Rokee is a chinese Universal Shaft Couplings Manufacturer, provide Universal Shaft Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Universal Shaft Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Universal Shaft Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

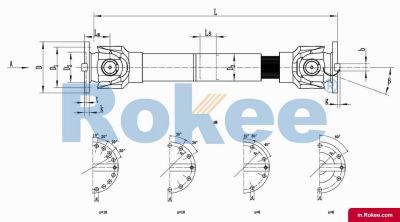

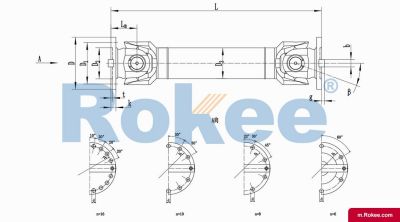

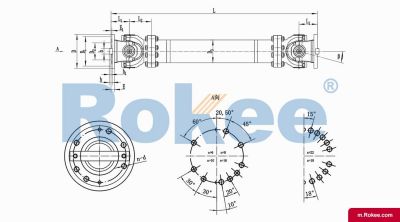

SWC-BH Cardan Shaft

SWC-BH standard telescopic welded universal joint couplingView More -

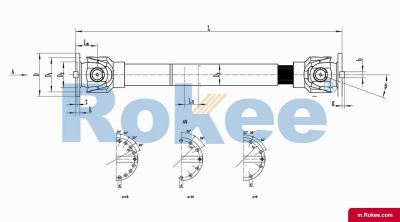

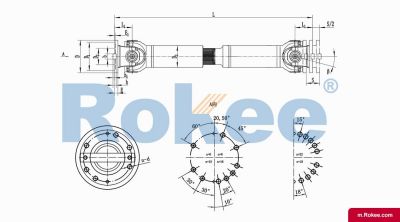

SWC-CH Cardan Shaft

SWC-CH long telescopic welded universal joint couplingView More -

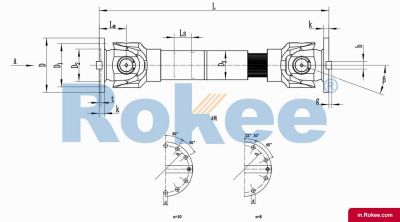

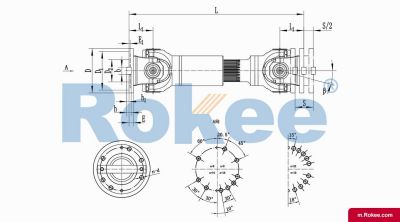

SWC-DH Cardan Shaft

SWC-DH short telescopic welded universal joint couplingView More -

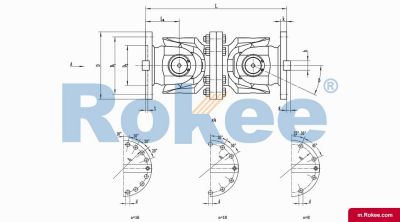

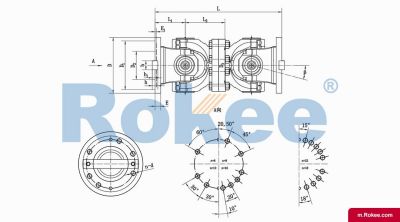

SWC-WD Cardan Shaft

SWC-WD non-telescopic short universal joint couplingView More -

SWC-WH Cardan Shaft

SWC-WH non-telescopic welded universal joint couplingView More -

SWP-A Cardan Shaft

SWP-A telescopic long type universal joint couplingView More -

SWP-B Cardan Shaft

SWP-B telescopic short type universal joint couplingView More -

SWP-C Cardan Shaft

SWP-C non telescopic short type universal joint couplingView More -

SWP-D Cardan Shaft

SWP-D non telescopic long type universal joint couplingView More

Universal Shaft Coupling is a mechanism that utilizes the characteristics of its mechanism to enable continuous rotation of the two shafts connected without being on the same axis and with an angle between the axes, and to reliably transmit torque and motion. It has a large angular compensation capability, compact structure, and high transmission efficiency. There are various structural types of Universal Shaft Couplings, such as cross shaft type, ball cage type, ball fork type, convex block type, ball pin type, ball joint type, ball joint plunger type, three pin type, trident rod type, three ball pin type, hinge rod type, etc. Among them, the most commonly used is the cross axis type, followed by the cage type. The core component of the cross axis Universal Shaft Coupling is the cross axis, which allows the two shafts to rotate continuously at equal angular velocities within a large range of angles. The ball cage Universal Shaft Coupling achieves two axis transmission through components such as the outer ring of the ball cage, the inner ring of the star shape, the cage, and the transmission steel ball. It is suitable for working conditions with large inclination angles and limited radial dimensions.

