Rokee is a chinese Jaw Couplings Manufacturer, provide Jaw Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Jaw Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Jaw Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

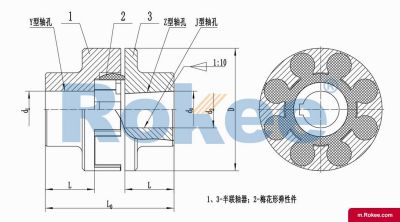

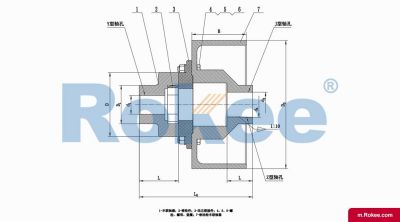

LM/ML Flexible Plum Jaw Coupling

LM Plum-shaped Flexible Coupling is the basic form of this series of couplings.View More -

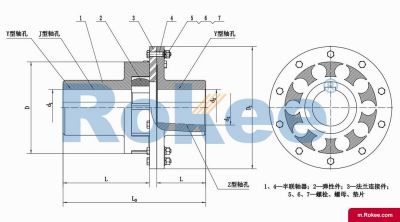

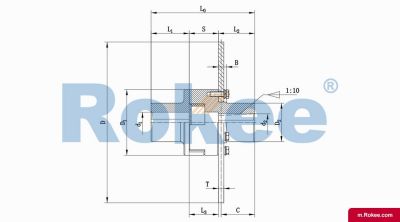

LMD/MLZ Flexible Plum Jaw Coupling With Single Flange

LMD Plum-shaped Flexible Coupling is added with transition connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View More -

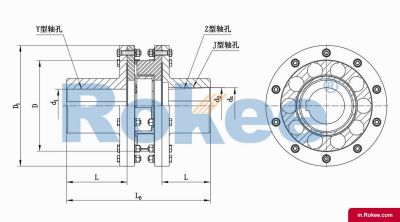

LMS/MLS Flexible Plum Jaw Coupling With Double Flange

LMS Plum-shaped Flexible Coupling adopts double transition flange connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View More -

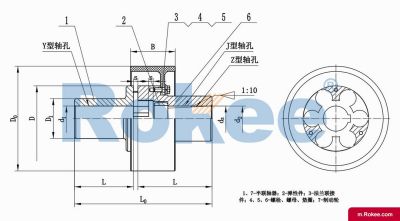

LMZ-I/MLL-I Flexible Plum Jaw Coupling With Split Brake Wheel

LMZ-I Plum-shaped Flexible Coupling adopts split brake wheel design, suitable for situations where braking is required.View More -

LMZ-II/MLL-II Flexible Plum Jaw Coupling With Integral Brake Wheel

LMZ- II Plum-shaped Flexible Coupling adopts integral brake wheel design, suitable for situations where braking is required.View More -

LMPK/MLPK Flexible Plum Jaw Coupling With Split Brake Disc

LMPK Plum-shaped Flexible Coupling adopts split brake disc design, suitable for situations where braking is required and eliminating the need of axially moving the semi-coupling when replacing the elastomer.View More

The jaw coupling consists of three core components:

Two metal claw plates: usually made of 45 steel, aluminum alloy or stainless steel material is used under special working conditions. The claw plate undergoes precision machining such as turning, milling, and pulling, and is subjected to overall heat treatment to ensure mechanical strength.

Elastic element: a plum blossom shaped polyurethane or rubber elastic body located between two claw disks, with different designs such as 4 petals, 6 petals, 8 petals, or 10 petals, and optional hardness (commonly 92A, 98A, 64D Shore hardness).

Working principle: Transmit torque and compensate for shaft deviation through compression deformation of elastic elements. When there is relative displacement between the two axes, the elastic body undergoes corresponding deformation, achieving automatic compensation function while absorbing vibration and impact energy.

performance advantage

Compensation capability: capable of compensating for axial (± 0.5mm), radial (± 0.5mm), and angular (± 1 °) deviations simultaneously

Vibration damping performance: The vibration attenuation rate can reach over 30%, especially suitable for impact load situations

Electrical insulation: resistance value>10 ¹² Ω, effectively blocking shaft current

No backlash transmission: Curved claw design achieves zero backlash (accuracy ≤ 0.05mm)

Maintenance free: No lubrication required, with a typical lifespan of up to 10 years (consistent with the lifespan of elastomers)

Main Categories

Traditional straight claw type: an economical solution suitable for ordinary motor transmission

Curved Claw Type (Zero Gap Type): Servo level accuracy, used for precision transmission of CNC machine tools, robotic arms, and other precision drives

Double section design: vibration attenuation rate increased by 40%, suitable for high-frequency vibration occasions such as pump sets

jaw couplings are widely used in the following scenarios:

Precision machinery: CNC machine tools (machining centers, engraving machines), semiconductor equipment

Industrial transmission: pump sets, fans, compressors

Material transportation: conveyors, cranes, lifting equipment

Automation equipment: robotic arm, linear module, servo drive system

Special Environment: Food Machinery, Mining Machinery (Dustproof Design)

As a key component of mechanical transmission systems, the correct selection and installation of jaw couplings directly affect the reliability and lifespan of the entire equipment operation. It is recommended to comprehensively consider dynamic load spectrum, environmental factors, and cost-effectiveness when selecting, and consult professional technical personnel for systematic analysis if necessary.

« Jaw Couplings » Post Date: 2024/5/8

URL: https://m.rokee.com/tags/jaw-couplings.html