Rokee is a chinese Diaphram Couplings Manufacturer, provide Diaphram Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Diaphram Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Diaphram Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

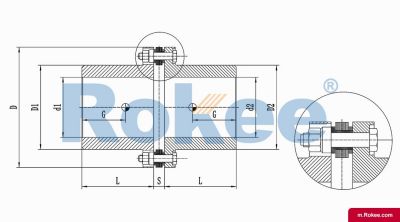

RLM Standard Single Section Small Metal Diaphragm Coupling

The RLM standard single section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working situations with a working speed not exceeding 5000rpm, and cannot compensate for radial errors.View More -

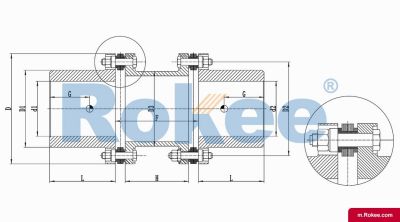

RLMD Standard Double Section Small Metal Diaphragm Coupling

The RLMD standard double section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working occasions with a working speed not exceeding 5000rpm.View More -

RLA Standard Single Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings,reliable choice for medium to low speed applications,but it cannot compensate for radial deviation.View More -

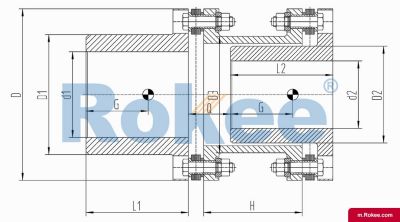

RLAD Standard Double Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications.View More -

RLAR Single Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

Single side shaft sleeve reverse installation design, suitable for occasions with limited shaft head distance.View More -

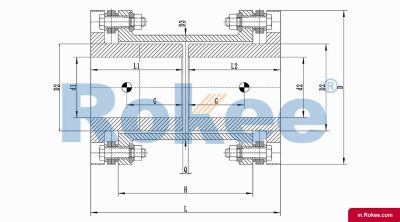

RLARD Double Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

The double-sided shaft sleeve reverse installation design is also applicable in situations where the distance from the shaft head is limited or the additional bending moment is smaller.View More -

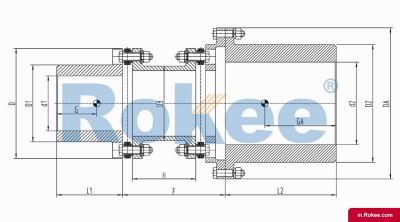

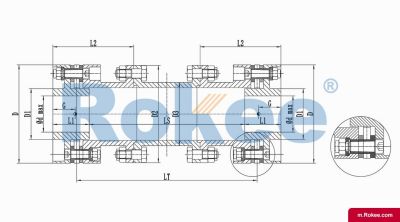

RLAF Large & Small Shaft Mounted Metal Diaphragm Coupling

The size difference design of the bilateral shaft sleeve is suitable for situations where the diameter difference between the two ends of the shaft is significant.View More -

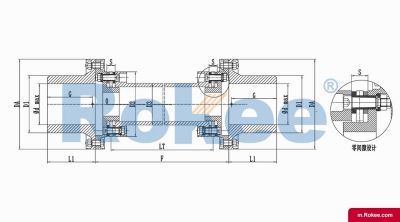

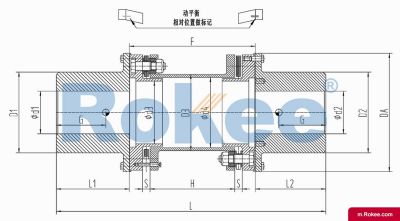

RLAT Super Long Wheelbase Metal Diaphragm Coupling

Adopting an intermediate shaft design, suitable for ultra long shaft spacing power transmission applications.View More -

RLQA No Flange Quick Installation Metal Diaphragm Coupling

Suitable for various industrial process pumps, fans, and other medium to low speed applications, with a maximum speed generally not exceeding 25000 rpm. It meets the requirements of API610/ISO14691 and is one of the first products for API applications.View More -