According to the magnitude of the transmitted torque, Universal Shaft Couplings can be classified as heavy, medium, light, and small. Different models of Universal Shaft Couplings are suitable for different mechanical transmission systems. Universal Shaft Couplings are widely used in metallurgy, heavy machinery, petrochemicals, engineering machinery, rail transportation, agricultural machinery, industrial machinery and other fields. For example, in steel rolling machinery, Universal Shaft Couplings are used to connect rollers and transmission systems, achieving reliable torque transmission; In heavy transportation equipment, it is used to connect the wheels and transmission shaft, ensuring that the vehicle can travel smoothly in various road conditions.

Universal Shaft Couplings have significant angular compensation capabilities and can adapt to changes in the angle between two shafts. Compact structure, small footprint, easy to install and maintain. The transmission efficiency of Universal Shaft Couplings is high, which can reduce energy loss and improve the overall performance of mechanical transmission systems. Using high-quality materials and advanced manufacturing processes, the Universal Shaft Coupling has high reliability and durability.

When selecting a Universal Shaft Coupling, factors such as the magnitude of the transmitted torque, the speed of the shaft, and the magnitude and direction of the relative displacement between the two shafts need to be considered. At the same time, it is necessary to refer to the characteristics of various types of couplings and choose a suitable type of coupling. For the Universal Shaft Couplings that have already been selected, regular maintenance and upkeep are required. For example, regular lubrication can extend its service life; When disassembling and reinstalling, it is necessary to pay attention to adjusting the position of the cross axis to balance wear and tear; In addition, it is necessary to regularly check the wear of the coupling and replace damaged components in a timely manner.

In the intricate network of mechanical power transmission systems, the universal shaft coupling stands as a pivotal component that bridges the gap between misaligned shafts, ensuring the seamless transfer of torque and rotational motion. Unlike rigid couplings that demand precise alignment between connected shafts, universal shaft couplings are engineered to accommodate angular, axial, and radial misalignments, making them indispensable in a wide range of industrial, automotive, aerospace, and marine applications. Their ability to adapt to dynamic operating conditions while maintaining transmission efficiency has solidified their position as a cornerstone of modern mechanical design, enabling the construction of more flexible, compact, and efficient machinery.

At the core of a universal shaft coupling's functionality lies its unique mechanical design, which allows for power transmission between two shafts that intersect at an angle. The basic operating principle revolves around the use of articulated joints that enable rotational motion to be transferred through varying angles without compromising torque delivery. The most common configuration consists of two yoke-shaped components (each attached to a respective shaft) connected by a central cross-shaped element, known as a spider or cross pin, which is supported by bearings at each of its four ends. This arrangement allows each yoke to rotate independently around the spider, accommodating angular misalignments between the shafts. When torque is applied to the input shaft, the rotational force is transmitted through the yoke to the spider, which then transfers it to the output yoke and subsequent shaft. The bearings within the yoke-spider interface reduce friction during articulation, ensuring smooth operation and minimizing wear. It is important to note that a single universal joint introduces a degree of speed fluctuation, where the output shaft speed varies slightly as the joint rotates through its cycle. This phenomenon, known as angular velocity variation, occurs because the effective radius of the yoke arms changes with the angle of misalignment. To mitigate this issue, engineers often employ double universal couplings, which consist of two single joints connected by an intermediate shaft. When properly aligned, the speed fluctuations from the first joint are canceled out by the second, resulting in constant velocity transmission—a critical feature for high-speed applications where smooth operation is paramount.

