Rokee is a chinese Laminated Membrane Couplings Manufacturer, provide Laminated Membrane Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Laminated Membrane Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Laminated Membrane Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

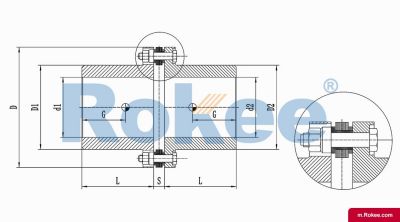

RLM Standard Single Section Small Metal Diaphragm Coupling

The RLM standard single section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working situations with a working speed not exceeding 5000rpm, and cannot compensate for radial errors.View More -

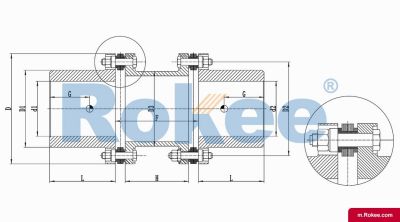

RLMD Standard Double Section Small Metal Diaphragm Coupling

The RLMD standard double section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working occasions with a working speed not exceeding 5000rpm.View More -

RLA Standard Single Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings,reliable choice for medium to low speed applications,but it cannot compensate for radial deviation.View More -

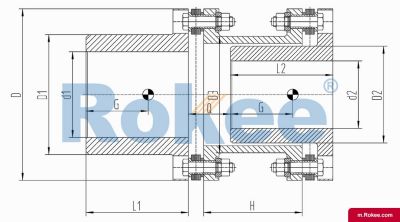

RLAD Standard Double Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications.View More -

RLAR Single Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

Single side shaft sleeve reverse installation design, suitable for occasions with limited shaft head distance.View More -

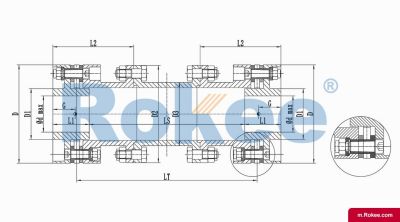

RLARD Double Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

The double-sided shaft sleeve reverse installation design is also applicable in situations where the distance from the shaft head is limited or the additional bending moment is smaller.View More -

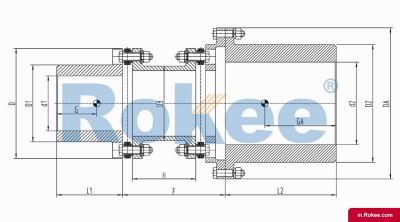

RLAF Large & Small Shaft Mounted Metal Diaphragm Coupling

The size difference design of the bilateral shaft sleeve is suitable for situations where the diameter difference between the two ends of the shaft is significant.View More -

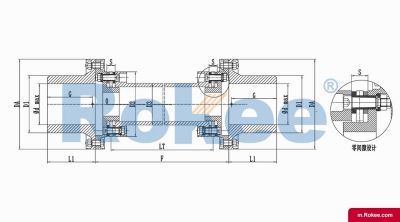

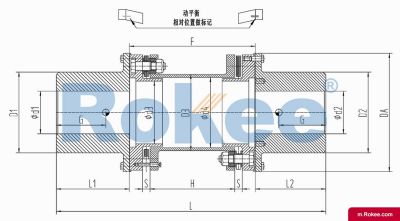

RLAT Super Long Wheelbase Metal Diaphragm Coupling

Adopting an intermediate shaft design, suitable for ultra long shaft spacing power transmission applications.View More -

RLQA No Flange Quick Installation Metal Diaphragm Coupling

Suitable for various industrial process pumps, fans, and other medium to low speed applications, with a maximum speed generally not exceeding 25000 rpm. It meets the requirements of API610/ISO14691 and is one of the first products for API applications.View More -

RLQF Flange Type Quick Installation Metal Diaphragm Coupling

Suitable for drum pressure fans, turbine compressors, and other high speed applications, with a maximum speed of up to 35000rpm.View More -

RLQU Improved Flange Quick Installation Metal Diaphragm Coupling

The improved RLQF has smaller additional bending moments and better performance. Suitable for drum pressure fans, turbine compressors, and other high speed applications.View More -

RLHD High Speed Metal Diaphragm Coupling

Suitable for higher speed applications, it also adopts a flexible component integrated assembly design, with a maximum speed of up to 42000rpm.View More -

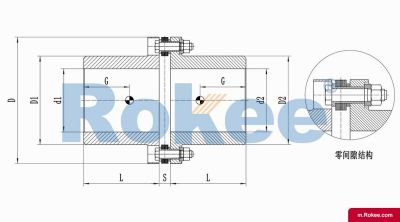

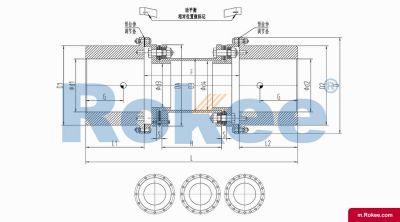

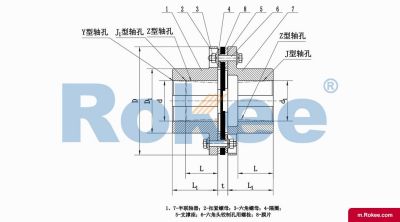

JMI Single Diaphragm Coupling With Counterbore

JMI metal diaphragm coupling adopts the single-piece design, suitable for short distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

