SWC-BH standard telescopic welded universal joint coupling

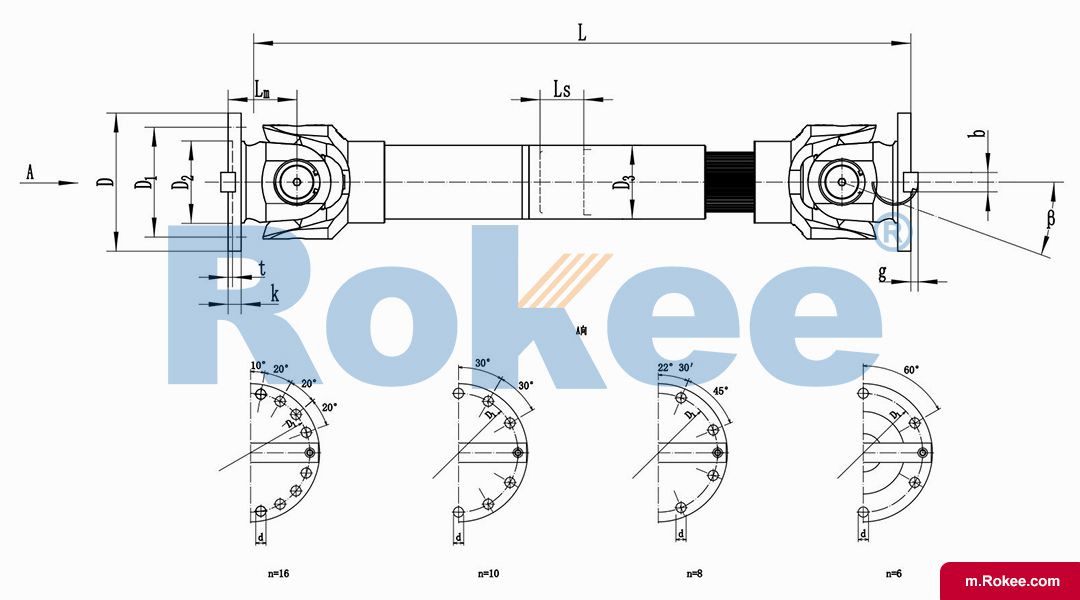

| Model | Rotary Diameter D/ mm | Nominal Torque Tn KN ·m | Fatigue Torque Tf KN ·m | Bearing Life Coefficient KL | Axis Angle β (°) | Expansion Amount Ls mm | Size / mm | Rotational Inertia (kg ·m²) | Quality kg | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lmin | D1 (js11) | D2 (H7) | D3 | Lm | n×φd | k | t | b (h9) | g | Lmin mm | Increase 100mm | Lmin mm | Increase 100mm | |||||||

| SWC100BH | 100 | 2.5 | 1.25 | 5.795×10-4 | ≤25 | 55 | 405 | 84 | 57 | 60 | 55 | 6×φ9 | 7 | 2.5 | 一 | 一 | 0.004 | 0.0002 | 6.1 | 0.35 |

| SWC120BH | 120 | 5 | 2.5 | 4.641×10-3 | ≤25 | 80 | 485 | 102 | 75 | 70 | 65 | 8×φ11 | 8 | 2.5 | 一 | 一 | 0.011 | 0.0004 | 10.8 | 0.55 |

| SWC150BH | 150 | 10 | 5 | 0.51×10-1 | ≤25 | 80 | 590 | 130 | 90 | 89 | 80 | 8×φ13 | 10 | 3 | 一 | 一 | 0.042 | 0.001 | 24.5 | 0.85 |

| SWC180BH | 180 | 22.4 | 11.2 | 0.245 | ≤15 | 100 | 840 | 155 | 105 | 114 | 110 | 8×φ17 | 17 | 5 | 24 | 7 | 0.175 | 0.007 | 70 | 2.8 |

| SWC200BH | 200 | 36 | 18 | 1.115 | ≤15 | 110 | 860 | 170 | 120 | 133 | 115 | 8×φ17 | 17 | 5 | 28 | 8 | 0.314 | 0.013 | 98 | 3.7 |

| SWC225BH | 225 | 56 | 28 | 7.812 | ≤15 | 140 | 920 | 196 | 135 | 152 | 120 | 8×φ17 | 20 | 5 | 32 | 9 | 0.538 | 0.023 | 122 | 4.9 |

| SWC250BH | 250 | 80 | 40 | 2.82×101 | ≤15 | 140 | 1035 | 218 | 150 | 168 | 140 | 8×φ19 | 25 | 6 | 40 | 12.5 | 0.966 | 0.028 | 172 | 5.3 |

