Rokee is a chinese Flexible Disc Couplings Manufacturer, provide Flexible Disc Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Flexible Disc Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Flexible Disc Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

RLM Standard Single Section Small Metal Diaphragm Coupling

The RLM standard single section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working situations with a working speed not exceeding 5000rpm, and cannot compensate for radial errors.View More -

RLMD Standard Double Section Small Metal Diaphragm Coupling

The RLMD standard double section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working occasions with a working speed not exceeding 5000rpm.View More -

RLA Standard Single Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings,reliable choice for medium to low speed applications,but it cannot compensate for radial deviation.View More -

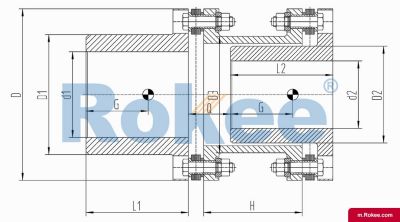

RLAD Standard Double Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications.View More -

RLAR Single Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

Single side shaft sleeve reverse installation design, suitable for occasions with limited shaft head distance.View More -

RLARD Double Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

The double-sided shaft sleeve reverse installation design is also applicable in situations where the distance from the shaft head is limited or the additional bending moment is smaller.View More -

RLAF Large & Small Shaft Mounted Metal Diaphragm Coupling

The size difference design of the bilateral shaft sleeve is suitable for situations where the diameter difference between the two ends of the shaft is significant.View More -

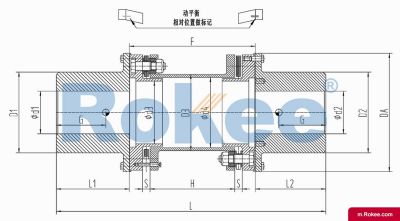

RLAT Super Long Wheelbase Metal Diaphragm Coupling

Adopting an intermediate shaft design, suitable for ultra long shaft spacing power transmission applications.View More -

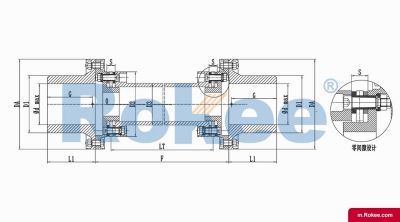

RLQA No Flange Quick Installation Metal Diaphragm Coupling

Suitable for various industrial process pumps, fans, and other medium to low speed applications, with a maximum speed generally not exceeding 25000 rpm. It meets the requirements of API610/ISO14691 and is one of the first products for API applications.View More -

RLQF Flange Type Quick Installation Metal Diaphragm Coupling

Suitable for drum pressure fans, turbine compressors, and other high speed applications, with a maximum speed of up to 35000rpm.View More -

RLQU Improved Flange Quick Installation Metal Diaphragm Coupling

The improved RLQF has smaller additional bending moments and better performance. Suitable for drum pressure fans, turbine compressors, and other high speed applications.View More -

RLHD High Speed Metal Diaphragm Coupling

Suitable for higher speed applications, it also adopts a flexible component integrated assembly design, with a maximum speed of up to 42000rpm.View More -

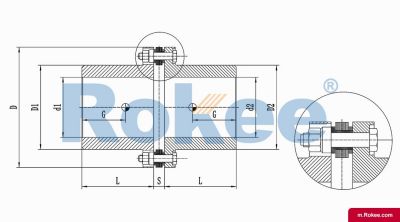

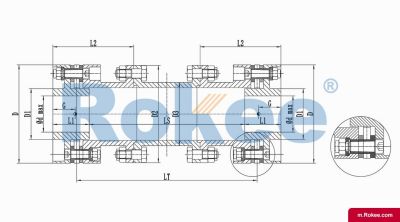

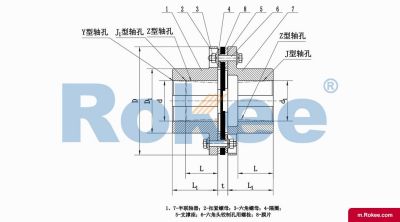

JMI Single Diaphragm Coupling With Counterbore

JMI metal diaphragm coupling adopts the single-piece design, suitable for short distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

