Rokee is a chinese Universal Shafts Manufacturer, provide Universal Shafts processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Universal Shafts selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Universal Shafts is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

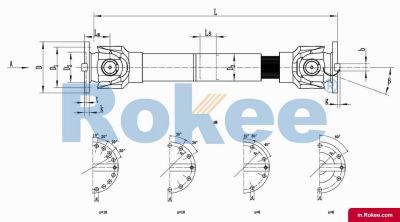

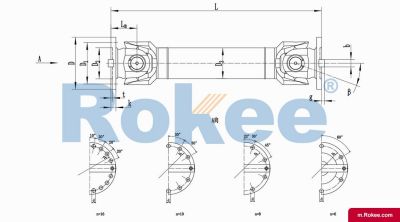

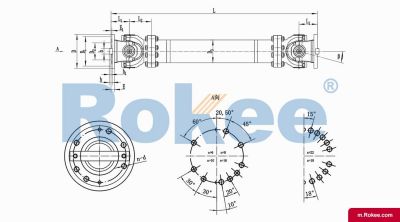

SWC-BH Cardan Shaft

SWC-BH standard telescopic welded universal joint couplingView More -

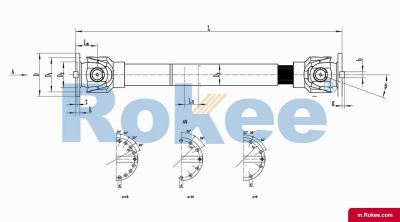

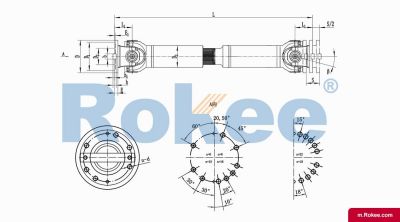

SWC-CH Cardan Shaft

SWC-CH long telescopic welded universal joint couplingView More -

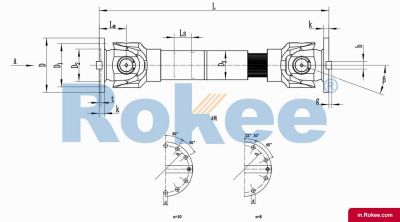

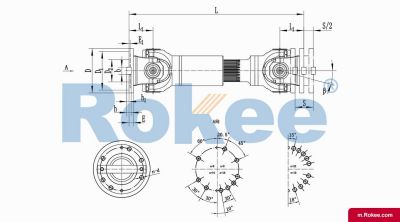

SWC-DH Cardan Shaft

SWC-DH short telescopic welded universal joint couplingView More -

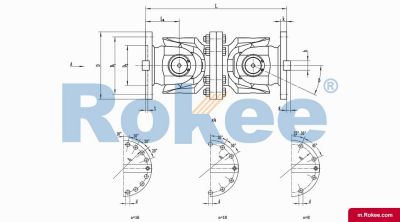

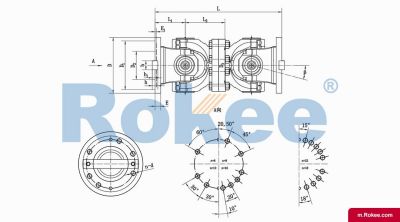

SWC-WD Cardan Shaft

SWC-WD non-telescopic short universal joint couplingView More -

SWC-WH Cardan Shaft

SWC-WH non-telescopic welded universal joint couplingView More -

SWP-A Cardan Shaft

SWP-A telescopic long type universal joint couplingView More -

SWP-B Cardan Shaft

SWP-B telescopic short type universal joint couplingView More -

SWP-C Cardan Shaft

SWP-C non telescopic short type universal joint couplingView More -

SWP-D Cardan Shaft

SWP-D non telescopic long type universal joint couplingView More

Universal Shaft is a mechanical coupling that can achieve angular and positional flexibility. It is mainly used to connect two shafts that must rotate synchronously but have angular deviation. Through its unique structure, it can reliably transmit torque and motion. There are various structural types of Universal Shafts to meet the needs of different application scenarios. Among them, the commonly used is the cross axis Universal Shaft, followed by the ball cage Universal Shaft. The angle between the two axes of Universal Shafts with different structural types is generally between 5 ° and 45 °. In addition, according to the magnitude of the transmitted torque, Universal Shafts can be classified into different types such as heavy, medium, light, and small.