RLQF Flange Type Quick Installation Metal Diaphragm Coupling

Suitable for drum pressure fans, turbine compressors, and other high speed applications, with a maximum speed of up to 35000rpm.View More -

RLQU Improved Flange Quick Installation Metal Diaphragm Coupling

The improved RLQF has smaller additional bending moments and better performance. Suitable for drum pressure fans, turbine compressors, and other high speed applications.View More -

RLHD High Speed Metal Diaphragm Coupling

Suitable for higher speed applications, it also adopts a flexible component integrated assembly design, with a maximum speed of up to 42000rpm.View More -

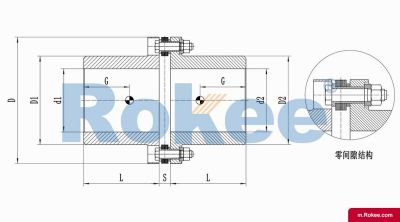

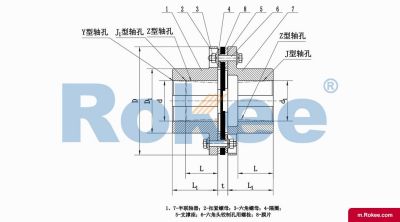

JMI Single Diaphragm Coupling With Counterbore

JMI metal diaphragm coupling adopts the single-piece design, suitable for short distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

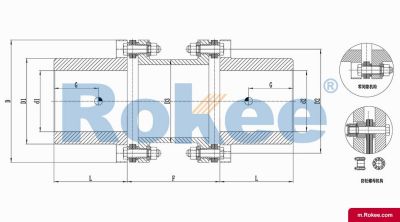

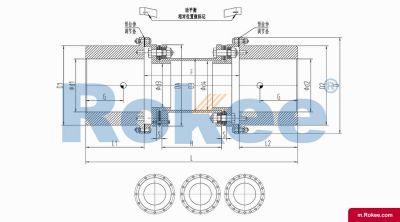

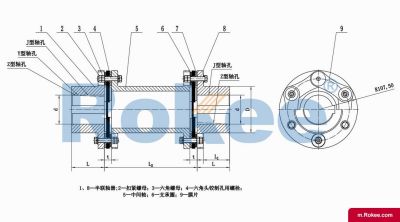

JMIJ Double Diaphragm Coupling With Intermediate Shaft

JMIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

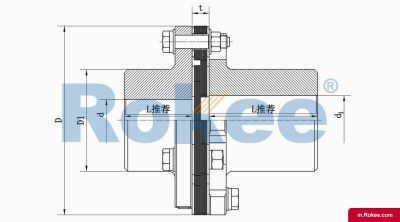

JMII Single Diaphragm Coupling Without Counterbore

JMII metal diaphragm coupling also adopts the single-piece design but has no counterbore, suitable for short distance transmission, with more compact structure.View More -

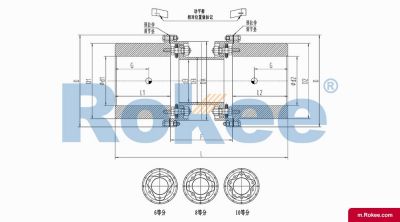

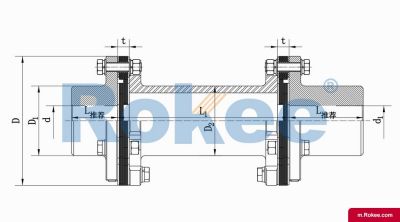

JMIIJ Double Diaphragm Coupling With Intermediate Shaft

JMIIJ Diaphragm Coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at both ends have no counterbore.View More

Diaphram Coupling is a high-performance metal strong element flexible coupling that uses metal elastic diaphragms as flexible elements to transmit torque. The Diaphram Coupling is composed of at least one diaphragm and two shaft sleeves. The diaphragm is made of stainless steel sheet and is fastened to the shaft sleeve with a pin, which generally does not loosen or cause backlash between the diaphragm and the shaft sleeve. Some membrane couplings consist of two membranes, while others consist of three membranes with one or two rigid elements in between, connected to the shaft sleeve on both sides. The Diaphram Coupling compensates for the relative displacement of the two shafts connected by the elastic deformation of the diaphragm, such as axial, radial, and angular offsets. This elastic deformation ability enables the Diaphram Coupling to adapt to various misalignment situations, ensuring smooth and efficient transmission.

