Rokee is a chinese Double Diaphragm Couplings Manufacturer, provide Double Diaphragm Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Double Diaphragm Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Double Diaphragm Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

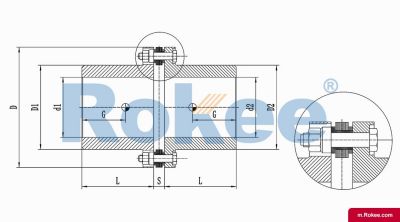

RLM Standard Single Section Small Metal Diaphragm Coupling

The RLM standard single section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working situations with a working speed not exceeding 5000rpm, and cannot compensate for radial errors.View More -

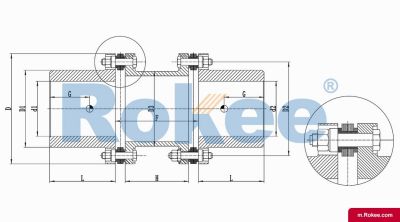

RLMD Standard Double Section Small Metal Diaphragm Coupling

The RLMD standard double section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working occasions with a working speed not exceeding 5000rpm.View More -

RLA Standard Single Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings,reliable choice for medium to low speed applications,but it cannot compensate for radial deviation.View More -

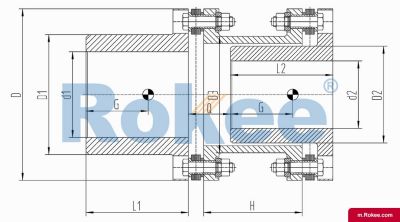

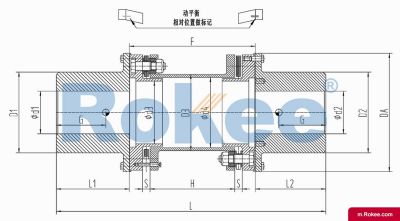

RLAD Standard Double Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications.View More -

RLAR Single Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

Single side shaft sleeve reverse installation design, suitable for occasions with limited shaft head distance.View More -

RLARD Double Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

The double-sided shaft sleeve reverse installation design is also applicable in situations where the distance from the shaft head is limited or the additional bending moment is smaller.View More -

RLAF Large & Small Shaft Mounted Metal Diaphragm Coupling

The size difference design of the bilateral shaft sleeve is suitable for situations where the diameter difference between the two ends of the shaft is significant.View More -

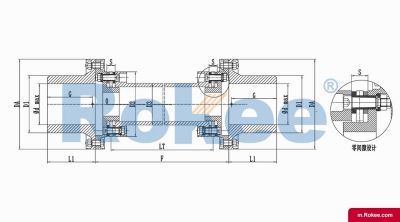

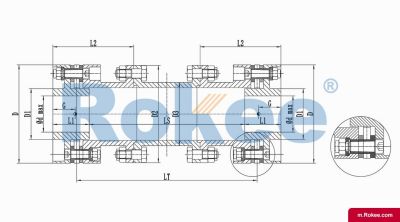

RLAT Super Long Wheelbase Metal Diaphragm Coupling

Adopting an intermediate shaft design, suitable for ultra long shaft spacing power transmission applications.View More -

RLQA No Flange Quick Installation Metal Diaphragm Coupling

Suitable for various industrial process pumps, fans, and other medium to low speed applications, with a maximum speed generally not exceeding 25000 rpm. It meets the requirements of API610/ISO14691 and is one of the first products for API applications.View More -

RLQF Flange Type Quick Installation Metal Diaphragm Coupling

Suitable for drum pressure fans, turbine compressors, and other high speed applications, with a maximum speed of up to 35000rpm.View More -

RLQU Improved Flange Quick Installation Metal Diaphragm Coupling

The improved RLQF has smaller additional bending moments and better performance. Suitable for drum pressure fans, turbine compressors, and other high speed applications.View More -

RLHD High Speed Metal Diaphragm Coupling

Suitable for higher speed applications, it also adopts a flexible component integrated assembly design, with a maximum speed of up to 42000rpm.View More -

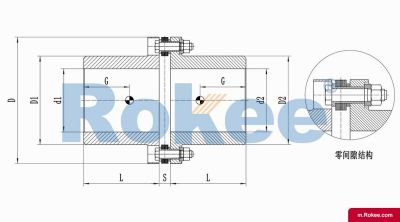

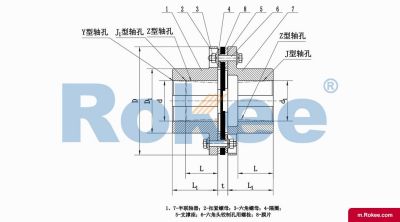

JMI Single Diaphragm Coupling With Counterbore

JMI metal diaphragm coupling adopts the single-piece design, suitable for short distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

