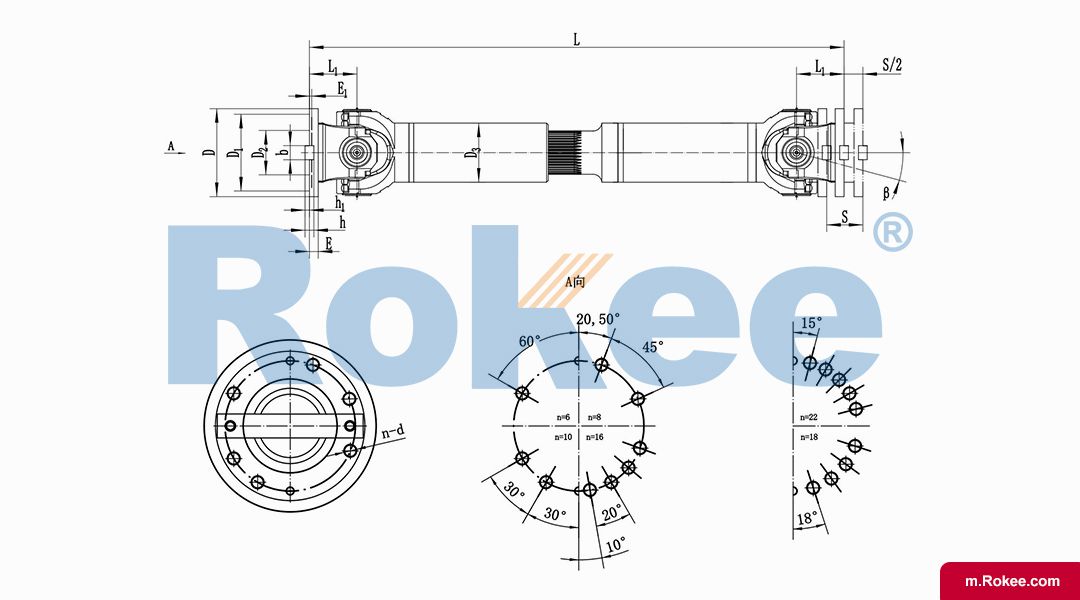

SWP-A telescopic long type universal joint coupling

| Model | Rotary Diameter D mm | Nominal Torque Tn kN ·m | Pulsating Fatigue Torque Tp kN ·m | Alternating Fatigue Torque Tf kN ·m | Axis Angle β(°) | Expansion Amount s mm | Size / mm | Rotational Inertia kg ·m2 | Quality kg | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lmin | D1 | D2 (H7) | D3 | E | E1 | bxh | h1 | L1 | Nxd | Lmin mm | Increase 100mm | Lmin mm | Increase 100mm | |||||||

| SWP160A | 160 | 20 | 14 | 10 | ≤15 | 50 | 655 | 140 | 95 | 121 | 15 | 4 | 20×12 | 6 | 90 | 6xφ13 | 0.167 | 0.008 | 52 | 2.5 |

| SWP180A | 180 | 28 | 20 | 14 | ≤15 | 60 | 760 | 155 | 105 | 127 | 15 | 4 | 24×14 | 7 | 105 | 6xφ15 | 0.304 | 0.012 | 75 | 3.4 |

| SWP200A | 200 | 40 | 28 | 20 | ≤15 | 70 | 825 | 175 | 125 | 140 | 17 | 5 | 28×16 | 8 | 120 | 8×φ15 | 0.490 | 0.016 | 98 | 3.8 |

| SWP225A | 225 | 56 | 40 | 28 | ≤15 | 80 | 950 | 196 | 135 | 168 | 20 | 5 | 32×18 | 9 | 145 | 8xφ17 | 0.916 | 0.039 | 143 | 6.2 |

| SWP250A | 250 | 80 | 56 | 40 | ≤15 | 90 | 1055 | 218 | 150 | 219 | 25 | 5 | 40×25 | 12.5 | 165 | 8xφ19 | 1.763 | 0.079 | 226 | 7.2 |

| SWP285A | 285 | 112 | 78 | 56 | ≤15 | 100 | 1200 | 245 | 170 | 219 | 27 | 7 | 40×30 | 15 | 180 | 8xφ21 | 3.193 | 0.099 | 313 | 9.4 |

