Rokee is a chinese Pump Tyre Couplings Manufacturer, provide Pump Tyre Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Pump Tyre Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Pump Tyre Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

LLA Tyre Coupling

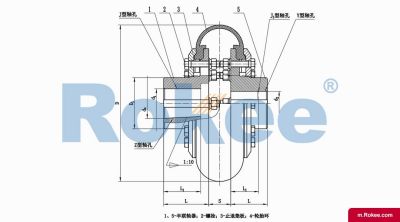

The LLA Tyre Coupling uses two semi-couplings to connect both sides of the elastic tyre body through internal pressing plates and bolts, making it easy to replace the elastic tyre body. The LLA Tyre Coupling is a kind of high elastic coupling, with good damping buffer and superior offset compensation performance.The working temperature of 20~80 degrees Celsius, transmitting torque 10~20000NM, suitable for damp, dust, shock, vibration, reversing the changeable and frequent starting working conditions, and convenient assembly and disassembly, no lubrication, durable and reliable. Non standard couplings are made in accordance with special needs. In overloading work and half coupling, there will be no malignant accidents.View More -

LLB Tyre Coupling

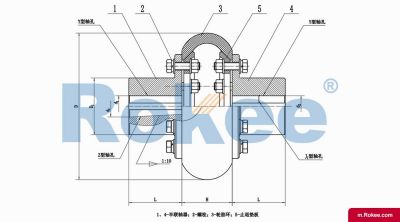

The LLB Tyre Coupling is a kind of high elastic coupling, with good damping buffer and superior offset compensation performance. The working temperature of 20~80 degrees Celsius, transmitting torque 10~20000NM, suitable for damp, dust, shock, vibration, reversing the changeable and frequent starting working conditions, and convenient assembly and disassembly, no lubrication, durable and reliable. Non standard couplings are made in accordance with special needs. In overloading work and half coupling, there will be no malignant accidents.View More -

UL Tyre Coupling

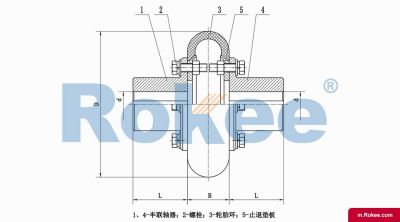

UL Tyre Coupling adopts the structure of vulcanizing and bonding the tyre body with the metal connecting plate with threaded holes, which is then directly connected to the two semi-couplings by bolts for torque transmission and other displacement compensation.UL Tyre Couplings are flexible shaft coupling. UL type tire has good buffering performance. Operating temperature: -20~+80℃. Torque range: 10~25000N.M.UL Tyre Coupling mainly used in damp, dusty, vibration working environment. Because the elastic part is the whole tire, so, easy to disassemble and assemble. No lubrication is required.View More

As a highly elastic coupling device, tyre couplings play a crucial role in modern industrial transmission systems. With its unique rubber elastic element design, it can effectively absorb vibration and compensate for shaft offset while transmitting torque, providing a smooth and reliable connection solution for various mechanical equipment.

tyre coupling is a mechanical transmission device that relies on rubber elastic elements to achieve flexible connection. Its core design concept is to absorb impact, vibration, and compensate for shaft deviation through elastic deformation. Structurally, the tyre coupling mainly consists of three parts: two flange plates with shaft holes (usually made of 45 # steel or cast steel), a rubber tire body as an elastic element, and a high-strength bolt assembly connecting the two. Among them, the rubber tire body is tightly integrated with the internal steel skeleton through vulcanization process, and nuts are welded at the bolt holes on the skeleton. This design ensures both the reliability of the connection and the durability of the elastic elements.

According to structural characteristics and application requirements, tyre couplings can be classified into various types. Convex and concave are two basic classifications, among which convex can be further divided into three variants: skeletal integral, boneless integral, and radial incision. The integral structure with a skeleton has higher torsional stiffness and load-bearing capacity, making it suitable for heavy-duty conditions; The boneless integral design is softer and provides better shock absorption performance; The radial notch type performs well in specific angle compensation requirements. From the perspective of model specifications, UL type, LLB type, and LLA type are the three most commonly used tyre couplings in the industrial field, each with unique design features and application focuses.

The working principle of tyre coupling is based on the principles of elastic deformation mechanics and friction transmission. Its unique design enables it to effectively cope with various complex working conditions while transmitting torque. When power is input from the drive side flange, torque is transmitted to the rubber tire body through bolt connections, and the tire body immediately undergoes torsional deformation and transmits torque to the driven side flange. In this process, the elastic properties of rubber materials play a key role, not only achieving flexible power transmission, but also consuming vibration energy through internal damping.