The Diaphram Coupling has strong ability to compensate for misalignment of two axes. Compared with the gear coupling, its angular displacement can be twice as large, and the reaction force is small and the flexibility is large when it undergoes radial displacement. It has obvious shock absorption effect, no noise, no wear, and is suitable for occasions with strict requirements for vibration and noise. Suitable for working in high temperatures and harsh environments, able to operate safely under conditions of impact and vibration. At the same time, the Diaphram Coupling also has the characteristics of acid resistance, alkali resistance, and corrosion resistance. High transmission efficiency, especially suitable for medium and high-speed high-power transmission. Simple structure, light weight, small size, easy to assemble and disassemble, no need to move the machine, no lubrication required. It can accurately transmit speed, operate without slip, and can be used for transmission of precision machinery.

Diaphram Couplings are widely used in shaft transmission of various mechanical devices, such as water pumps, fans, compressors, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, chemical machinery, mining machinery, metallurgical machinery, aviation, high-speed power transmission systems for ships, steam turbines, piston power mechanical transmission systems, tracked vehicles, as well as high-speed and high-power mechanical transmission systems for generator sets.

When installing the Diaphram Coupling, it should be ensured that the axis deviation is within the allowable range to avoid deformation or damage to the coupling. At the same time, before installation, the end faces of both shafts should be cleaned and the fit of the end face key slots should be checked. After installation, all screws should be checked for looseness and repeatedly tightened to ensure they do not loosen. In addition, to prevent micro motion wear of the diaphragm during high-speed operation, solid lubricants such as molybdenum disulfide can be applied between the diaphragms or the diaphragm surface can be treated with anti wear coatings.

In the complex ecosystem of mechanical power transmission, couplings serve as the critical link that bridges rotating shafts, ensuring the seamless transfer of torque while accommodating inevitable misalignments. Among the diverse array of coupling technologies available today, the diaphragm coupling stands out as a high-performance solution, leveraging the elastic deformation of thin metallic diaphragms to achieve both reliable power transmission and precise misalignment compensation. Unlike traditional coupling designs that rely on lubricated components or elastomeric materials, diaphragm couplings offer a unique combination of robustness, low maintenance requirements, and environmental adaptability, making them indispensable in a wide range of industrial, aerospace, and marine applications.

At its core, a diaphragm coupling is a type of flexible coupling designed to connect two rotating shafts and transmit torque while compensating for three primary types of misalignment: angular misalignment (where the shafts are inclined relative to each other), parallel misalignment (where the shafts are offset radially), and axial misalignment (where the shafts move toward or away from each other). The key component that enables this dual function of torque transmission and misalignment compensation is the diaphragm itself—a thin, flexible disk typically made from high-strength metallic materials such as stainless steel, alloy steel, or Inconel. These diaphragms are usually arranged in sets, with each set consisting of multiple stacked plates, and are bolted alternately to the two halves of the coupling (known as hubs) that attach to the driving and driven shafts. The unique design of the diaphragm, often featuring corrugations or precision-cut patterns, allows it to flex and deform elastically under load, absorbing the misalignment between the shafts without introducing excessive stress or compromising torque transmission efficiency.