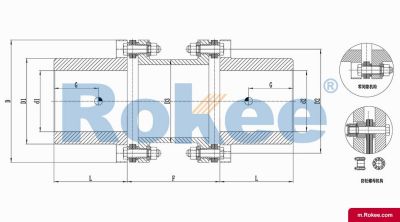

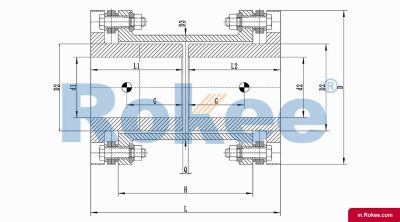

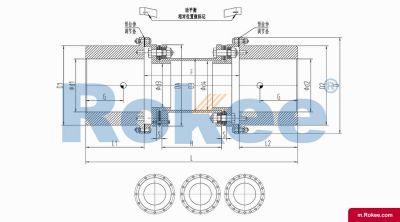

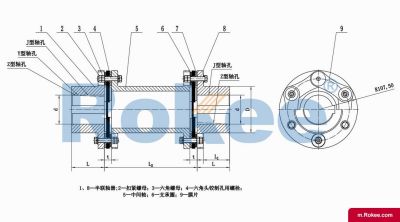

JMIJ Double Diaphragm Coupling With Intermediate Shaft

JMIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

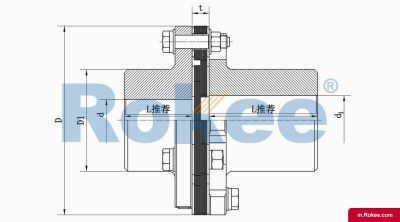

JMII Single Diaphragm Coupling Without Counterbore

JMII metal diaphragm coupling also adopts the single-piece design but has no counterbore, suitable for short distance transmission, with more compact structure.View More -

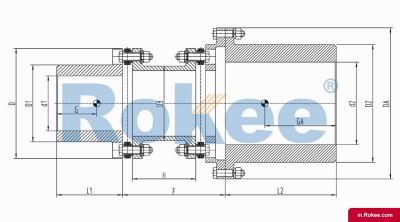

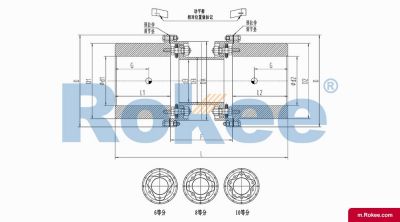

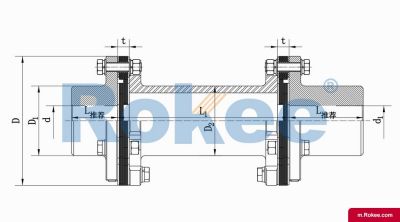

JMIIJ Double Diaphragm Coupling With Intermediate Shaft

JMIIJ Diaphragm Coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at both ends have no counterbore.View More

Double diaphragm coupling is a flexible coupling with multi-layer stainless steel diaphragm group as the core component, belonging to a type of metal elastic element coupling. It forms an elastic deformation structure by connecting two sets of staggered membranes and bolts, which can effectively compensate for the axial, radial, and angular relative displacement between the transmission shaft systems. This type of coupling has a wide range of applications in the industrial transmission field, especially suitable for situations that require high precision, high speed, and harsh working conditions.

The core component of the double diaphragm coupling is a diaphragm group composed of multiple layers of stainless steel thin plates stacked together, and each group of diaphragms is connected between the two halves of the coupling by high-strength bolts in a staggered manner. According to the different shapes of the membrane, it can be divided into two main types: linkage type and integral type.

Its working principle relies on the elastic deformation of the diaphragm to compensate for the relative displacement of the two connected axes. When there is misalignment between the two axes, the diaphragm absorbs these deviations through its own flexible deformation, thereby reducing the additional load on the bearings and shaft system. This design enables the double diaphragm coupling to simultaneously compensate for axial displacement (up to ± 0.5mm), radial displacement (up to ± 0.2mm), and angular displacement (up to 1.5 °).