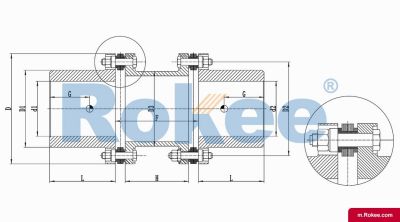

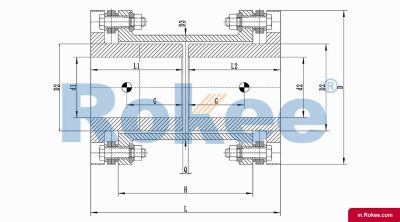

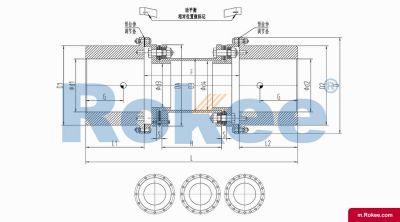

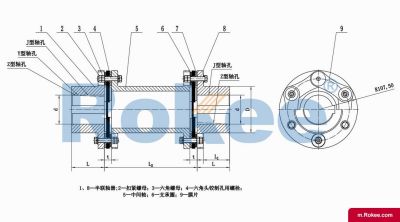

JMIJ Double Diaphragm Coupling With Intermediate Shaft

JMIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

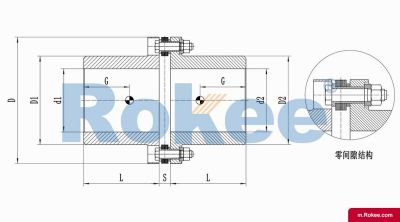

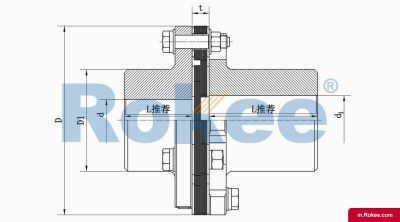

JMII Single Diaphragm Coupling Without Counterbore

JMII metal diaphragm coupling also adopts the single-piece design but has no counterbore, suitable for short distance transmission, with more compact structure.View More -

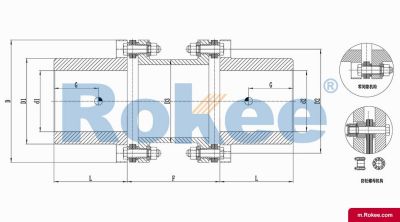

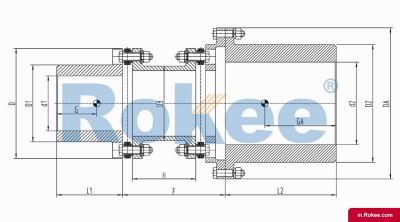

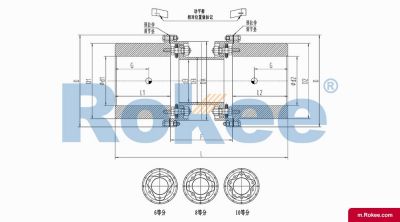

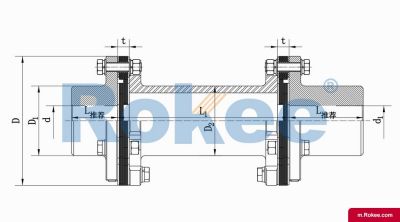

JMIIJ Double Diaphragm Coupling With Intermediate Shaft

JMIIJ Diaphragm Coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at both ends have no counterbore.View More

Flexible disc coupling is a high-performance flexible coupling, whose core design concept is to compensate for shaft deviation and absorb vibration impact through the deformation of elastic elements. This type of coupling is particularly suitable for connecting mechanical equipment with uneven torque characteristics, such as internal combustion engines, reciprocating compressors, and cement mills. The elastic element of the flexible disc coupling usually has good linear deformation characteristics, excellent torsional vibration buffering performance, and can work stably in the temperature range of -30 ° C to+60 ° C.

