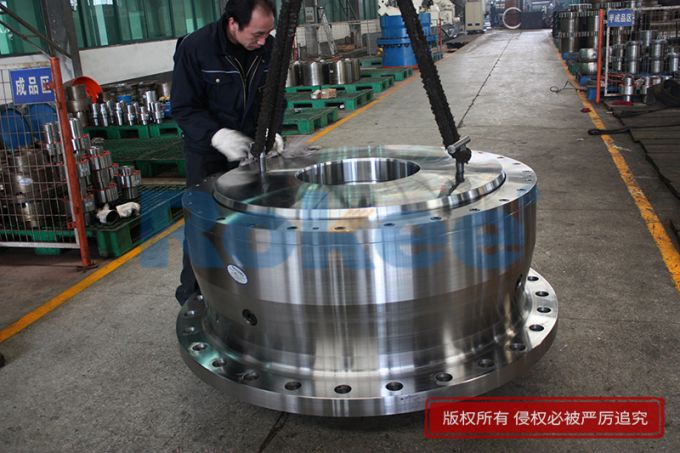

Rokee® Customized Large Curved-tooth Gear Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

As the core component of modern industrial transmission, the curved-tooth gear coupling has become the preferred transmission solution in heavy load fields such as metallurgy, mining, and lifting transportation due to its excellent three-dimensional compensation capability and high torque density characteristics.

The curved-tooth gear coupling adopts a double joint flexible design, and its core components include:

Drum shaped outer gear sleeve: The tooth tip has a spherical contour, and the tooth thickness gradually decreases by 0.15-0.3mm from the middle to both ends. Through five axis linkage CNC forming processing, continuous gradient contact of the tooth surface is achieved. This design ensures even distribution of contact stress and avoids stress concentration at the end of the spur gear coupling.

Internal gear ring: Made of 42CrMoA alloy steel forged as a whole, the tooth surface hardness reaches HRC58-62 after carburizing and quenching treatment, and the core maintains the toughness of HB280-320. The internal backlash of the gear is increased by 30% -50% compared to standard gears, and it can still maintain a tooth contact rate of over 85% at an angular displacement of 1.5 °.

Lubrication system: High end models are equipped with forced thin oil lubrication devices, with oil pressure maintained at 0.2-0.4MPa and flow rate of 5-15L/min. Actual test data shows that compared to grease lubrication, thin oil lubrication can reduce tooth wear rate by 60% and extend service life by 3-5 times.

The torque transmission mechanism manifests as a dual path:

Tooth surface meshing transmission: It undertakes about 70% of the rated torque and achieves power transmission through the normal force decomposition of the involute tooth profile

Friction assisted transmission: 30% of torque is transmitted by end face friction, and pre tightening force is applied using 12.9 grade high-strength bolts

Dynamic compensation characteristic parameters:

Axial compensation: maximum 6mm

Radial deviation: 3mm allowed (to be controlled within the ideal range of 0.05-0.15mm)

Angular deflection: compensation capability of 2.5 ° (GIICL series)

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/large-curved-tooth-gear-coupling.html