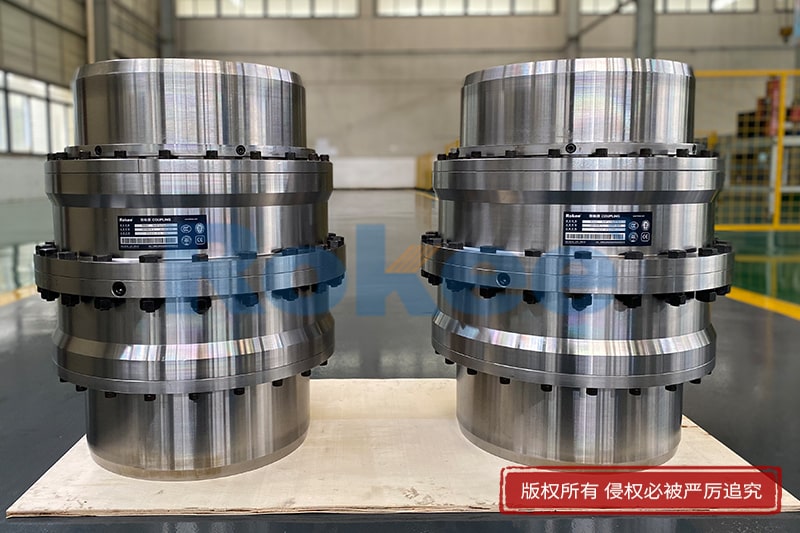

Rokee® Customized RODA Gear Type Coupling Exported to Vietnam for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

RODA gear type coupling is an innovative design of rigid flexible coupling, consisting of a precision matched inner gear ring and a flange half coupling with outer teeth. Compared with traditional spur gear couplings, the outer teeth adopt a spherical drum design, with the tooth surface centered on the gear axis in a spherical shape, while increasing the tooth flank clearance. This special structure is based on engineering optimization of complex force analysis, which enables the coupling to achieve simultaneous contact of multiple teeth during transmission, significantly improving load distribution.

The core advantages are reflected in:

Excellent compensation capability: allows for larger axial, radial, and angular displacement compensation (allowable angular displacement can reach 1 ° 30 ′, 50% higher than spur gear couplings)

Load bearing capacity improvement: At the same size, the load bearing capacity is 15-20% higher than that of a spur gear coupling, and the maximum torque bearing capacity can reach 8.19 million Newton meters

Extended service life: Optimize the contact conditions of the tooth surface, avoid the edge compression problem of the straight tooth coupling, and extend the service life by 30-50%

High transmission efficiency: The transmission efficiency is as high as 99.7%, and the noise control performance is excellent

Convenient maintenance: The outer gear sleeve tooth end is designed in a trumpet shape, greatly simplifying the disassembly and assembly process

RODA gear type couplings are widely used in the heavy industry field:

Metallurgical industry: low-speed heavy-duty equipment such as rolling mills and continuous casting machines, capable of withstanding impact loads and frequent start stop cycles

Mining machinery: equipment with harsh working conditions such as crushers and ball mills

Lifting and transportation: equipment such as bridge cranes and port machinery that require braking function

Energy field: connection between wind turbine gearbox and generator, compensation for impeller deflection deformation, transmission of turbine shaft system (requiring dynamic balancing treatment)

General Machinery: Pumps, fans, compressors, and other applications that require high reliability transmission

The core innovation of RODA coupling lies in the spherical drum shaped design of the external teeth:

The tooth crest and tooth surface are both arc-shaped, forming a double joint flexible structure

The drum curve is mostly designed as a circular arc, and the curvature radius is proportional to the unilateral thinning of the inner teeth

By optimizing the radius of the bulge circle (as large as possible), we can avoid edge contact, reduce concentrated load on the gear teeth, and improve the friction conditions on the tooth surface

Structural optimization

Short axis design: reduces the aspect ratio and makes the structure more compact

High pressure angular profile: improving load-bearing capacity

Modular design: Good universality of components, standardized bolts of similar models

Lightweight: Compared with the national standard coupling, the weight is reduced by more than 30%, and the moment of inertia is small

Selection considerations

Torque requirement: Select the model based on the maximum working torque and peak torque of the transmission system

Speed range: Ensure that the working speed does not exceed the allowable speed of the coupling

Compensation demand: Evaluate the axial, radial, and angular deviations of the system

Environmental conditions: Consider environmental influences such as temperature, humidity, dust, etc

Special functions: such as whether additional functions such as braking and torque limitation are required

Installation precautions

Alignment requirement: Although the gear type coupling has strong compensation capability, the alignment accuracy should still be improved as much as possible

Lubrication management: Use designated brand lubricating oil/grease to ensure the normal operation of the lubrication system (especially for forced lubrication models), regularly check the oil quality and quantity

Gap adjustment: Maintain an appropriate assembly gap (A value) for maintenance purposes

Bolt tightening: Use a torque wrench to evenly tighten the connecting bolts

RODA drum tooth coupling has demonstrated significant advantages in the field of heavy-duty transmission through innovative drum tooth design and structural optimization. Its excellent deviation compensation capability, high transmission efficiency, and long service life make it an ideal choice for industries such as metallurgy, mining, and energy. The correct selection, installation, and maintenance are key to ensuring optimal performance of the coupling, and modular design and diverse models provide flexible solutions for different application scenarios. With the advancement of technology, gear type couplings will continue to develop towards smarter and more efficient directions.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/roda-gear-type-coupling-exported-to-vietnam.html