The working principle of a Universal Shaft mainly depends on its internal cross axis or ball cage structure. When there is an angle deviation between the two shafts, the Universal Shaft can utilize the characteristics of these structures to achieve continuous rotation of the two shafts without being on the same axis, and reliably transmit torque and motion. This characteristic makes the Universal Shaft highly flexible and adaptable in mechanical transmission.

Universal Shafts are widely used in various mechanical and transportation systems due to their versatility and adaptability. For example, in the automotive industry, Universal Shafts are used to connect the transmission shaft between the engine and gearbox, as well as the connection between the drive axle and the half shaft; In mechanical equipment, Universal Shafts are often used to connect rotating components in different parts to achieve power transmission and synchronization of motion. In addition, Universal Shafts also have important applications in fields such as ships, aviation, and aerospace.

In order to ensure the normal operation and prolong the service life of the Universal Shaft, regular maintenance and upkeep are necessary. This includes checking the wear, lubrication, and fastening of the Universal Shaft. Once abnormalities or damages are found, they should be replaced or repaired in a timely manner.

In the complex network of mechanical power transmission systems, the universal shaft stands as a critical component that enables seamless torque and motion transfer between non-coaxial shafts. Its unique ability to accommodate angular misalignment, absorb shock loads, and maintain stable operation under varying conditions makes it indispensable across a wide spectrum of industries, from heavy metallurgy and shipbuilding to precision automotive and papermaking. Unlike rigid connectors that require strict coaxial alignment, the universal shaft introduces flexibility into power transmission, allowing machinery to operate efficiently even in dynamic and challenging environments.

At the core of a universal shaft's functionality lies its sophisticated structural design, which typically consists of universal joints, cross assemblies, yokes, and a central shaft body. The universal joint, often referred to as a Cardan joint in recognition of its historical development, is the key element that enables angular movement. A standard cross-type universal joint comprises a cross shaft with four cylindrical journals, each fitted with needle bearings and enclosed within yoke ends. The yokes are connected to the input and output shafts, while the cross shaft acts as the pivot point that allows the yokes to rotate relative to each other at varying angles. This design ensures that rotational motion is transmitted smoothly even when the two connected shafts are not aligned along the same axis. In addition to the basic cross-type design, there are also more advanced configurations such as the constant velocity (CV) joint, which incorporates ball bearings and a cage structure to eliminate the fluctuation in angular velocity that can occur in simple cross-type joints, making it particularly suitable for high-speed and precision applications.

The central shaft body, which connects the two universal joints, plays a crucial role in transmitting torque and accommodating axial movement. Depending on the application requirements, the shaft body can be designed as a solid shaft or a hollow shaft. Hollow shafts are often preferred in situations where weight reduction is critical, such as in automotive and aerospace applications, as they offer a higher strength-to-weight ratio compared to solid shafts of the same material and diameter. Some advanced designs also incorporate telescopic sections, such as involute spline connections, which allow for axial length compensation to accommodate thermal expansion and contraction of the shaft during operation or positional changes of the connected machinery. The integration of these structural elements ensures that the universal shaft can adapt to various misalignment conditions, including angular misalignment, axial displacement, and radial offset, while maintaining efficient power transmission.

The working principle of the universal shaft revolves around the ability of the universal joints to transfer rotational motion between non-coaxial shafts. When the input shaft rotates, it drives the connected yoke, which in turn rotates the cross shaft. The cross shaft then transmits this rotational motion to the opposite yoke, which drives the output shaft. The needle bearings mounted on the cross shaft journals minimize friction during this process, ensuring smooth rotation and reducing wear. In a simple single universal joint, the angular velocity of the output shaft fluctuates slightly as the joint rotates, especially at large deflection angles. This fluctuation, known as angular velocity variation, can cause vibration and noise in the transmission system. To mitigate this issue, most practical applications use a double universal joint configuration, where two universal joints are mounted at both ends of the central shaft and aligned in a specific manner. This arrangement ensures that the angular velocity fluctuations from the first joint are canceled out by the second joint, resulting in constant velocity transmission between the input and output shafts.