The double diaphragm coupling has multiple excellent technical features:

Non lubrication design: The all metal structure does not require lubrication, avoiding lubricant leakage and contamination issues, making it particularly suitable for industries with high cleanliness requirements such as food and medicine.

High transmission efficiency: The transmission efficiency can reach 99.86%, with almost no energy loss, far higher than the gear coupling that requires lubrication.

Resistant to harsh environments: Made of stainless steel material, it has acid and alkali resistance, anti-corrosion properties, and a wide working temperature range (-80 ℃ to+300 ℃).

High speed capability: High balance accuracy, with a maximum speed of 6000r/min, suitable for high-speed transmission applications.

Zero backlash: Provides precise transmission ratio, no reverse backlash, suitable for precision transmission systems.

Long life maintenance free: No wear and tear parts, the service life can reach more than 10 years under normal use conditions, and there is basically no need for maintenance.

Vibration damping characteristics: The diaphragm group can effectively absorb and buffer vibrations, reducing system noise.

Double diaphragm couplings can be divided into various models and series according to their structure and application:

JMI type: standard double diaphragm coupling, suitable for general industrial transmission

JMIJ type: with an extended intermediate shaft, suitable for long wheelbase connections

JMII type: high torque type, with a static torsional stiffness of up to 3400N · m/rad

JMIIJ type: high torque with intermediate shaft type

SJM type: special high temperature and high pressure type, suitable for extreme working conditions

The static torsional stiffness range of these models is usually between 450-3400N · m/rad, and users can choose the appropriate model according to the stiffness requirements of the transmission system.

The application range of double diaphragm couplings is extremely wide, covering almost all industrial fields that require precision transmission:

Energy and electricity: generator sets, steam turbines, boiler feedwater pumps

Petrochemical industry: compressors, chemical pumps, petroleum machinery

Metallurgical mines: rolling mills, mining machinery, metallurgical equipment

Marine aviation: ship power system, helicopter transmission system

General machinery: fans, water pumps, printing machinery, textile machinery

Precision machinery: CNC machine tools, servo systems, force measuring devices

It is worth mentioning that in high-power fan systems, double diaphragm couplings can perfectly replace hydraulic couplings, achieving more efficient transmission. Installation only takes one day and has minimal impact on production.

The correct installation is the key to ensuring the long-term reliable operation of the double diaphragm coupling:

Bolt installation direction: It must be inserted from the outside of the flange hole to ensure the surface integrity of the bolt and flange fitting section.

Coordination gap control: The gap between the bolt and the flange small hole should be controlled at 0.20-0.30mm, and the gap between the buffer sleeve and the inner hole of the diaphragm rivet should be 0.5-0.7mm.

Alignment adjustment: after installation, the alignment of the two shafts shall be checked, and the radial deviation, angular deviation and axial deviation shall be within the allowable range.

Tightening sequence: The bolts should be tightened in stages in diagonal order, and the final torque should reach the specified value.

Regular inspection: During the initial operation, the bolt tightening status should be checked regularly, and during long-term operation, attention should be paid to observing for any abnormal vibration or noise.

Choosing a suitable double diaphragm coupling requires consideration of the following key parameters:

Torque characteristics: including rated torque, peak torque, and starting torque. The rated torque of the coupling should be greater than the maximum working torque of the system.

Speed range: The working speed should be within the allowable speed range of the coupling, taking into account the influence of centrifugal force.

Deviation compensation capability: Select a model with sufficient compensation capability based on the expected shaft deviation.

Environmental conditions: Consider the impact of environmental factors such as temperature, humidity, and corrosive media on materials.

Space limitation: The external dimensions and weight of the coupling should meet the installation space requirements.

Special requirements: such as explosion-proof, food grade, insulation and other special application requirements.

The double diaphragm coupling has become an indispensable key component in modern industrial transmission systems due to its excellent performance and reliability. It perfectly balances the relationship between transmission accuracy, compensation capability, and durability, demonstrating irreplaceable advantages in numerous application scenarios. With the continuous advancement of manufacturing technology, double diaphragm couplings will continue to expand their application boundaries, providing more efficient and reliable solutions for industrial transmission.

For users, correct selection, standardized installation, and appropriate maintenance are key to fully utilizing the performance of double diaphragm couplings. It is recommended to consult professional technicians when selecting, and choose the most suitable product model and configuration based on specific working conditions.

« Double Diaphragm Couplings » Post Date: 2024/5/8

URL: https://m.rokee.com/tags/double-diaphragm-couplings.html