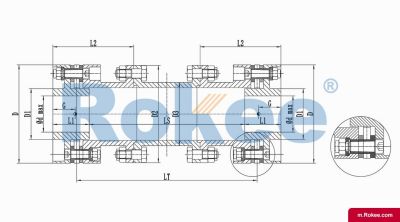

RLAT Super Long Wheelbase Metal Diaphragm Coupling

Adopting an intermediate shaft design, suitable for ultra long shaft spacing power transmission applications.View More -

RLQA No Flange Quick Installation Metal Diaphragm Coupling

Suitable for various industrial process pumps, fans, and other medium to low speed applications, with a maximum speed generally not exceeding 25000 rpm. It meets the requirements of API610/ISO14691 and is one of the first products for API applications.View More -

RLQF Flange Type Quick Installation Metal Diaphragm Coupling

Suitable for drum pressure fans, turbine compressors, and other high speed applications, with a maximum speed of up to 35000rpm.View More -

RLQU Improved Flange Quick Installation Metal Diaphragm Coupling

The improved RLQF has smaller additional bending moments and better performance. Suitable for drum pressure fans, turbine compressors, and other high speed applications.View More -

RLHD High Speed Metal Diaphragm Coupling

Suitable for higher speed applications, it also adopts a flexible component integrated assembly design, with a maximum speed of up to 42000rpm.View More -

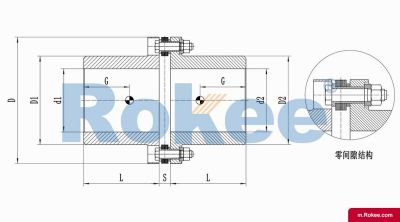

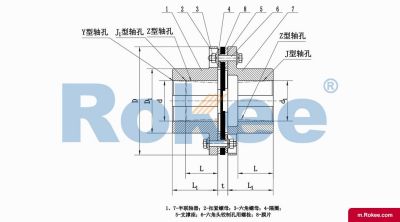

JMI Single Diaphragm Coupling With Counterbore

JMI metal diaphragm coupling adopts the single-piece design, suitable for short distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

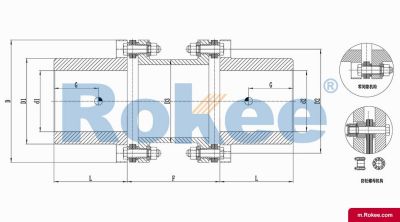

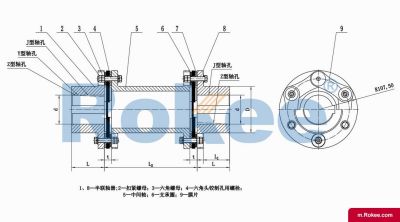

JMIJ Double Diaphragm Coupling With Intermediate Shaft

JMIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

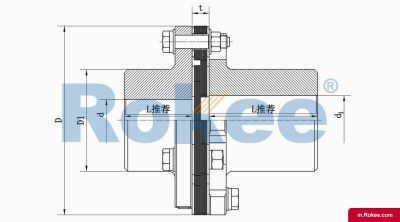

JMII Single Diaphragm Coupling Without Counterbore

JMII metal diaphragm coupling also adopts the single-piece design but has no counterbore, suitable for short distance transmission, with more compact structure.View More -

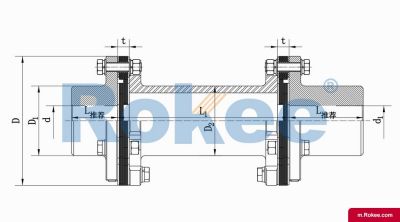

JMIIJ Double Diaphragm Coupling With Intermediate Shaft

JMIIJ Diaphragm Coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at both ends have no counterbore.View More

Plate Couplings belong to a type of metal flexible couplings, mainly composed of high-strength alloy steel sheets as elastic elements, connected to the half couplings at both ends through bolts. This type of coupling compensates for various deviations between shaft systems through the elastic deformation of steel plates, while transmitting torque and rotational motion. Compared with traditional couplings, Plate Couplings have significant advantages such as compact structure, high torque transmission, and no maintenance required.

Plate Couplings can be divided into two categories based on their structural form: single diaphragm type and double diaphragm type. The single membrane structure is simple and mainly compensates for angular and radial deviations; The double diaphragm type has stronger deviation compensation capability and can simultaneously compensate for axial, radial, and angular deviations, making it more widely used. In addition, according to the arrangement of steel plates, they can be divided into different types such as parallel steel plate groups and staggered steel plate groups, which are suitable for different torque and speed requirements.

The core structure of the steel plate coupling consists of three main parts: two flanged half couplings, a set of high-strength alloy steel plates (diaphragm group), and connecting bolts. Half couplings are usually made of high-quality alloy steel, with one end connected to the drive shaft and the driven shaft through keyway or clamping, and the other end equipped with a flange for connecting the steel plate group. The steel sheet group is composed of multiple ultra-thin high-strength stainless steel sheets stacked together, which have undergone special heat treatment processes and have extremely high fatigue strength and elasticity. The connecting bolts are made of high-strength alloy steel and undergo precision machining and quenching treatment to ensure reliability under high-speed rotation.