The working principle of a diaphragm coupling revolves around the mechanical interaction between the hubs and the diaphragms. When torque is applied to the driving shaft, it is transferred to the corresponding hub, which then distributes the torque to the diaphragm set via the bolted connections. The diaphragms transmit this torque through shear deformation, with the corrugated or patterned structure allowing for controlled flexing to accommodate misalignment. Importantly, this torque transmission occurs without any rotational clearance or backlash, ensuring precise motion control—a critical feature in applications requiring high positional accuracy. As the shafts rotate, the diaphragms continuously adjust to maintain the torque transfer path while compensating for dynamic misalignments that may arise from thermal expansion, shaft deflection, or mounting inaccuracies. Unlike gear couplings, which rely on interlocking teeth and require lubrication to reduce friction and wear, diaphragm couplings operate with no sliding or rolling components, eliminating the need for lubrication and the associated maintenance costs and risks of oil contamination.

The structural design of diaphragm couplings varies to suit different application requirements, with two primary configurations: single diaphragm and double diaphragm designs. Single diaphragm couplings consist of a single set of diaphragms connecting the two hubs directly, offering a compact design that is ideal for applications with limited installation space. However, their misalignment compensation capacity is relatively limited, particularly in terms of parallel misalignment. Double diaphragm couplings, on the other hand, incorporate two sets of diaphragms separated by a spacer or spool piece. This configuration significantly enhances the coupling’s ability to compensate for all types of misalignment, especially parallel and axial misalignments, and also reduces the reaction forces exerted on the shaft bearings—a key advantage in high-speed or high-precision applications. The spacer element in double diaphragm designs can also be customized in length to accommodate specific shaft-to-shaft distance requirements, providing greater flexibility in system design.

Material selection is a critical factor in determining the performance and service life of diaphragm couplings. The diaphragms themselves are typically manufactured from high-strength, corrosion-resistant metallic materials to withstand the cyclic stresses induced by torque transmission and repeated misalignment. Stainless steel is the most commonly used material due to its excellent combination of strength, ductility, and resistance to corrosion and high temperatures, making it suitable for most industrial environments. For extreme conditions, such as high-temperature applications in metallurgy or steam turbine systems, superalloys like Inconel are employed, as they retain their mechanical properties at temperatures exceeding 250°C. The hubs and spacer components are often made from aluminum alloy or carbon steel, balancing strength and weight to minimize the moment of inertia—an important consideration in high-speed applications where rotational inertia can affect system responsiveness and energy efficiency.

One of the most notable performance advantages of diaphragm couplings is their high torsional stiffness, which ensures minimal torsional deflection under load. This characteristic is particularly valuable in precision applications such as CNC machine tools, servo motor systems, and robotics, where even small amounts of torsional lag can compromise positional accuracy. Unlike elastomeric couplings, which exhibit significant torsional compliance, diaphragm couplings maintain a rigid torque transfer path, enabling precise control of the driven shaft’s speed and position. Additionally, diaphragm couplings offer a high torque capacity relative to their size, with nominal torque ratings ranging from 25 N·m to over 1,000,000 N·m, making them suitable for both small-scale precision machinery and large industrial equipment such as pumps, compressors, and turbines.

Another key advantage of diaphragm couplings is their maintenance-free operation. Since they have no sliding components and do not require lubrication, they eliminate the need for regular oil changes, greasing, or seal replacements—maintenance tasks that are not only time-consuming but also prone to human error. This maintenance-free design reduces downtime and operational costs, making diaphragm couplings particularly attractive in remote or hard-to-access applications, such as offshore wind turbines or marine propulsion systems. Furthermore, diaphragm couplings are resistant to a wide range of environmental factors, including temperature extremes (operating ranges typically from -20°C to 250°C or higher with specialized materials), moisture, dust, and corrosive media such as acids, alkalis, and saltwater. This environmental resilience makes them suitable for use in harsh industrial environments such as chemical plants, coastal facilities, and mining operations, where other types of couplings may degrade rapidly.