Structurally, the flexible disc coupling is mainly composed of a metal wheel hub and a rubber elastic disc. The inner diameter of the rubber disc elastic element is firmly bonded to the wheel hub through vulcanization process, forming a whole structure. The wheel hub can be connected using a tapered fastening sleeve for easy installation and disassembly. The flange connection size of this type of coupling usually adopts SAE J620d standard, which has the characteristics of high standardization and good interchangeability. Its torque transmission range is wide, ranging from 330Nm to 40000Nm, which can meet the needs of transmission systems of different power levels.

Compared with traditional rigid couplings, flexible disc couplings have three significant advantages: firstly, they can compensate for installation deviations, including axial, radial, and angular displacements; The second is to effectively absorb vibration and impact, reduce the noise and vibration of the transmission system; Thirdly, there is no need for lubrication and maintenance, which reduces equipment downtime and maintenance costs. These characteristics make it widely used in fields such as industrial automation, energy equipment, and heavy machinery.

The core structural components of an flexible disc coupling include a metal hub, an elastic disc body, and connecting bolts. Metal wheels are usually made of high-strength alloy steel or aluminum alloy, and are precision machined to ensure a good fit with the shaft. The elastic disc body is made of specially formulated rubber material, which may be embedded with reinforcing fibers or metal skeleton to improve mechanical properties. The connecting bolts are made of high-strength alloy steel and have undergone anti-corrosion treatment on the surface to ensure long-term reliable connection.

From the perspective of working principle, the flexible disc coupling achieves power transmission and vibration absorption through multi-stage energy conversion. When the drive shaft rotates, torque is first transmitted to the elastic disc through the hub, and the rubber material undergoes shear deformation, converting some kinetic energy into elastic potential energy and storing it. As the rotation continues, this periodic deformation recovery process effectively smooths out torque fluctuations and reduces the impact load on the transmission system. flexible disc couplings perform well in compensating for axis deviations and can simultaneously handle three basic forms of displacement: axial displacement (usually ≤ 5mm), radial displacement (≤ 2mm), and angular displacement (≤ 1 °).

The dynamic characteristics of the coupling are also reflected in its nonlinear stiffness. Within the normal working range, the torsional stiffness of the elastic disc is relatively constant, but when the load exceeds the design value, the stiffness will significantly increase. This characteristic ensures the flexibility of daily operation and provides overload protection function. In addition, the internal friction of rubber molecules inside the coupling will produce a certain damping effect, which helps to suppress the resonance phenomenon of the transmission system. This is particularly important for working conditions with frequent start stop or forward and reverse changes.

The flexible disc coupling has a series of outstanding performance characteristics, which make it occupy an important position in the field of industrial transmission. The most prominent advantage is its excellent shock absorption and buffering ability, which can absorb up to 60% -70% of the impact energy and significantly reduce the damage of peak stress to key components such as bearings and gears. Test data shows that a properly configured flexible disc coupling can reduce the vibration amplitude of the transmission system by more than 40% and reduce noise by 15-20 decibels.

The flexible disc coupling adopts a modular design, which eliminates the need to move the connected machine equipment when replacing the rubber disc, greatly simplifying the maintenance process. The flange connection size of the coupling follows the standard, ensuring the universality and interchangeability of the product. In addition, the flexible disc coupling also has the same characteristics of clockwise and counterclockwise rotation, which is suitable for transmission systems that require bidirectional rotation.