Material selection is a critical factor that directly impacts the performance, durability, and service life of a universal shaft. The choice of materials depends on various factors, including the torque requirements, operating speed, environmental conditions (such as temperature, humidity, and corrosive agents), and weight constraints. For the core components such as the cross shaft and yokes, high-strength alloy steels are commonly used due to their excellent mechanical properties. 42CrMo alloy steel, in particular, is a popular choice for cross shafts as it offers high tensile strength, good toughness, and excellent wear resistance when subjected to quenching and tempering heat treatment. Other commonly used alloys include 40Cr and 20CrMnTi, which are also subjected to heat treatment processes such as carburizing to enhance surface hardness and wear resistance.

The yoke components, which bear significant torsional and bending loads, are typically made from 45# carbon steel or 35CrMo alloy steel. For light-load applications, cast iron may be used as a cost-effective alternative, although it has lower strength and fatigue resistance compared to steel. The bearing components, such as needle bearings, are usually made from high-carbon chromium bearing steel, which provides excellent hardness and wear resistance. In specialized environments, the material selection must be adjusted accordingly. For example, in marine or chemical applications where corrosion resistance is critical, stainless steel (such as 304 or 316) or carbon steel with nickel-plated or galvanized surfaces is used. In high-temperature environments, such as in metallurgical rolling mills, heat-resistant alloys like 35CrMo are employed, often with additional high-temperature coatings to further enhance heat resistance. For applications requiring lightweight design, such as in automotive and aerospace, aluminum alloys or titanium alloys may be used for certain components, although this often involves a trade-off in terms of strength.

The manufacturing process of universal shafts also plays a vital role in ensuring their performance and reliability. The cross shaft and yokes are typically produced using forging processes, such as free forging or die forging, which help eliminate internal defects in the material, improve material density, and enhance mechanical properties. Forging is followed by precision machining processes, including turning, milling, and drilling, to achieve the required dimensional accuracy and surface finish. The heat treatment of the core components is a critical step that must be carefully controlled to ensure the desired material properties. Quenching and tempering are commonly used to achieve a balance between strength and toughness, while carburizing is used to enhance the surface hardness of components subject to high wear.

The assembly process of universal shafts requires strict quality control to ensure proper alignment and fit of the components. The needle bearings must be correctly installed in the yoke bores, and the cross shaft must rotate freely without jamming. The central shaft is connected to the yokes using various methods, including welding, bolted connections, or spline fits. For welded connections, processes such as automatic CO2 gas shielded welding or friction welding are used to ensure strong, reliable joints with minimal internal stress. After assembly, the universal shaft undergoes dynamic balance testing to eliminate any unbalanced masses that could cause vibration during operation. Balance weights or balance plates are welded to the shaft if necessary to ensure that the unbalance amount is within the allowable range, typically less than 100 g·cm for most applications.

Universal shafts find applications in a wide range of industries, each with specific requirements and operating conditions. In the metallurgical industry, they are essential components in rolling mills, piercing machines, and straightening machines, where they need to transmit extremely high torques (often exceeding 20,000 kNm) under harsh conditions involving high temperatures, heavy loads, and significant misalignment. The large universal shafts used in rolling mills can weigh over 50 tons and have a diameter of more than 1.3 meters, demonstrating the robustness of their design. In the mining industry, universal shafts are used in conveyors, crushers, and mining trucks, where they must withstand shock loads and operate reliably in dusty, corrosive environments.

The automotive industry is another major user of universal shafts, where they are used as drive shafts to transmit torque from the engine to the wheels. In rear-wheel-drive and four-wheel-drive vehicles, the drive shaft connects the transmission to the differential, accommodating the relative movement between the vehicle's chassis and the wheels. The use of CV joints in modern automotive drive shafts ensures smooth power transmission even at large steering angles, improving vehicle handling and reducing vibration. In the shipbuilding industry, universal shafts are used in marine propulsion systems to connect the engine to the propeller, adapting to the pitch and roll movements of the ship during navigation. They must be corrosion-resistant to withstand the harsh marine environment and capable of transmitting high torques to drive the ship's propellers efficiently.