Universal shaft couplings exhibit a diverse range of structural designs, each tailored to specific application requirements such as load capacity, speed, misalignment tolerance, and environmental conditions. The three primary types are the cardan (cross-shaft) universal coupling, the constant velocity (CV) coupling, and the double universal coupling. The cardan coupling, named after the 16th-century mathematician Gerolamo Cardano, is the most basic and widely used type. It features a simple cross-shaped spider connecting two yokes, making it suitable for heavy-duty, low-to-medium speed applications such as industrial machinery, rolling mill, and agricultural equipment. Its robust construction allows it to handle high torque loads, but it is limited by the speed fluctuation issue inherent in single-joint designs, restricting its use in high-speed scenarios. The constant velocity coupling, by contrast, is engineered to eliminate speed fluctuations entirely. One of the most common CV coupling designs is the ball-and-cage type, which consists of a spherical outer race, a spherical inner race (connected to the shaft), and a cage containing steel balls that run in matching grooves on both races. The grooves are positioned such that the balls always lie in the plane perpendicular to the angle between the two shafts, ensuring that torque is transmitted at a constant velocity regardless of misalignment. This design makes CV couplings ideal for high-speed applications such as automotive drive shafts (particularly in front-wheel-drive vehicles), precision machine tools, and aerospace control systems. The double universal coupling, as mentioned earlier, addresses speed fluctuation by using two single joints in series with an intermediate shaft. This configuration not only provides constant velocity transmission but also allows for greater angular misalignment and longer distance between shafts, making it suitable for applications such as conveyor systems, marine propulsion, and large industrial turbines.

Material selection is a critical factor in determining the performance, durability, and reliability of universal shaft couplings, as it directly impacts load-bearing capacity, wear resistance, corrosion resistance, and overall lifespan. The choice of materials is primarily driven by the application's operating conditions, including torque requirements, rotational speed, temperature, and environmental factors such as humidity, chemicals, and abrasive particles. For the core components—yokes, spider, and shafts—high-strength alloys are the most common choice due to their excellent mechanical properties. Steel alloys such as 42CrMo, 40Cr, and 20CrMnTi are widely used for yokes and spiders, as they offer high tensile strength, fatigue resistance, and wear resistance when subjected to heat treatment processes such as quenching and tempering or carburizing. These heat treatments enhance the surface hardness of the components, making them capable of withstanding the high contact stresses and cyclic loads encountered during operation. For example, 20CrMnTi is often used for spider components due to its ability to achieve a hard surface (HRC 58-62) and tough core after carburizing, ensuring resistance to both wear and impact. Yokes, on the other hand, may be fabricated from 45号 steel or 35CrMo for medium-duty applications, while heavy-duty applications demand forged 42CrMo steel to ensure structural integrity under extreme loads.

Bearing components within universal shaft couplings also require careful material selection. Needle bearings, which are commonly used in cardan couplings due to their high load-carrying capacity and compact size, are typically made from high-carbon chromium bearing steel (such as GCr15) or carburized steel. These materials offer excellent wear resistance and fatigue strength, essential for withstanding the oscillating loads and high contact pressures in the bearing interface. In applications where maintenance is difficult or where self-lubrication is required, sliding bearings made from bronze alloys or self-lubricating composite materials may be used. These materials reduce the need for frequent lubrication, making them suitable for harsh or remote environments. For specialized applications, alternative materials are employed to address specific challenges. In corrosive environments such as marine or chemical processing applications, stainless steel (304 or 316) or surface-treated alloys (nickel plating, galvanizing) are used to prevent rust and degradation. High-temperature applications, such as those in metallurgical furnaces or gas turbines, require materials with enhanced thermal stability, such as 35CrMo alloy steel with high-temperature coatings. For lightweight applications in aerospace or automotive industries, aluminum or titanium alloys may be used, although these materials typically have lower load-carrying capacities and require careful design optimization to ensure performance.

The versatility of universal shaft couplings is reflected in their extensive range of applications across numerous industries, where they play a critical role in ensuring the efficient and reliable operation of machinery. In the automotive industry, universal shaft couplings are essential components of drive train systems, connecting the transmission to the drive axle in rear-wheel-drive vehicles and serving as CV joints in front-wheel-drive and all-wheel-drive vehicles. They accommodate the vertical movement of the wheels caused by road irregularities, ensuring continuous power transmission while maintaining vehicle stability and handling. In heavy machinery and construction equipment—such as excavators, cranes, and bulldozers—universal shaft couplings are used in hydraulic systems, engine-transmission connections, and implement drives. These applications demand robust couplings capable of handling high torque loads, shock loads, and large angular misalignments, making cardan couplings and double universal couplings the preferred choices. The metallurgical industry relies heavily on universal shaft couplings in rolling mills, where they transmit power to the rolls while accommodating the adjustment of roll gaps during the rolling process. The high torque requirements and harsh operating conditions (high temperature, dust, vibration) in this industry necessitate couplings made from high-strength alloys with enhanced wear and heat resistance.