Compared with other types of couplings, the flexible disc coupling performs outstandingly in terms of corrosion resistance and maintenance free performance. Its rubber components have good resistance to pollutants such as water and dust, allowing the coupling to work reliably in harsh environments such as outdoor, dusty, and humid conditions. Actual cases have shown that the average fault free working time of flexible disc couplings applied to port lifting equipment can reach over 30000 hours.

flexible disc couplings have formed multiple series of products through technological development, which can be divided into the following main types based on their structural characteristics and applicable working conditions:

The standard flexible disc coupling is the most universal model, which adopts an integral disc structure to balance various performance parameters. This type of specification covers a wide range and can meet most conventional transmission needs, especially suitable for rotating equipment such as fans and pumps that require vibration transmission to be relaxed. The reinforcement layer structure in its rubber components effectively disperses stress concentration and extends its service life.

The heavy-duty flexible disc coupling is specially developed for heavy industries such as metallurgy and mining, using a thicker elastic disc body to enhance impact resistance and durability. This model uses a special formula of heat-resistant rubber material, which can withstand a high temperature environment of 120 ℃ for a short period of time. It is suitable for equipment such as rolling mills and straightening machines that generate severe vibration and impact loads.

The quick installation type flexible disc coupling adopts an innovative open disc structure, which performs outstandingly in terms of installation convenience. This design allows for the replacement of the elastic disc body without the need for axial movement of the coupling during equipment maintenance, greatly saving downtime. It is particularly suitable for situations where space is limited or frequent maintenance is required, such as ship power systems, tunnel construction equipment, etc.

The typical application areas of flexible disc couplings include:

Energy equipment: wind turbines, diesel generators

Industrial machinery: compressors, pump sets, mixing equipment

Transportation: Ship propulsion system, locomotive transmission system

Heavy machinery: metallurgical rolling mills, mining machinery, cement equipment

Process industry: petrochemical, papermaking, food processing equipment

In the field of wind power generation, the flexible disc coupling connects the speed increasing gearbox and the generator set, and works on the elastic support at high altitude for a long time, which can compensate for the position deviation caused by changes in the transmission dimension chain. In steam turbine units, flexible disc couplings can adapt to high temperature and high humidity environments and high speed requirements, solving special structural design problems under open lubrication conditions.

Proper selection and installation are key to ensuring optimal performance of the flexible disc coupling. In the selection process, engineers need to consider the following key parameters comprehensively:

Torque requirements: including rated torque, peak torque, and starting torque

Speed Range: Operating Speed and Critical Speed Avoidance

Shaft diameter size: Ensure that the coupling matches the shaft diameter

Environmental conditions: temperature, humidity, corrosive media, etc

Deviation compensation: expected axial, radial, and angular deviations

Space limitations: radial and axial dimensions of installation space

When installing the flexible disc coupling, the correct alignment steps must be followed:

Preliminary inspection of all components of the coupling to ensure their integrity, cleaning of mating surfaces

Use specialized tools for axis alignment to ensure that the deviation is within the allowable range

Tighten the connecting bolts evenly and step by step according to the torque values provided by the manufacturer

After installation, manually turn the disc to check for any abnormal friction or jamming

Observation of vibration and noise during no-load trial operation

The daily maintenance of flexible disc couplings is relatively simple, mainly including:

Regularly check the tightening status of bolts to prevent loosening

Observe whether the elastic disc body has defects such as aging and cracks

Monitor operating temperature, abnormal temperature rise may indicate overload or poor alignment

Record vibration data, establish trend analysis to predict lifespan

During maintenance, it should be noted that different types of flexible disc couplings may have specific disassembly and assembly requirements. For quick release designs, the disc body can usually be replaced without the need for axial movement of equipment; Traditional models may require specialized top screws or hydraulic tools for disassembly. Regardless of the type, rough disassembly methods such as hammering should be avoided to prevent damage to the mating surface.

« Flexible Disc Couplings » Post Date: 2024/5/6

URL: https://m.rokee.com/tags/flexible-disc-couplings.html