The absence of backlash is another critical performance feature of diaphragm couplings. Backlash, or the clearance between mating components, can cause undesirable motion delays and positioning errors in precision systems. In contrast, diaphragm couplings maintain a zero-backlash connection between the shafts, ensuring that torque is transmitted instantaneously and that the driven shaft responds precisely to changes in the driving shaft’s speed or position. This feature is essential in applications such as servo motor-driven conveyors, automated assembly lines, and precision machining centers, where tight control over motion is required to ensure product quality and process efficiency. Additionally, the rigid connection and absence of sliding components result in low vibration and noise levels, contributing to a quieter and more stable operating environment.

Diaphragm couplings find applications across a diverse range of industries, each leveraging their unique performance characteristics to address specific operational challenges. In the industrial machinery sector, they are widely used in pumps (particularly centrifugal and chemical pumps), fans, compressors, and blowers. These applications require reliable torque transmission, resistance to corrosive fluids, and minimal maintenance—all strengths of diaphragm couplings. For example, in chemical processing plants, diaphragm couplings are used to connect pump shafts to motor shafts, where their corrosion resistance prevents degradation from exposure to harsh chemicals, and their maintenance-free design reduces the risk of unplanned downtime that could disrupt production.

The aerospace and defense industries also rely heavily on diaphragm couplings, particularly in helicopter rotor systems, jet engine accessories, and missile guidance systems. In these applications, the high torsional stiffness, low weight, and resistance to extreme temperatures are critical. For instance, helicopter rotor systems require couplings that can transmit high torque while accommodating dynamic misalignments caused by rotor vibration and thermal expansion, and diaphragm couplings provide the necessary combination of flexibility and rigidity to ensure safe and reliable operation. Similarly, in jet engine accessories, the compact design and maintenance-free operation of diaphragm couplings make them ideal for use in the confined spaces of engine nacelles.

The automotive and transportation sectors utilize diaphragm couplings in advanced drivetrains, electric vehicle (EV) powertrains, and railway propulsion systems. In EVs, for example, diaphragm couplings connect the electric motor to the transmission, leveraging their high torsional stiffness to maximize power transfer efficiency and their low moment of inertia to improve the vehicle’s acceleration and energy economy. In railway applications, diaphragm couplings are used in diesel-electric locomotives to connect the engine to the generator, where their resistance to vibration and harsh environmental conditions (such as dust, moisture, and temperature fluctuations) ensures reliable performance over long service intervals.

Renewable energy systems, particularly wind and solar power, are increasingly adopting diaphragm couplings. In wind turbines, they are used to connect the gearbox to the generator, where their ability to compensate for misalignments caused by wind-induced vibration and thermal expansion is essential. The maintenance-free design of diaphragm couplings is particularly advantageous in wind turbines, which are often located in remote areas and require minimal downtime to ensure maximum energy production. In solar thermal power plants, diaphragm couplings are used in pump and fan systems that circulate heat transfer fluids, leveraging their high-temperature resistance to operate reliably in the extreme heat of solar collectors.

The selection of an appropriate diaphragm coupling for a specific application requires careful consideration of several key factors, including torque requirements, misalignment levels, operating speed, environmental conditions, and installation constraints. Torque capacity is the primary selection criterion, as the coupling must be capable of transmitting the maximum torque generated by the driving shaft without exceeding its fatigue limit. It is important to consider both the nominal torque (continuous operating torque) and the peak torque (transient torque during startup or load spikes) to ensure the coupling can withstand all operational conditions.

Misalignment compensation requirements must also be carefully evaluated. The type and magnitude of misalignment (angular, parallel, axial) will determine whether a single or double diaphragm design is required. For applications with significant parallel misalignment, a double diaphragm coupling with a spacer is typically recommended, as it can accommodate larger offsets than a single diaphragm design. Operating speed is another critical factor, as high-speed applications (exceeding 3000 rpm) require couplings with low moment of inertia and high dynamic balance accuracy to minimize vibration and prevent premature failure. Couplings used in high-speed applications should be dynamically balanced to precision levels such as G2.5 or higher, ensuring smooth operation even at maximum rotational speeds.