From a mechanical perspective, the torque transmission capability of tyre couplings mainly depends on two mechanisms: one is the static friction force generated between the bolt preload force and the tire ring and flange end face, and the other is the shear strength of the rubber material itself. In normal working conditions, friction plays the main role in torque transmission, while when the system encounters impact loads, the shear deformation of rubber provides additional buffering capacity. This dual mechanism enables the tyre coupling to stably transmit power during normal operation and protect the transmission system in case of sudden overload. It is worth noting that as the transmitted torque increases, rubber tires will produce corresponding torsion angles. A well-designed coupling should ensure that the torsion angle does not exceed 4-5 degrees at the maximum working torque to avoid excessive deformation affecting performance and lifespan.

The most prominent performance feature of tyre couplings is their excellent displacement compensation ability. In terms of axial displacement, typical specifications allow for a compensation amount of ± 5mm; The radial displacement compensation capability is generally ± 2mm, while the angular deviation compensation range can reach ± 1 degree. This multi-directional compensation capability makes tyre couplings particularly suitable for applications with installation errors or shaft displacement during operation, such as changes in shaft position caused by thermal expansion. The coupling adapts to these deviations through the elastic deformation of rubber components, significantly reducing the additional load on bearings and shafts, and extending the overall service life of the equipment.

However, tyre couplings can also generate some special mechanical phenomena during operation that require special attention. As the relative twist angle between the two axes increases, the tire shape will twist, resulting in a slight decrease in axial size, which will generate significant additional axial force on both axes. Under high-speed operating conditions (usually exceeding 1000rpm), the outer edge of the tire expands outward due to centrifugal force, further increasing this additional axial force. Research has shown that in extreme cases, this additional axial force can reach 15-20% of the rated torque, significantly affecting the bearing life. To address this issue, advanced installation methods suggest applying reverse stress in advance during static installation, causing the tire body to undergo pre deformation opposite to its working state. This can partially offset the additional axial force generated during actual operation and significantly improve the working conditions of the bearing.

Another key mechanical characteristic is the dynamic response characteristics of tyre couplings. Due to the viscoelasticity of rubber materials, the response of tyre couplings under alternating torque exhibits a certain hysteresis, which enables them to effectively dampen the torsional vibration of the system. Experimental data shows that high-quality tyre couplings can absorb 30-40% of vibration energy and reduce the peak load of the transmission system by 20-30%. This feature makes tyre couplings an ideal choice for applications with pulsating loads or frequent start stop requirements, such as piston pumps, compressors, and other equipment.

tyre couplings, with their unique structural design and material properties, have demonstrated various performance advantages in the industrial transmission field, making them stand out among many types of couplings. From the perspective of performance characteristics, high elasticity and shock absorption capacity are the most prominent advantages. Rubber tire bodies can undergo elastic deformation, absorb and dissipate vibration energy when subjected to impact loads. Experimental data shows that high-quality tyre couplings can reduce the peak impact load of the system by more than 30%. This feature makes it particularly suitable for equipment with pulsating loads such as plunger pumps, compressors, etc., as well as for working conditions that require frequent start-up or forward and reverse rotation, such as cranes and conveying equipment.

Another major advantage of tyre couplings is their excellent displacement compensation capability. Typical technical parameters show that UL type tyre couplings can compensate for axial displacement ± 5mm, radial displacement ± 2mm, and angular deviation ± 1 °. This multi-directional compensation capability greatly reduces the requirements for equipment installation accuracy and effectively alleviates shaft offset problems caused by foundation settlement or thermal deformation. Unlike gear couplings and other designs that require internal sliding to compensate for deviations, tyre couplings rely entirely on the deformation of elastic elements to achieve displacement compensation, without relative sliding parts, thus requiring no lubrication and producing no wear particles. This feature makes them particularly suitable for industries with high cleanliness requirements such as food and medicine.

From a technical parameter perspective, the torque transmission capability of tyre couplings covers a wide range. The standard product series ranges from a minimum of 10N · m to a maximum of 25000 N · m, which can basically meet the needs of most industrial applications. Taking the commonly used UL model as an example, the nominal torque of UL1 model is 10N · m, with a shaft hole diameter of 11mm; while UL18 model can reach 25000N · m, with a shaft hole diameter of 180mm. In terms of speed capability, the allowable speed range of tyre couplings is usually between 800-5000rpm, depending on the specification size. Smaller couplings can achieve higher speeds. It is worth noting that due to the characteristics of rubber materials, the working temperature range of tyre couplings is generally -20 ℃ to 80 ℃. If it exceeds this range, special rubber formulas or other types of couplings should be considered.

Maintenance free design is another important feature that makes tyre couplings popular. Unlike gear couplings, chain couplings, and other types that require regular lubrication, tyre couplings do not require lubrication and maintenance at all, greatly reducing long-term usage costs. On site data shows that under normal operating conditions, the service life of high-quality tyre couplings can reach more than 5 years, during which almost no maintenance is required except for regular inspections of bolt tightening status. This characteristic makes tyre couplings particularly suitable for installation in locations that are difficult to access or maintain, such as high-altitude equipment, tunnel machinery, etc.

« Pump Tyre Couplings » Post Date: 2024/5/6

URL: https://m.rokee.com/tags/pump-tyre-couplings.html