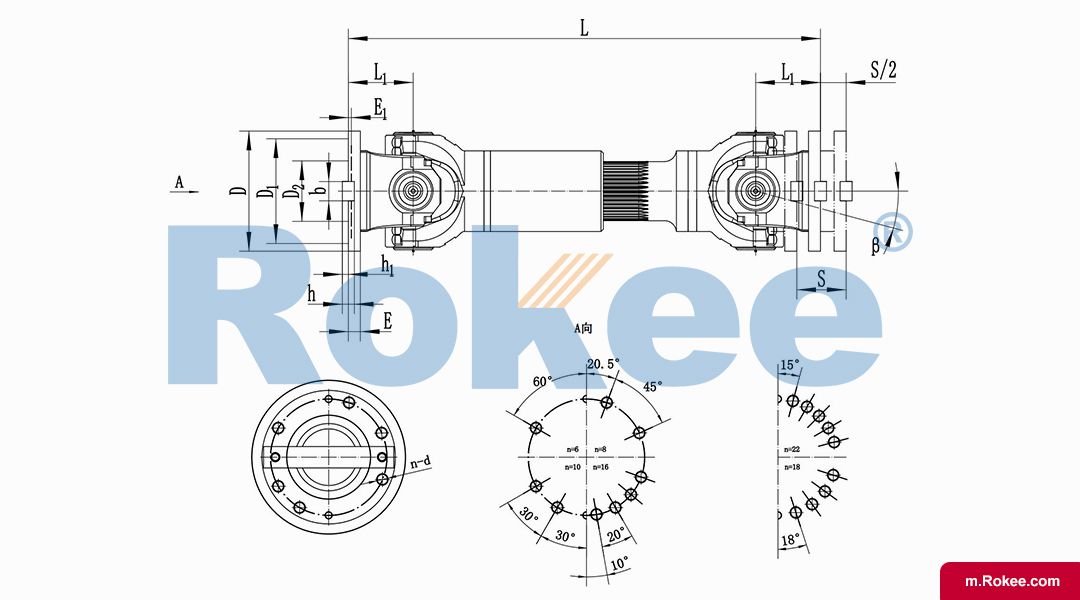

SWP-B telescopic short type universal joint coupling

| Model | Rotary Diameter D mm | Nominal Torque Tn kN ·m | Pulsating Fatigue Torque Tp kN ·m | Alternating Fatigue Torque Tf kN ·m | Axis Angle β(°) | Expansion Amount S mm | Size / mm | Rotational Inertia kg ·m2 | Quality kg | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lmin | D1 | D2 (H7) | E | E1 | bxh | h1 | L1 | Nxd | Lmin | Increase | Lmin mm | Increase 100mm | |||||||

| mm | 100mm | ||||||||||||||||||

| SWP160B | 160 | 20 | 14 | 10 | ≤15 | 50 | 575 | 140 | 95 | 15 | 4 | 20×12 | 6 | 90 | 6×φ12 | 0.148 | 0.004 | 46 | 3.92 |

| SWP180B | 180 | 28 | 20 | 14 | ≤15 | 60 | 650 | 155 | 105 | 15 | 4 | 24×14 | 7 | 105 | 6xφ15 | 0.268 | 0.005 | 66 | 4.75 |

| SWP200B | 200 | 40 | 28 | 20 | ≤15 | 70 | 735 | 175 | 125 | 17 | 5 | 28×16 | 8 | 120 | 8xφ15 | 0.430 | 0.009 | 86 | 6.46 |

| SWP225B | 225 | 56 | 40 | 28 | ≤15 | 76 | 850 | 196 | 135 | 20 | 5 | 32×18 | 9 | 145 | 8xφ17 | 0.826 | 0.013 | 129 | 8.05 |

| SWP250B | 250 | 80 | 56 | 40 | ≤15 | 80 | 920 | 218 | 150 | 25 | 5 | 40×25 | 12.5 | 165 | 8xφ19 | 1.553 | 0.026 | 199 | 12.54 |

| SWP285B | 285 | 112 | 78 | 56 | ≤15 | 100 | 1070 | 245 | 170 | 27 | 7 | 40×30 | 15 | 180 | 8×φ21 | 2.856 | 0.043 | 280 | 15.18 |

| SWP315B | 315 | 160 | 112 | 80 | ≤15 | 110 | 1200 | 280 | 185 | 32 | 7 | 40×30 | 15 | 205 | 10xφ23 | 4.774 | 0.078 | 385 | 19.25 |