Environmental conditions, including temperature, humidity, and exposure to corrosive media, will influence material selection. High-temperature applications require diaphragms made from superalloys, while corrosive environments demand stainless steel or specially coated components. Installation constraints, such as available space and shaft-to-shaft distance, will determine the coupling’s size and configuration. For applications with limited space, a single diaphragm coupling may be the only viable option, while applications requiring longer shaft distances can benefit from a double diaphragm coupling with a custom-length spacer.

Proper installation and maintenance practices are essential to ensure the long-term performance and reliability of diaphragm couplings. During installation, precise shaft alignment is critical to minimize additional stress on the diaphragms. Even small amounts of misalignment beyond the coupling’s compensation capacity can lead to premature fatigue failure of the diaphragms. Alignment should be performed using precision tools such as laser alignment systems, which provide accurate measurements of angular and parallel misalignment. Additionally, the bolted connections between the diaphragms and hubs must be tightened to the specified torque to ensure a secure, uniform connection and prevent loosening during operation.

While diaphragm couplings are maintenance-free in terms of lubrication, regular inspection is still necessary to detect potential issues before they lead to failure. Routine inspections should include checking for signs of diaphragm wear, such as cracks, deformation, or discoloration (which may indicate overheating). The bolted connections should also be inspected periodically to ensure they remain tight, as loose bolts can cause uneven stress distribution and premature diaphragm failure. In applications with high vibration or frequent load cycles, more frequent inspections may be required to monitor the coupling’s condition. If a diaphragm is found to be damaged, it should be replaced promptly—preferably with a replacement diaphragm of the same material and design to maintain the coupling’s performance characteristics. Many diaphragm couplings feature a modular design, allowing for easy replacement of the diaphragm sets without requiring the entire coupling to be disassembled or the shafts to be moved, simplifying maintenance and reducing downtime.

Despite their numerous advantages, diaphragm couplings are not suitable for all applications. They have relatively high initial costs compared to some elastomeric couplings, making them less economical for low-torque, low-precision applications where cost is the primary concern. Additionally, their torsional stiffness, while an advantage in precision applications, means they offer limited vibration damping capabilities. In applications where significant shock loads or vibration isolation is required, elastomeric couplings or other flexible coupling types may be more appropriate. Furthermore, diaphragm couplings have a limited misalignment compensation range, and exceeding this range can lead to premature failure, so accurate alignment during installation is critical.

Looking to the future, advancements in materials science and manufacturing technologies are likely to further enhance the performance and versatility of diaphragm couplings. The development of new high-strength, lightweight materials, such as carbon fiber composites, may enable the production of diaphragm couplings with even higher torque capacities and lower moment of inertia, expanding their use in high-performance applications such as aerospace and racing vehicles. Additionally, the integration of advanced monitoring technologies, such as embedded sensors that detect diaphragm fatigue or misalignment in real time, could enable predictive maintenance, allowing potential issues to be addressed before they lead to unplanned downtime. These innovations are expected to further solidify the diaphragm coupling’s position as a critical component in modern power transmission systems.

In conclusion, diaphragm couplings represent a sophisticated and reliable solution for power transmission in a wide range of applications, offering a unique combination of high torsional stiffness, zero backlash, maintenance-free operation, and environmental adaptability. Their ability to transmit torque efficiently while compensating for misalignments makes them indispensable in precision machinery, industrial equipment, aerospace systems, and renewable energy applications. By understanding their working principles, performance characteristics, and selection criteria, engineers and system designers can leverage diaphragm couplings to optimize the performance, reliability, and efficiency of their power transmission systems. With ongoing advancements in materials and manufacturing, the role of diaphragm couplings in modern mechanical systems is likely to grow, addressing increasingly demanding operational requirements and enabling new technological innovations.

« Diaphram Couplings » Update Date: 2026/1/10

URL: https://m.rokee.com/tags/diaphram-couplings.html