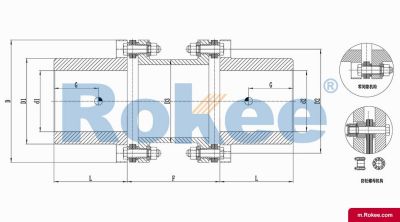

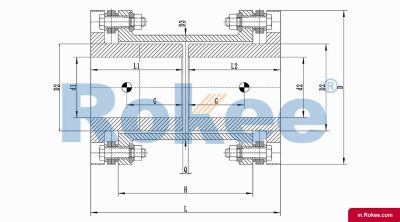

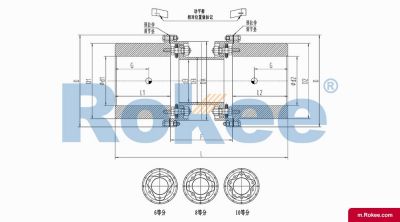

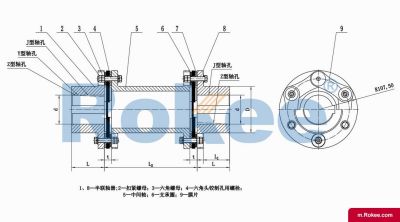

JMIJ Double Diaphragm Coupling With Intermediate Shaft

JMIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

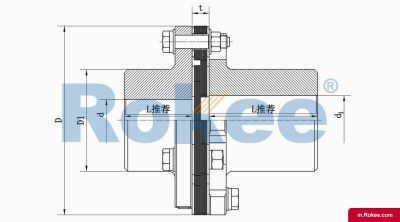

JMII Single Diaphragm Coupling Without Counterbore

JMII metal diaphragm coupling also adopts the single-piece design but has no counterbore, suitable for short distance transmission, with more compact structure.View More -

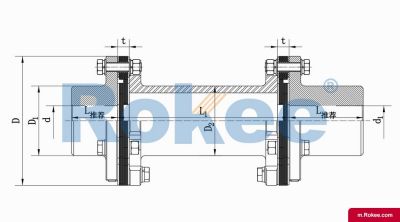

JMIIJ Double Diaphragm Coupling With Intermediate Shaft

JMIIJ Diaphragm Coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at both ends have no counterbore.View More

The laminated membrane coupling is a high-performance metal elastic element flexible coupling, consisting of a membrane group composed of multiple layers of stainless steel thin plates stacked together and connected by bolts in a staggered manner. The core principle is to compensate for axial, radial, and angular deviations between two axes through the elastic deformation of the diaphragm (with a compensation capability of up to 1.5 ° angular displacement), achieving seamless torque transmission.

Typical structures are divided into:

Single membrane type: suitable for low eccentricity scenarios, with a simple structure but limited compensation capability.

Double membrane type: By synergistically deforming two sets of membranes, it can simultaneously handle multi-directional deviations and has stronger compensation capabilities (such as JZM and SJM series).

Core Features and Advantages

High performance compensation capability

The angular displacement compensation amount is twice that of the gear coupling, and the radial displacement reaction force is small, allowing for axial deviation of ± 0.5mm and radial deviation of ± 1.5mm (taking DJM type as an example).No lubrication design

Metal film does not require lubrication, avoiding oil pollution, and is suitable for industries with high cleanliness requirements such as food and chemical.Resistant to extreme environments

The working temperature range is -80 ℃ to+300 ℃, resistant to acid and alkali corrosion (such as couplings used in chemical pumps), and resistant to impact and vibration (such as wind power equipment).Efficient transmission

The transmission efficiency is as high as 99.86%, and the torque transmission range is from 10Nm to 8.1 million Nm, suitable for high-speed and high-power scenarios (with a maximum speed of 6000r/min).

Key design parameters and selection

Diaphragm type

Linkage type: commonly used in high torque scenarios, such as metallurgical machinery.

Whole piece: suitable for precision transmission, such as aviation power systems.Installation parameters

Bolt fit clearance: 0.20-0.30mm (key section for transmitting torque).

Gap between buffer sleeves: 0.5-0.7mm (for positioning membranes).Selection steps

Calculate peak torque (including acceleration and deceleration conditions);

Verify the size of the shaft hole (recommended J1 standardized shaft hole);

Choose a single/double membrane structure based on the deviation.

Application scenarios

Energy sector: generator sets, wind turbines (such as expansion sleeve membrane couplings).

Industrial equipment: compressors, pumps (chemical pumps require corrosion-resistant diaphragms).

Precision Machinery: CNC Machine Tool Servo System (Zero Rotary Clearance Design).

Transportation: Ship propulsion system (anti seawater corrosion characteristics).

Laminated membrane couplings with their unique performance advantages, are gradually replacing traditional gear couplings and becoming the preferred solution for modern industrial transmission. The correct selection and standardized installation are the key to its effectiveness.

« Laminated Membrane Couplings » Post Date: 2024/5/6

URL: https://m.rokee.com/tags/laminated-membrane-couplings.html