SWC-DH short telescopic welded universal joint coupling

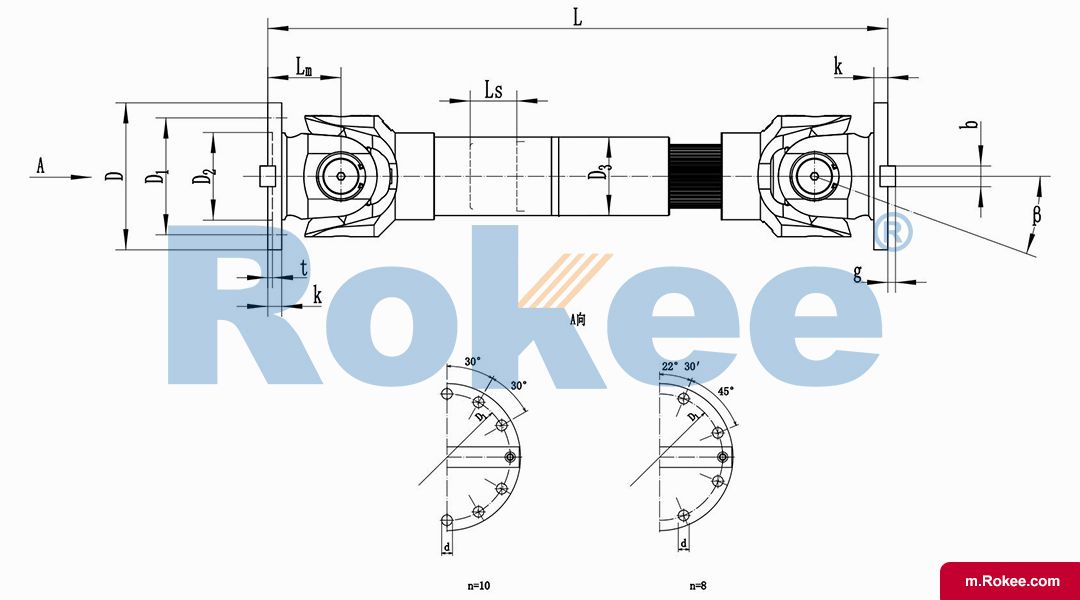

| Model | Rotary Diameter D mm | Nominal Torque Tn KN ·m | Fatigue Torque Tf KN ·m | Bearing Life Coefficient KL | Axis Angle β (°) | Expansion Amount Ls mm | Size/mm | Rotational Inertia (kg ·m²) | Quality kg | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lmin | D1 (js11) | D2 (H7) | D3 | Lm | n×φd | k | t | b (h9) | g | Lmin/ mm | Increase 100mm | Lmin mm | Increase 100mm | |||||||

| SWC180DH1 | 180 | 22.4 | 11.2 | 0.245 | ≤15 | 55 | 600 | 155 | 105 | 114 | 110 | 8×φ17 | 17 | 5 | 24 | 7 | 0.162 | 0.007 | 56 | 2.8 |

| SWC180DH2 | 105 | 650 | 0.165 | 58 | ||||||||||||||||

| SWC200DH1 | 200 | 36 | 18 | 1.115 | ≤15 | 50 | 620 | 170 | 120 | 133 | 115 | 8×φ17 | 17 | 5 | 38 | 8 | 0.261 | 0.013 | 74 | 3.7 |

| SWC200DH2 | 120 | 680 | 0.276 | 76 | ||||||||||||||||

| SWC225DH1 | 225 | 56 | 28 | 7.812 | ≤15 | 70 | 640 | 196 | 135 | 152 | 120 | 8xφ17 | 20 | 5 | 32 | 9 | 0.397 | 0.023 | 92 | 4.9 |

| SWC225DH2 | 140 | 710 | 0.415 | 95 | ||||||||||||||||

| SWC250DH1 | 250 | 80 | 40 | 2.82×101 | ≤15 | 70 | 735 | 218 | 150 | 168 | 140 | 8×φ19 | 25 | 5 | 40 | 12 | 0.885 | 0.028 | 136 | 5.3 |

