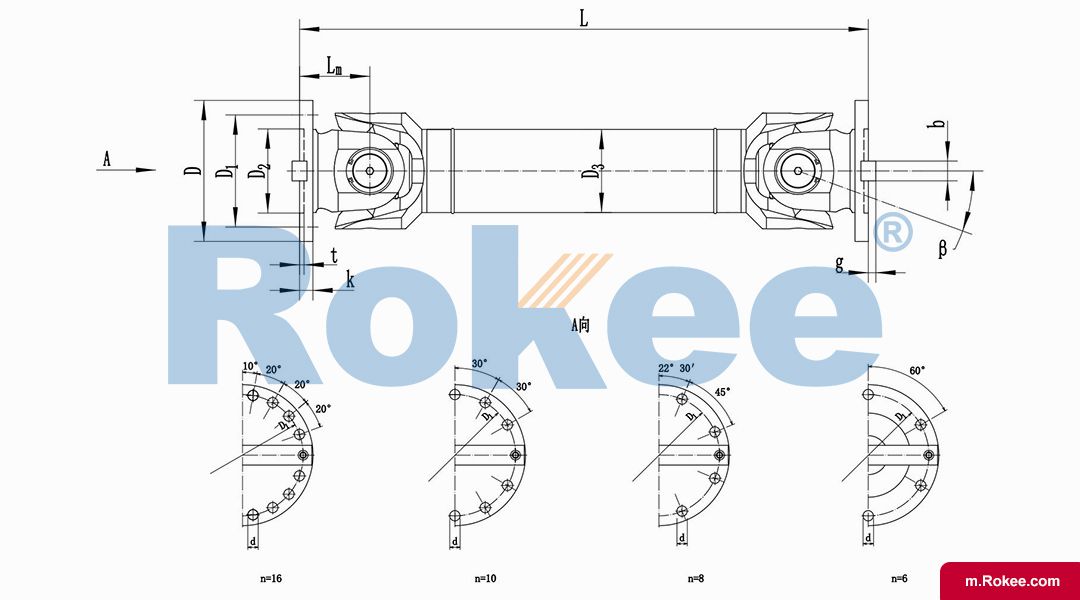

SWC-WH non-telescopic welded universal joint coupling

| Model | Rotary Diameter D mm | Nominal Torque Tn KN ·m | Fatigue Torque Tf KN ·m | Bearing Life Coefficient KL | Axis Angle β (°) | Size / mm | Rotational Inertia (kg ·m2) | Quality kg | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lmin | D1 (js11) | D2 (H7) | D3 | Lm | n×φd | k | t | b (h9) | g | Lmin mm | Increase 100mm | Lmin mm | Increase 100mm | ||||||

| SWC100WH | 100 | 2.5 | 1.25 | 5.795×10-4 | ≤25 | 243 | 84 | 57 | 60 | 55 | 6×φ9 | 7 | 2.5 | 一 | 一 | 0.004 | 0.0002 | 4.5 | 0.35 |

| SWC120WH | 120 | 5 | 2.5 | 4.641×10-3 | ≤25 | 307 | 102 | 75 | 70 | 65 | 8×φ11 | 8 | 2.5 | 一 | 一 | 0.01 | 0.0004 | 7.7 | 0.55 |

| SWC150WH | 150 | 10 | 5 | 0.51×10-1 | ≤25 | 350 | 130 | 90 | 89 | 80 | 8×φ13 | 10 | 3 | 一 | 一 | 0.037 | 0.0016 | 18 | 0.85 |

| SWC180WH | 180 | 22.4 | 11.2 | 0.245 | ≤15 | 480 | 155 | 105 | 114 | 110 | 8×φ17 | 17 | 5 | 24 | 7 | 0.15 | 0.007 | 48 | 2.8 |

| SWC200WH | 200 | 36 | 18 | 1.115 | ≤15 | 500 | 170 | 120 | 133 | 115 | 8×φ17 | 17 | 5 | 28 | 8 | 0.246 | 0.013 | 72 | 3.7 |

| SWC225WH | 225 | 56 | 28 | 7.812 | ≤15 | 520 | 196 | 135 | 152 | 120 | 8×φ17 | 20 | 5 | 32 | 9 | 0.365 | 0.023 | 78 | 4.9 |