Aerospace and marine applications represent some of the most demanding environments for universal shaft couplings, requiring exceptional reliability, precision, and resistance to extreme conditions. In aerospace, they are used in aircraft control systems, connecting the pilot's input controls to the control surfaces (ailerons, elevators, rudders), and in helicopter rotor drive systems, where they transmit power from the engine to the rotor while accommodating the dynamic misalignments caused by rotor movement. These applications demand lightweight, high-precision CV couplings made from titanium or high-strength aluminum alloys to minimize weight while ensuring structural integrity. In marine propulsion systems, universal shaft couplings connect the engine to the propeller shaft, accommodating the misalignments caused by hull flexure and thermal expansion. Corrosion resistance is a key requirement here, leading to the use of stainless steel or corrosion-resistant alloys with protective coatings. Other notable applications include industrial conveyor systems, where double universal couplings enable power transmission over long distances with varying misalignments, and precision machine tools, where CV couplings ensure smooth, constant-velocity rotation critical for maintaining machining accuracy.

The proper selection of a universal shaft coupling is essential to ensure optimal performance, reliability, and longevity of the mechanical system. The selection process involves evaluating several key factors, including torque requirements, rotational speed, misalignment type and magnitude, space constraints, environmental conditions, and maintenance accessibility. Torque capacity is the primary consideration, as the coupling must be capable of handling the maximum operating torque of the system, including transient peak torques caused by startup or load fluctuations. Engineers calculate the required torque capacity using the formula Tc = K × T, where T is the nominal torque (derived from the power and speed of the driving shaft using T = 9550 × Pw / n, with Pw being power in kilowatts and n being speed in rpm) and K is the load factor, which accounts for load characteristics (smooth, pulsating, or shock loads). For example, a motor-driven system with smooth loads may use a load factor K = 1, while a diesel-driven system with shock loads may require K = 1.2 or higher. The selected coupling's nominal torque (Tn), fatigue torque (Tf), and pulsating torque (Tp) ratings must all exceed the calculated torque capacity to ensure safe operation. The nominal torque is the maximum torque the coupling can handle under ideal conditions (low speed, small misalignment, smooth loads), while the fatigue torque is the maximum torque for long-term cyclic operation, and the pulsating torque is for unidirectional operation with load fluctuations.

Rotational speed is another critical factor, as high-speed operation can lead to centrifugal forces, vibration, and heat generation. Single universal joints are limited to low-to-medium speeds due to speed fluctuations, while CV couplings and double universal couplings are suitable for high-speed applications. The coupling's maximum allowable speed is determined by its design, material properties, and balance quality. High-speed couplings require precise dynamic balancing to minimize vibration, with imbalance limits typically specified as grams per millimeter (g·mm) per unit weight. Misalignment tolerance must be matched to the application's requirements, with angular misalignment typically ranging from 3° to 15° depending on the coupling type. Cardan couplings can accommodate larger angular misalignments (up to 15°) but with speed fluctuations, while CV couplings typically handle smaller angles (up to 8°) but with constant velocity. Space constraints—both radial and axial—also influence selection. Radial space limitations may require compact designs such as needle-bearing cardan couplings, while axial space limitations may favor telescoping universal couplings that can accommodate axial displacement without additional space. Environmental conditions such as temperature, corrosion, and contamination must be considered when selecting materials and seals. High-temperature environments require heat-resistant materials and lubricants, while corrosive environments demand stainless steel or coated components. Finally, maintenance accessibility should be evaluated, as some couplings require regular lubrication and inspection, while others (such as self-lubricating designs) are intended for low-maintenance or maintenance-free operation.

Proper installation and maintenance are crucial to extending the lifespan of universal shaft couplings and preventing premature failure. Installation errors, such as improper alignment, over-tightening of fasteners, or incorrect shaft fit, can lead to increased wear, vibration, and early failure. The first step in installation is ensuring accurate shaft alignment using tools such as laser alignment systems or dial indicators. Angular misalignment should be kept within the coupling's allowable limits, typically ≤ 0.05° for high-precision applications, and axial misalignment ≤ 0.1 mm per meter of shaft length. Fasteners (bolts, nuts) should be tightened to the recommended torque using a torque wrench, following a diagonal sequence to ensure uniform clamping force. Over-tightening can cause distortion of the yokes or shafts, while under-tightening can lead to loose connections and vibration. Shaft fit is also important, with a proper interference fit (press fit) or transition fit ensuring a secure connection without excessive stress.

