Rokee is a chinese Universal Joint Shafts Manufacturer, provide Universal Joint Shafts processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Universal Joint Shafts selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Universal Joint Shafts is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

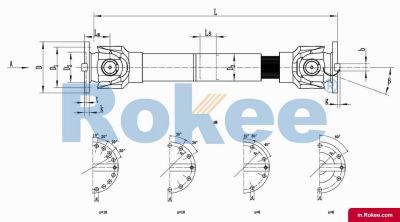

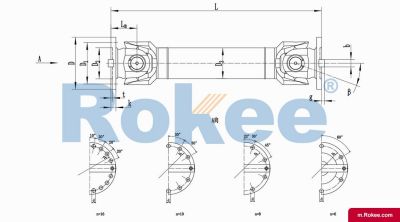

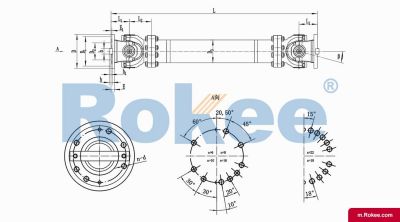

SWC-BH Cardan Shaft

SWC-BH standard telescopic welded universal joint couplingView More -

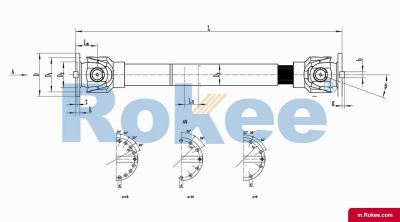

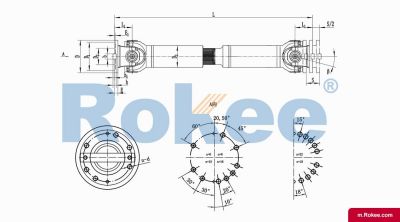

SWC-CH Cardan Shaft

SWC-CH long telescopic welded universal joint couplingView More -

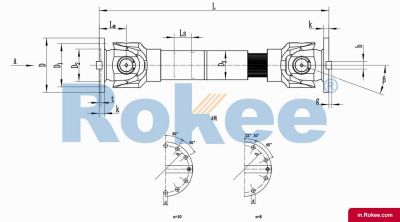

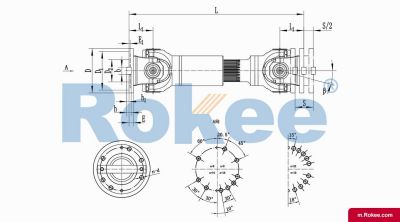

SWC-DH Cardan Shaft

SWC-DH short telescopic welded universal joint couplingView More -

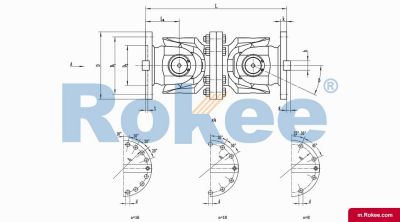

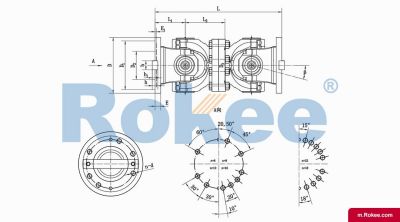

SWC-WD Cardan Shaft

SWC-WD non-telescopic short universal joint couplingView More -

SWC-WH Cardan Shaft

SWC-WH non-telescopic welded universal joint couplingView More -

SWP-A Cardan Shaft

SWP-A telescopic long type universal joint couplingView More -

SWP-B Cardan Shaft

SWP-B telescopic short type universal joint couplingView More -

SWP-C Cardan Shaft

SWP-C non telescopic short type universal joint couplingView More -

SWP-D Cardan Shaft

SWP-D non telescopic long type universal joint couplingView More

As a core component in the field of mechanical transmission, Universal Joint Shafts play a crucial role in modern industrial equipment. This mechanical device that can achieve variable angle power transmission, with its unique structural design and flexible motion characteristics, solves the problem of power transmission between rotating shafts with intersecting axes or frequently changing relative positions. From heavy-duty rolling mills to precision automotive drive systems, from mining machinery to aviation equipment, the application of Universal Joint Shaft shafts covers almost all industrial fields that require flexible transmission.

Universal Joint Shaft shaft is a mechanical transmission device used to connect two shafts whose axes do not coincide or whose relative positions change during operation. It can achieve reliable power transmission within a certain angle range. This unique connection mechanism no longer limits the equipment to strict axis alignment requirements, providing greater flexibility and adaptability for mechanical design. The core function of a Universal Joint Shaft shaft is to compensate for the angle deviation between two shafts. Depending on the type, the allowable axis angle is usually between 5 ° -45 °, and some special designs can even achieve larger deflection angles.

The basic working principle of Universal Joint Shaft is based on the principles of spatial geometry and kinematics. Taking the most common cross axis Universal Joint Shaft as an example, it forms two mutually perpendicular rotation axes through the combination of a cross axis and two Universal Joint Shaft forks. When the driving shaft rotates, the driven shaft also rotates along with it through the transmission of the cross shaft, while allowing a certain angle between the two shafts. This design allows power to be transmitted from one axis to another axis that does not coincide, solving the transmission problem of axis misalignment. However, it should be noted that a single Universal Joint Shaft shaft has velocity fluctuation characteristics when transmitting motion, that is, the instantaneous angular velocity of the output shaft is not exactly the same as that of the input shaft, but varies periodically, and this inequality is directly related to the size of the angle between the two shafts.