The papermaking industry also relies heavily on universal shafts in paper machines and presses. These applications require precise and smooth power transmission to ensure consistent paper quality, and the universal shafts must operate at high speeds with minimal vibration. Other industries that use universal shafts include the construction machinery industry (in excavators, loaders, and bulldozers), the cement industry (in rotary kilns), the sugar industry (in processing machinery), and the aerospace industry (in aircraft engine systems). The versatility of the universal shaft makes it a critical component in almost all sectors of heavy industry and manufacturing.

Proper maintenance is essential to ensure the reliable operation and extend the service life of universal shafts. Regular maintenance practices include inspection, lubrication, and replacement of worn components. Periodic inspection should check for signs of wear, such as excessive play in the universal joints, damage to the needle bearings, and bending or deformation of the central shaft. The connection bolts and fasteners should be checked for tightness, as loose bolts can cause vibration and lead to component failure. Lubrication is a particularly important maintenance task, as it reduces friction between moving parts and prevents corrosion. The type of lubricant used depends on the operating temperature; for example, No. 3 lithium-based grease is suitable for summer use, while No. 2 lithium-based grease is used in winter. The lubrication points should be greased regularly to ensure that the bearings and other moving parts are adequately lubricated.

When faults occur in a universal shaft, timely diagnosis and repair are crucial to avoid further damage to the transmission system and associated machinery. Common faults include abnormal noise, vibration, and reduced transmission efficiency. Abnormal noise, such as a "clunking" sound during startup or acceleration, is often indicative of loose connections or worn universal joint bearings. A continuous "hum" or "whirring" sound that increases with speed may be caused by worn intermediate bearings or imbalance in the central shaft. Vibration in the transmission system can be caused by a bent shaft, lost balance weights, or incorrect alignment of the universal joints.

Traditional repair methods for worn universal shaft components include welding, bushing installation, and metal spraying. However, these methods can introduce internal stresses into the components, which may lead to cracking or failure under heavy loads. Modern repair techniques, such as the use of polymer composite materials, offer a more effective and cost-efficient alternative. These materials can be applied on-site, reducing downtime, and provide excellent adhesion, wear resistance, and impact absorption properties. They can also be machined to the exact dimensions required, ensuring a precise fit and restoring the component's original performance. For severely damaged components, such as bent shafts or cracked yokes, replacement is often the safest and most reliable option.

The future development of universal shafts is driven by the increasing demand for higher performance, greater efficiency, and improved reliability in industrial applications. One of the key trends is the adoption of advanced materials and manufacturing technologies to reduce weight while increasing torque capacity. The use of carbon fiber-reinforced polymer (CFRP) in the central shaft is an emerging trend, as this material offers significantly higher strength-to-weight ratios compared to traditional steel, reducing the overall weight of the shaft and improving energy efficiency. Another trend is the integration of smart monitoring technologies, such as sensors embedded in the universal shaft components, to real-time monitor parameters such as temperature, vibration, and load. This allows for predictive maintenance, where potential faults can be detected early before they lead to component failure, reducing downtime and maintenance costs.

In addition, there is a growing focus on optimizing the design of universal shafts using advanced simulation tools, such as finite element analysis (FEA). These tools allow engineers to simulate the performance of the shaft under various operating conditions, identify potential stress concentrations, and optimize the design to improve strength and durability. The development of more efficient and compact universal joint designs is also ongoing, with a focus on reducing friction and improving power transmission efficiency. For example, the use of self-lubricating bearings reduces the need for regular lubrication, making the universal shaft more suitable for applications where maintenance access is limited.

In conclusion, the universal shaft is a vital component in mechanical power transmission systems, enabling the efficient and reliable transfer of torque between non-coaxial shafts. Its structural design, material selection, and manufacturing processes are tailored to meet the specific requirements of various industrial applications, from heavy metallurgy and mining to precision automotive and aerospace. Proper maintenance and timely repair are essential to ensure its long service life and optimal performance. As industrial technology continues to advance, the universal shaft is evolving to become lighter, stronger, more efficient, and more intelligent, with the integration of advanced materials and smart monitoring technologies. The ongoing development of this essential component will continue to play a crucial role in driving the efficiency and productivity of industrial machinery across the globe.

« Universal Shafts » Update Date: 2026/1/10