| SWP350B | 350 | 224 | 157 | 112 | ≤15 | 120 | 1330 | 310 | 210 | 35 | 8 | 50×32 | 16 | 225 | 10xφ23 | 7.788 | 0.097 | 509 | 22.75 |

| SWP390B | 390 | 315 | 220 | 158 | ≤10 | 120 | 1290 | 345 | 235 | 40 | 8 | 70×36 | 18 | 215 | 10×φ25 | 11.628 | 0.122 | 612 | 25.62 |

| SWP435B | 435 | 450 | 315 | 225 | ≤10 | 150 | 1520 | 385 | 255 | 4.2 | 10 | 80×40 | 20 | 245 | 16xφ28 | 22.032 | 0.176 | 918 | 29.12 |

| SWP480B | 480 | 630 | 440 | 315 | ≤10 | 180 | 1690 | 425 | 275 | 47 | 12 | 95×45 | 22.5 | 275 | 16xφ31 | 35.482 | 0.238 | 1232 | 35.86 |

| SWP550B | 550 | 900 | 630 | 450 | ≤10 | 190 | 1850 | 492 | 320 | 50 | 12 | 100×45 | 22.5 | 305 | 16xφ31 | 67.868 | 0.341 | 1786 | 40.33 |

| SWP600B | 600 | 1250 | 875 | 625 | ≤10 | 210 | 2480 | 544 | 380 | 55 | 15 | 90×55 | 27.5 | 370 | 22xφ34 | 137.115 | 0.467 | 3047 | 47.65 |

| SWP650B | 650 | 1600 | 1120 | 800 | ≤10 | 230 | 2580 | 585 | 390 | 60 | 15 | 100×60 | 30 | 405 | 18xφ38 | 194.991 | 0.623 | 3693 | 54.48 |

SWP-B Cardan Shaft is a cross axis universal coupling with telescopic short function, widely used in various transmission systems.

The SWP-B Cardan Shaft is mainly composed of two half couplings, a cross shaft, a bearing seat, an expansion sleeve, and other components. Among them, the cross shaft is the core component of the coupling, which is connected to the half coupling through bearings to achieve angle compensation and torque transmission between the two shafts. The expansion sleeve is used to adjust the axial clearance between the two shafts, ensuring the stability and reliability of the coupling during operation.

Main Features

Strong angle compensation capability: SWP-B universal Shaft has a large angle compensation range and can adapt to angle changes under various complex working conditions.

Strong load-bearing capacity: The coupling adopts high-strength materials and high-quality bearings, which have high load-bearing capacity and fatigue resistance.

Convenient telescopic adjustment: Through the design of the telescopic sleeve, the axial clearance between the two shafts can be easily adjusted to meet the needs of different working conditions.

Smooth operation: The coupling has low noise and vibration during operation, ensuring the stability and reliability of the transmission system.

SWP-B universal coupling has a variety of models and specifications to meet the needs of different transmission systems. Its main parameters include model, expansion and contraction, size, moment of inertia, mass, etc. For example, models such as SWP160B, SWP180B, SWP220A, etc., each have specific expansion and size parameters.

Installation and Maintenance

Installation: When installing the SWP-B universal coupling, it is necessary to ensure that the flange joint surface is clean and smooth, and avoid adverse factors such as reducing the friction force of the contact surface or reducing the contact area of the joint surface. At the same time, the flange connection bolts should be tightened according to the prescribed tightening torque to ensure the stability and reliability of the coupling.

Maintenance: During the operation of the coupling, the flange connection bolts should be regularly checked for looseness and tightened in a timely manner. At the same time, the joint bearings and spline joints should be regularly lubricated to ensure the normal operation of the coupling. Under high temperature working conditions, grease should be added every 1-2 weeks; Under normal working conditions, grease should be added once every 500 hours of continuous work; Under intermittent working conditions, grease should be added every three months.

SWP-B universal couplings are widely used in various transmission systems, such as metallurgy, mining, machinery, chemical and other industries. Especially in transmission systems that require angle compensation and axial adjustment, SWP-B universal couplings have significant advantages.

SWP-B Cardan Shaft is a transmission component with excellent performance and wide application prospects. When selecting and using, reasonable selection and maintenance should be carried out according to specific working conditions and requirements.

URL: https://m.rokee.com/swp-cardan-shaft-couplings/swp-b-cardan-shaft.html