| SWP315A | 315 | 160 | 112 | 80 | ≤15 | 110 | 1330 | 280 | 185 | 273 | 32 | 7 | 40×30 | 15 | 205 | 10×φ23 | 5.270 | 0.219 | 425 | 12.8 |

| SWP350A | 350 | 224 | 157 | 112 | ≤15 | 120 | 1480 | 310 | 210 | 273 | 35 | 8 | 50×32 | 16 | 225 | 10×φ23 | 8.645 | 0.226 | 565 | 13.9 |

| SWP390A | 390 | 315 | 220 | 158 | ≤10 | 120 | 1480 | 345 | 235 | 273 | 40 | 8 | 70×36 | 18 | 215 | 10×φ25 | 12.920 | 0.303 | 680 | 21.1 |

| SWP435A | 435 | 450 | 315 | 225 | ≤10 | 150 | 1670 | 385 | 255 | 325 | 42 | 10 | 80×40 | 20 | 245 | 16×φ28 | 24.240 | 0.545 | 1010 | 25.7 |

| SWP480A | 480 | 630 | 440 | 315 | ≤10 | 170 | 1860 | 425 | 275 | 351 | 47 | 12 | 90×45 | 22.5 | 275 | 16×φ31 | 38.736 | 0.755 | 1345 | 30.7 |

| SWP550A | 550 | 900 | 630 | 450 | ≤10 | 190 | 2100 | 492 | 320 | 426 | 50 | 12 | 100×45 | 22.5 | 305 | 16×φ31 | 76.570 | 1.435 | 2015 | 38.1 |

| SWP600A | 600 | 1250 | 875 | 625 | ≤10 | 210 | 2520 | 544 | 380 | 480 | 55 | 15 | 90×55 | 27.5 | 370 | 22xφ34 | 134.100 | 2.493 | 2980 | 53.2 |

| SWP650A | 650 | 1600 | 1120 | 800 | ≤10 | 230 | 2630 | 585 | 390 | 500 | 60 | 15 | 100×60 | 30 | 405 | 18×φ38 | 192.720 | 3.210 | 3650 | 65.1 |

SWP-A type Cardan Shaft belongs to a type of cross axis Cardan Shaft with split bearing seat. Its design feature is that the bearing seat is split and fixed by shaft bolts. This structure facilitates the replacement of bearings and improves the maintainability of the equipment.

SWP-A Cardan Shaft is widely used in rolling machinery, lifting and transportation machinery, and other heavy machinery, mainly used to connect transmission shafts with two different axes. Its rotation diameter range is between 160mm and 640mm, and the nominal torque range is between 16kn · m and 1250kn · m, which can meet the needs of different mechanical equipment.

The main dimensions and parameters of SWP-A universal Shaft include model, expansion and contraction, dimensions (such as Lmin, D3, etc.), rotational penetration, and mass. Different models of SWP-A universal couplings have different parameter values, such as SWP160A, SWP180A, SWP200A, etc. Their expansion, size, and mass parameters are all different. Therefore, when choosing SWP-A Cardan Shaft, it is necessary to match it according to specific usage requirements and mechanical equipment parameters.

Performance Characteristics

Strong bearing capacity: SWP-A universal coupling can withstand large torque and axial force, suitable for transmission systems of heavy machinery and equipment.

Angle compensation capability: This coupling has a certain axis angle compensation capability, which can adapt to the axis deviation generated by mechanical equipment during operation.

Easy to maintain: Due to the split design of the bearing seat, there is no need to disassemble the entire coupling when replacing the bearing, reducing maintenance costs and difficulty.

Strong adaptability: SWP-A Cardan Shaft is suitable for various working environments and transmission systems, with high universality and adaptability.

Precautions

When installing the SWP-A Cardan Shaft, it should be ensured that the axes of the two half couplings are on the same plane and consistent with the axis of the main engine.

During use, the wear of the coupling should be regularly checked, and severely worn components should be replaced in a timely manner.

Avoid using under conditions that exceed the rated torque and axial force of the coupling, in order to avoid damaging the coupling or affecting the normal operation of mechanical equipment.

SWP-A Cardan Shaft is a high-performance and structurally sound transmission component with broad application prospects in heavy machinery and equipment.

URL: https://m.rokee.com/swp-cardan-shaft-couplings/swp-a-cardan-shaft.html