Lubrication is one of the most important maintenance practices, as it reduces friction between moving parts, prevents wear, and dissipates heat. The type of lubricant depends on the application's operating conditions, including temperature, speed, and environmental contamination. For most industrial applications, lithium-based greases (NLGI Grade 2) are suitable, while high-temperature applications require synthetic greases such as composite calcium sulfonate greases (operating temperature range -40℃ to 180℃). Lubrication intervals vary depending on the coupling type and operating conditions, with typical intervals ranging from 500 to 2000 operating hours. The lubricant should be applied until it exits the seal, ensuring complete coverage of the bearing surfaces, and old or contaminated lubricant should be thoroughly cleaned before re-lubrication. Sealing is also critical to prevent lubricant leakage and contamination by dust, water, or other debris. Damaged or aged seals should be replaced promptly, with skeleton or seals recommended for harsh environments. Regular inspection is essential to detect early signs of failure, such as wear, corrosion, vibration, or abnormal noise. Inspection should include checking for loose fasteners, excessive play in the joints (more than 0.3 mm may indicate bearing wear), seal damage, and lubricant contamination. Vibration analysis and temperature monitoring can also be used to identify potential issues before they lead to catastrophic failure. For example, increased vibration may indicate misalignment or worn bearings, while elevated temperature may signal lubrication failure or overload.

Common issues encountered with universal shaft couplings include abnormal vibration and noise, bearing wear and spider failure, lubrication failure, and shaft misalignment-related wear. Abnormal vibration is often caused by worn bearings, excessive joint play, or unbalanced components. The solution typically involves replacing worn parts, re-balancing the coupling and shafts, and correcting alignment. Bearing wear and spider failure are commonly due to overload, inadequate lubrication, or contamination. To address these issues, the root cause (overload, poor lubrication) should be identified and corrected, and worn components should be replaced with parts of the correct material and specification. Lubrication failure, indicated by dry or contaminated lubricant, overheating, or leakage, requires cleaning the lubrication system, replacing the lubricant with the correct type, and repairing or replacing damaged seals. Misalignment-related wear, such as uneven yoke wear or shaft scoring, is resolved by re-aligning the shafts using precision tools and ensuring proper fit between the coupling and shafts. In some cases, adding shims to the coupling mount or using adjustable yokes can help compensate for misalignment.

Looking to the future, the development of universal shaft couplings is likely to be driven by advancements in materials science, manufacturing technology, and smart monitoring systems. The use of composite materials, such as carbon fiber-reinforced polymers, is expected to increase, offering a combination of lightweight, high strength, and corrosion resistance that is ideal for aerospace and automotive applications. Additive manufacturing (3D printing) technology may enable the production of complex coupling designs with optimized geometries, reducing weight and improving load distribution. Smart monitoring systems, incorporating sensors for torque, temperature, vibration, and wear, are being integrated into couplings to enable predictive maintenance, allowing operators to detect potential issues before they cause failure. These sensors transmit real-time data to a central monitoring system, enabling condition-based maintenance and reducing unplanned downtime. Additionally, the demand for more efficient and environmentally friendly couplings is driving the development of self-lubricating materials and low-friction designs that minimize energy loss and reduce the need for lubricants, which can be harmful to the environment.

In conclusion, universal shaft couplings are essential components in mechanical power transmission systems, enabling the seamless transfer of torque between misaligned shafts across a wide range of applications. Their diverse structural designs, from basic cardan couplings to precision CV couplings, are tailored to meet the specific requirements of different industries, including automotive, aerospace, metallurgical, and marine. Material selection, driven by operating conditions and load requirements, plays a critical role in ensuring performance and durability, with high-strength alloys being the primary choice for most applications. Proper selection, installation, and maintenance are key to maximizing the lifespan of universal shaft couplings, with careful attention to torque capacity, alignment, lubrication, and inspection. As technology advances, the integration of smart monitoring systems and advanced materials is expected to further enhance the performance, reliability, and efficiency of universal shaft couplings, ensuring their continued relevance in the evolving landscape of mechanical engineering. Whether in heavy industrial machinery or precision aerospace systems, universal shaft couplings remain a vital link in the chain of power transmission, enabling the smooth and efficient operation of the machinery that powers modern society.

« Universal Shaft Couplings » Update Date: 2026/1/10

URL: https://m.rokee.com/tags/universal-shaft-couplings.html