The working principle of steel plate couplings is based on the principle of metal elastic deformation. When the driving shaft rotates, the torque is transmitted to the steel plate group through the half coupling, and then transmitted to the other half coupling by the steel plate group, ultimately driving the driven shaft to rotate. During this process, if there are axial, radial, or angular deviations between the two shafts, the steel plate assembly will undergo corresponding elastic deformation to absorb these deviations, thereby avoiding additional stress on the shaft and bearings. The special arrangement of steel plates enables them to flexibly adapt to various deviation situations while withstanding torque.

Taking the double diaphragm steel plate coupling as an example, its torque transmission path is: drive shaft → drive end half coupling → drive end steel plate group → intermediate shaft → driven end steel plate group → driven end half coupling → driven shaft. This structural design enables the coupling to effectively compensate for larger shaft system deviations through the coordinated deformation of two sets of steel plates. Meanwhile, the length of the intermediate shaft can be adjusted according to actual needs, providing greater flexibility for system design.

Plate Couplings have multiple outstanding performance characteristics, making them widely used in many industrial fields. One of its most prominent features is the maintenance free design. As there are no relatively sliding parts inside the coupling, all transmission components are rigidly connected by metal, so there is no need to add lubricating oil or grease. This feature not only reduces maintenance costs, but also avoids the problem of lubricant pollution to the environment, making it particularly suitable for industries with high cleanliness requirements such as food and medicine.

High torque transmission capability is another major advantage of steel plate couplings. Compared with other types of couplings of the same size, steel plate couplings can transmit greater torque. This is mainly due to the adoption of high-strength alloy steel sheets and optimized structural design. For example, by designing a staggered arrangement of fan-shaped steel plates, the torque capacity can be significantly increased without increasing the radial size of the coupling. In addition, the steel plate coupling has high torsional stiffness and good transmission accuracy, which can meet the demanding requirements of precision transmission systems.

In terms of deviation compensation capability, steel plate couplings perform well. A typical steel plate coupling can compensate for axial deviation up to ± 0.5mm, radial deviation up to ± 0.3mm, and angular deviation up to ± 0.5 °. The design of the dual membrane structure further enhances these compensation capabilities, enabling it to adapt to more complex shaft alignment situations. It is worth noting that steel plate couplings do not generate reverse forces when compensating for deviations, which means they do not transmit additional loads to adjacent bearings, thereby extending the service life of the bearings.

Plate Couplings also have good environmental adaptability. The all metal structure enables it to operate stably within the extreme temperature range of -80 ° C to+300 ° C, and is not affected by environmental factors such as oil stains and dust. In addition, steel plate couplings also have corrosion resistance, and some models are made of stainless steel materials, which can be suitable for corrosive environments such as marine environments or chemical industries. In terms of high-speed performance, the steel plate coupling that has undergone precision dynamic balancing can reach a maximum speed of over 30000 rpm, meeting the needs of high-speed applications such as turbomachinery.

Plate Couplings have been widely used in many industrial fields due to their excellent performance. In the field of turbomachinery, including centrifugal compressors, steam turbines, gas turbines and other equipment, steel plate couplings are the preferred transmission components. These devices usually operate at high speeds (above 3000rpm) and have extremely demanding vibration requirements. The high-speed capability and good vibration reduction characteristics of steel plate couplings perfectly meet the requirements. For example, in large centrifugal compressors, steel plate couplings are used to connect the motor and compressor spindle, which can compensate for shaft deviation caused by thermal expansion and transmit up to millions of Newton meters of torque.

Ship propulsion system is another important application area of Plate Couplings. In the transmission system between the diesel engine and propeller shaft of a ship, the steel plate coupling can effectively absorb the torsional vibration of the diesel engine, compensate for the shaft system deviation caused by the deformation of the hull, and withstand huge propulsion torque. Compared with traditional gear couplings, steel plate couplings have a simpler structure, lighter weight, and do not require lubrication systems, greatly improving the reliability of the transmission system and reducing maintenance workload. Especially on military vessels, the application of steel couplings can reduce transmission noise and improve the concealment of the vessel.

In industrial pump applications, steel plate couplings exhibit unique advantages. Large centrifugal pumps in the petrochemical industry often need to handle high-temperature media, resulting in significant thermal expansion differences between the pump shaft and the motor shaft. The steel plate coupling can not only adapt to this thermal displacement, but also withstand the high temperature radiation of the pumped medium. In addition, in shielded pumps and magnetic pumps that require absolute prevention of medium leakage, the fully enclosed structure of the steel plate coupling completely eliminates the possibility of lubricant contamination of the medium, ensuring the purity of the process flow.