| SWC285BH | 285 | 120 | 58 | 8.28×101 | ≤15 | 140 | 1190 | 245 | 170 | 194 | 160 | 8×φ21 | 27 | 7 | 40 | 15 | 2.011 | 0.051 | 263 | 6.3 |

| SWC315BH | 315 | 160 | 80 | 2.79×102 | ≤15 | 140 | 1315 | 280 | 185 | 219 | 180 | 10×φ23 | 32 | 8 | 40 | 15 | 3.605 | 0.08 | 382 | 8 |

| SWC350BH | 350 | 225 | 110 | 7.44×102 | ≤15 | 150 | 1440 | 310 | 210 | 245 | 194 | 10×φ23 | 35 | 8 | 50 | 16 | 5.316 | 0.146 | 532 | 11.5 |

| SWC390BH | 390 | 320 | 160 | 1.86×103 | ≤15 | 170 | 1590 | 345 | 235 | 267 | 215 | 10×φ25 | 40 | 8 | 70 | 18 | 12.16 | 0.222 | 738 | 15 |

| SWC440BH | 440 | 500 | 250 | 8.25×103 | ≤15 | 190 | 1875 | 390 | 255 | 325 | 260 | 16×φ28 | 42 | 10 | 80 | 20 | 21.42 | 0.474 | 1190 | 21.7 |

| SWC490BH | 490 | 700 | 350 | 2.154×104 | ≤15 | 190 | 1985 | 435 | 275 | 351 | 270 | 16×φ31 | 47 | 12 | 90 | 22.5 | 34.10 | 0.690 | 1542 | 27.3 |

| SWC550BH | 550 | 1000 | 500 | 6.335×104 | ≤15 | 240 | 2300 | 492 | 320 | 426 | 305 | 16×φ31 | 50 | 12 | 100 | 22.5 | 68.92 | 1.357 | 2380 | 34 |

SWC-BH Cardan Shaft, also known as SWC-BH standard telescopic welded cross shaft universal coupling, is a widely used tool for transmitting torque in mechanical shaft systems of multiple heavy machinery industries.

SWC-BH Cardan Shaft is widely used in metallurgy, lifting, engineering transportation, mining, petroleum, shipbuilding, coal, rubber, papermaking machinery and other heavy machinery industries.

Main Features

Strong angle compensation capability: The SWC type axis can have a bending angle of 15 °~25 °, and the SWP type can reach about 10 °, which can adapt to the displacement generated by shaft transmission under different working conditions.

Compact and reasonable structure: Adopting an integral fork design improves the reliability of transportation, while making the structure more compact, easy to install and maintain.

Large bearing capacity: Compared with other types of couplings with the same rotational diameter, SWC-BH universal couplings transmit greater torque, making them particularly suitable for mechanical equipment with limited rotational diameter.

High transmission efficiency: The transmission efficiency is as high as 98%~99.8%, which has a significant energy-saving effect when used for high-power transmission and can reduce power consumption.

Smooth transportation and low noise: The general noise level is 30-40 dB (A), ensuring a comfortable working environment.

Easy installation, disassembly, and maintenance: The design of the bolt free structure avoids malignant damage caused by loose or broken bolts, extending its service life.

The SWC-BH Cardan Shaft has multiple models, each with corresponding detailed parameters such as rotation diameter, nominal torque, fatigue torque, expansion and contraction, axis angle, and size.

SWC-BH universal couplings typically use high-quality alloy steel materials, such as 35CrMo alloy steel quenched and tempered, to ensure their durability and excellent performance. The cross axis part is made of 20CRMNTI material and has undergone strict inspection and multi row needle rolling design to improve wear resistance and strength requirements. During the processing, the equipment and personnel required for each step are all completed in our factory, greatly saving costs, controlling quality, and being able to quickly respond to customer delivery requirements.

Due to the many advantages mentioned above, SWC-BH universal couplings have broad application prospects in the heavy machinery industry. With the continuous development of industrial technology, the requirements for transmission equipment are also increasing. The SWC-BH Cardan Shaft, with its high efficiency, reliability, and durability, will undoubtedly occupy a more important position in the future market.

SWC-BH Cardan Shaft is a high-performance and widely used transmission equipment. When selecting and using, reasonable selection should be made based on specific operating conditions and equipment requirements to ensure optimal performance and service life.

URL: https://m.rokee.com/swc-cardan-shaft-couplings/swc-bh-cardan-shaft.html