In order to overcome the speed fluctuation problem in single Universal Joint Shaft transmission, the dual Universal Joint Shaft system has emerged. When two Universal Joint Shaft shafts are used and arranged in a specific way, this speed fluctuation can be eliminated, achieving constant speed transmission. Specifically, three conditions need to be met: the Universal Joint Shaft forks at both ends of the intermediate shaft must be in the same plane; The angle between the intermediate shaft and the driving shaft, as well as the driven shaft, must be equal; The axes of the driving shaft, driven shaft, and intermediate shaft should be located in the same plane. This arrangement is widely used in automotive transmission systems and other situations that require constant speed transmission, reflecting the pursuit of motion accuracy in mechanical design.

From the perspective of mechanical properties, Universal Joint Shaft shafts need to withstand additional bending moments and vibration loads caused by axis deflection while transmitting torque. Its load-bearing capacity depends on various factors such as material strength, bearing performance, and structural stiffness. In practical applications, the design of Universal Joint Shaft shafts must comprehensively consider parameters such as transmitted torque, speed range, allowable deflection angle, and working environment to ensure the reliability and service life of the transmission system. With the development of computing technology and materials science, the design of modern Universal Joint Shaft shafts has been able to achieve greater torque transmission, higher speed capability, and longer service life, continuously promoting the progress of mechanical transmission technology.

Sliding Universal Joint Shaft shaft is a traditional structural form used in heavy equipment such as rolling mills. Its typical structure consists of key components such as flat head, fork head, pin shaft, and sliding block. This type of joint works according to the Hooke cross hinge principle, achieving high torque transmission between inclined shafts through dual axis rotation. The hinge structure of the slider type Universal Joint Shaft shaft is divided into two types: open and closed. The open hinge adopts a crescent shaped slider and a pin shaft, which is suitable for axial roll changing mills; The closed hinge is fixed by a through type circular pin shaft, which can be disassembled laterally. The new self supplied sliding Universal Joint Shaft shaft developed by Shanghai Maode Group represents the improvement direction of this technology. It adopts split rolling bearings and a thin oil circulation lubrication system, effectively reducing wear and achieving automatic oil supply. The manufacturing process requirements for the slider type Universal Joint Shaft shaft are extremely high, covering processes such as electric slag remelting smelting, CNC precision machining, and deep hole drilling machine oil hole processing. It is necessary to strictly control the quality and dimensional tolerances of the forgings. Although this type of joint can transmit large torque at large inclination angles, it has gradually been replaced by the cross wrap Universal Joint Shaft in modern rolling mills due to its disadvantages of high sliding friction loss and low efficiency.

The cross axis Universal Joint Shaft is currently the most widely used type in industrial applications, which is precisely assembled by two fork shaped heads and a cross axis through rolling bearings. According to the principle of Hooke hinge, the torque transmission capacity of modern heavy-duty cross axis Universal Joint Shaft can reach 8000-10000kN · m, which is impressive. According to the different fork structures, it can be further divided into two layouts: SWC type integral fork and SWP type split fork. SWC type adopts an integral fork head design, which is more sturdy in structure; The SWP type split fork is easy to install and maintain. The torque range of the series of cross universal shafts produced by ELBE company in Germany ranges from 6Nm to 450Nm, with a maximum deflection angle of 45 ° and a maximum speed of 5000r/min. Users can choose the connection method with standard holes or key slot holes according to their needs. A key improvement of the cross axis Universal Joint Shaft shaft is the use of radial rolling thrust bearing design, which makes it possible to transmit large torque in small space diameters. This type of joint is widely used in heavy equipment such as pipe mills, medium and thick plate mills, and lifting and transportation machinery. Its turning diameter can reach 1600mm, torque transmission distance exceeds 30m, and it supports non-standard customization services to meet special working conditions.

Ball cage Universal Joint Shaft (also known as ball cage Universal Joint Shaft) is a representative structure of constant velocity Universal Joint Shaft, widely used in automotive drive systems and precision machinery. Its core components include a star shaped sleeve, spherical shell, cage, and six steel balls, which achieve power transmission through precise ball path coordination. The biggest feature of the cage type Universal Joint Shaft is that it can ensure that the instantaneous angular velocity of the input shaft and output shaft is always equal, completely solving the speed fluctuation problem of ordinary Universal Joint Shafts. According to whether axial movement is allowed, ball cage Universal Joint Shafts are divided into two types: fixed type and telescopic type. Fixed type RF joints are mainly used on the wheel side, allowing for significant changes in axle to axle angles (up to a maximum of 47 °); The telescopic VL joint is commonly used on the transmission side, which can compensate for angular deviation and adapt to axial displacement. The cage type Universal Joint Shaft has a compact structure, high transmission efficiency, and can withstand both radial and axial forces simultaneously. In modern front wheel drive vehicles, each drive half shaft is usually equipped with two cage type Universal Joint Shafts (one on the inside and one on the outside) to meet the composite motion requirements of steering and suspension jumping.

« Universal Joint Shafts » Post Date: 2024/5/6