| SWC250WH | 250 | 80 | 40 | 2.82×101 | ≤15 | 620 | 218 | 150 | 168 | 140 | 8×φ19 | 25 | 6 | 40 | 12.5 | 0.847 | 0.028 | 124 | 5.3 |

| SWC285WH | 285 | 120 | 58 | 8.28×101 | ≤15 | 720 | 245 | 170 | 194 | 160 | 8×φ21 | 27 | 7 | 40 | 15 | 1.756 | 0.051 | 185 | 6.3 |

| SWC315WH | 315 | 160 | 80 | 2.79×102 | ≤15 | 805 | 280 | 185 | 219 | 180 | 10×φ23 | 32 | 8 | 40 | 15 | 2.893 | 0.08 | 262 | 8 |

| SWC350WH | 350 | 225 | 110 | 7.44×102 | ≤15 | 875 | 310 | 210 | 245 | 194 | 10×φ23 | 35 | 8 | 50 | 16 | 4.814 | 0.146 | 349 | 11.5 |

| SWC390WH | 390 | 320 | 160 | 1.86×103 | ≤15 | 955 | 345 | 235 | 267 | 215 | 10×φ25 | 40 | 8 | 70 | 18 | 8.406 | 0.222 | 506 | 15 |

| SWC440WH | 440 | 500 | 250 | 8.25×103 | ≤15 | 1155 | 390 | 255 | 325 | 260 | 16×φ28 | 42 | 10 | 80 | 20 | 15.79 | 0.474 | 790 | 21.7 |

| SWC490WH | 490 | 700 | 350 | 2.154×104 | ≤15 | 1205 | 435 | 275 | 351 | 270 | 16×φ31 | 47 | 12 | 90 | 22.5 | 27.78 | 0.690 | 1104 | 27.3 |

| SWC550WH | 550 | 1000 | 500 | 6.335×104 | ≤15 | 1355 | 492 | 320 | 426 | 305 | 16×φ31 | 50 | 12 | 100 | 22.5 | 48.32 | 1.357 | 1526 | 34 |

SWC-WH Cardan Shaft, also known as SWC-WH type non expansion welded universal coupling, is a high-performance transmission component widely used in multiple industrial fields.

SWC-WH Cardan Shaft is mainly used for transmitting torque in mechanical shaft systems of metallurgy, lifting, engineering transportation, mining, petroleum, shipbuilding, coal, rubber, papermaking machinery and other heavy machinery industries. Its design enables the two shafts to achieve continuous rotation and reliable transmission of torque and motion when they are not on the same axis and there is an angle between the axes.

Main Features

Strong angle compensation capability: SWC-WH Cardan Shaft has a large angular compensation capability, and its axis angle is generally between 5 ° -45 °, which can adapt to complex and variable transmission requirements.

Compact and reasonable structure: Adopting an integral fork design, the structure is compact and reasonable, allowing the coupling to maintain high stability and reliability even when transmitting high power.

Large bearing capacity: Compared with other types of couplings with the same rotational diameter, SWC-WH universal couplings transmit greater torque, making them particularly suitable for mechanical equipment with limited rotational diameter.

High transmission efficiency: The transmission efficiency can reach 98% -99.8%, with significant energy-saving effect, especially suitable for high-power transmission occasions.

Smooth transportation and low noise: Due to the rationality of structural design and material selection, the SWC-WH Cardan Shaft can maintain a low noise level during operation, while running smoothly, improving the comfort of equipment use.

Easy installation, disassembly, and maintenance: The structural design of the coupling facilitates disassembly, assembly, and maintenance, reducing equipment downtime and maintenance costs.

SWC-WH universal coupling has a variety of models and specifications to meet different transmission needs. For example, models such as SWC100WH, SWC120WH, and SWC150WH have different parameters such as turning diameter, nominal torque, and fatigue torque. Users can choose the appropriate model and specifications based on their actual transmission needs.

SWC-WH Cardan Shaft is a high-performance and versatile transmission component widely used in multiple industrial fields. When making a purchase, users should pay attention to factors such as the manufacturer's qualifications, product performance parameters, and price and cost-effectiveness to ensure that they find the right product.

URL: https://m.rokee.com/swc-cardan-shaft-couplings/swc-wh-cardan-shaft.html