| SWC250DH2 | 130 | 795 | 0.9 | 148 | ||||||||||||||||

| SWC285DH1 | 285 | 120 | 58 | 8.82×101 | ≤15 | 80 | 880 | 245 | 170 | 194 | 160 | 8×φ21 | 27 | 7 | 40 | 15 | 1.801 | 0.051 | 221 | 6.3 |

| SWC285DH2 | 150 | 950 | 1.876 | 229 | ||||||||||||||||

| SWC315DH1 | 315 | 160 | 80 | 2.79×102 | ≤15 | 90 | 980 | 280 | 185 | 219 | 180 | 10×φ23 | 32 | 8 | 40 | 15 | 3.163 | 0.080 | 334 | 8 |

| SWC315DH2 | 180 | 1070 | 3.331 | 346 | ||||||||||||||||

| SWC350DH1 | 350 | 225 | 110 | 7.44×102 | ≤15 | 90 | 1070 | 310 | 210 | 245 | 194 | 10×p23 | 35 | 8 | 50 | 16 | 5.330 | 0.146 | 452 | 11.5 |

| SWC350DH2 | 190 | 1170 | 5.721 | 475 | ||||||||||||||||

| SWC390DH1 | 390 | 320 | 160 | 1.86×103 | ≤15 | 90 | 1200 | 345 | 235 | 267 | 215 | 10×φ25 | 40 | 8 | 70 | 18 | 10.76 | 0.222 | 600 | 15 |

| SWC390DH2 | 190 | 1300 | l1.13 | 655 | ||||||||||||||||

SWC-DH Cardan Shaft, especially SWC-DH short telescopic welded universal coupling, is a commonly used type of joint, widely used in various industrial fields.

The SWC-DH Cardan Shaft is composed of two fork shaped parts and a cross shaped part, and has the characteristics of compact and reasonable design. It adopts an integral fork head, which enhances the reliability of the structure, avoids weak links that may be caused by bolt compression of the bearing seat (cover), and thus improves the service life.

Performance Advantages

Angle compensation capability: SWC-DH Cardan Shaft has a large angle compensation capability, and the axis angle can reach a certain range (such as 15 °~25 °), which can adapt to the angle changes between different axes.

Load bearing capacity: Compared with other types of couplings with the same rotation diameter, SWC-DH universal couplings transmit greater torque and have stronger load bearing capacity. This makes it more widely applicable in mechanical equipment with limited rotation diameter.

Transmission efficiency: Its transmission efficiency is as high as 98%~99.8%, which has a significant energy-saving effect in high-power transmission and can reduce power consumption.

Smooth transmission and low noise: The SWC-DH Cardan Shaft exhibits smoothness during the transmission process, with low noise levels, generally ranging from 30 to 40dB (A), providing a good working environment.

Easy installation, disassembly, and maintenance: Its structural design makes installation, disassembly, and maintenance relatively simple and fast.

SWC-DH universal couplings are widely used in mechanical shaft systems for metallurgy, lifting, engineering transportation, mining, petroleum, shipbuilding, coal, rubber, papermaking machinery, and other heavy machinery industries to transmit torque. Its high performance and reliability make it an indispensable transmission component in these fields.

When selecting SWC-DH universal couplings, it is necessary to comprehensively consider factors such as load characteristics, calculated torque, bearing life, and operating speed. At the same time, certain conditions should be ensured during the installation process, such as the equal angle between the intermediate shaft and the main and driven shafts, and the fork heads at both ends of the intermediate shaft being in the same phase, to ensure that the angular velocity of the driving shaft and the driven shaft is equal and achieve smooth transmission.

SWC-DH Cardan Shaft plays an important role in various industrial fields due to its unique structural characteristics and superior performance advantages. During the selection and installation process, actual needs and working conditions should be fully considered to ensure optimal performance and reliability.

URL: https://m.rokee.com/swc-cardan-shaft-couplings/swc-dh-cardan-shaft.html