Plate Couplings are also widely used in the field of power generation equipment. Whether it is traditional thermal power generation units or emerging wind power equipment, Plate Couplings play a crucial role. In wind turbines, the coupling connecting the gearbox and the generator needs to withstand extreme load changes and frequent start stop impacts. The high fatigue life and overload protection characteristics of steel plate couplings make them an ideal choice. Some advanced designs also combine steel plate couplings with damping elements, further improving the stability of the transmission system under sudden load changes.

The connection between high-speed machine tool spindles and drive motors is increasingly using steel plate couplings. The spindle of the machine tool has extremely high requirements for transmission accuracy and dynamic response. The zero backlash characteristic of the steel plate coupling ensures machining accuracy, while its high torsional stiffness ensures good dynamic response. Compared with traditional elastic couplings, Plate Couplings can more accurately transmit the motion of the motor to the spindle, avoiding contour errors caused by elastic deformation of the coupling. This is particularly important for high-precision mold processing and micrometer level precision part processing.

Axis deviation assessment is another key factor in selection. In practical applications, a completely ideal shaft alignment is almost non-existent, so it is necessary to choose the appropriate coupling model based on the estimated axial, radial, and angular deviations. Generally speaking, double diaphragm steel plate couplings have better deviation compensation capabilities than single diaphragm couplings. It is worth noting that the deviation compensation capability of the coupling will decrease with increasing speed, so special attention should be paid to this in high-speed applications. Experience has shown that controlling the actual deviation within 50% of the rated compensation capacity of the coupling can significantly extend the service life of the coupling.

Environmental factors should also be fully considered when selecting. For high-temperature environments, couplings made of heat-resistant stainless steel materials should be selected; For corrosive environments, it is necessary to choose models with corrosion-resistant coatings; In areas with explosion hazards, it may be necessary to use couplings with explosion-proof design. In addition, space constraints are also factors to consider when selecting, and the compact design of steel plate couplings is particularly suitable for installation situations with limited space.

The correct installation method is crucial for the performance of steel plate couplings. Before installation, the alignment of the shaft should be carefully checked, and precision tools such as laser alignment instruments should be used as much as possible to minimize deviations. During installation, the bolts should be tightened according to the torque values provided by the manufacturer to avoid being too tight or too loose. For large couplings that require on-site dynamic balancing, professional personnel should perform balancing calibration. After installation, manual turning should be performed to check for any interference or abnormal sounds, and only after confirming that there are no errors, can a trial run be carried out.

Although steel couplings are designed for maintenance free, regular inspections are still necessary for maintenance and monitoring. It is recommended to check the alignment status of the coupling, bolt tightening, and whether there are cracks or deformations in the steel plate every 3-6 months. For critical equipment, a vibration monitoring system can be used to monitor the operating status of the coupling in real time, and potential faults can be detected early through vibration spectrum analysis. When fatigue cracks or permanent deformation are found in the steel plate, it should be replaced in a timely manner to avoid sudden failure of the coupling causing greater equipment damage.

Plate Couplings have a unique position in the coupling family, with their own advantages and disadvantages compared to other types of couplings. Compared with gear couplings, the biggest advantage of steel plate couplings is their maintenance free design. Although gear couplings can transmit greater torque, they require regular lubrication, and poor lubrication can easily lead to tooth wear. And the steel plate coupling does not require lubrication at all, avoiding the problem of lubricant leakage and environmental pollution. In addition, steel plate couplings have higher torsional stiffness and better transmission accuracy, making them particularly suitable for applications that require precise positioning.

Compared with elastic couplings such as plum blossom couplings and star couplings, Plate Couplings have a longer service life and better high-temperature performance. The non-metallic elastic components of elastic couplings are prone to aging in high-temperature environments and are prone to fatigue cracks under dynamic loads. The metal elastic components of the steel plate coupling are not affected by temperature and most chemicals, and can work reliably in more demanding environments. However, elastic couplings usually perform better in vibration reduction and noise reduction, and are relatively cheaper, so they still have advantages in some ordinary applications that do not require high transmission accuracy.

Compared with universal couplings, Plate Couplings have better stability during high-speed operation. Although universal couplings can compensate for larger angular deviations, they generate additional vibration and noise during high-speed operation, and their efficiency is relatively low. The steel plate coupling runs smoothly with an efficiency of over 99.8%. However, in situations where large angle transmission is required, such as vehicle transmission systems, universal couplings are still an irreplaceable choice.

Compared with diaphragm couplings, the two are more similar in structure and performance, and both belong to metal flexible couplings. But steel plate couplings are usually composed of multiple independent steel plates, while diaphragm couplings use integral metal diaphragms. This makes the steel plate coupling have better "fail safe" characteristics when subjected to excessive loads - when one steel plate is damaged, other steel plates can still temporarily maintain transmission, while the entire diaphragm will immediately fail once it ruptures. However, diaphragm couplings may perform better in ultra-high speed applications because their overall structure is more conducive to dynamic balancing.

« Plate Couplings » Post Date: 2024/5/6

URL: https://m.rokee.com/tags/plate-couplings.html