Rokee is a chinese Tire Couplings Manufacturer, provide Tire Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Tire Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Tire Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

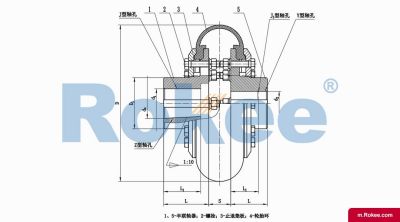

LLA Tyre Coupling

The LLA Tyre Coupling uses two semi-couplings to connect both sides of the elastic tyre body through internal pressing plates and bolts, making it easy to replace the elastic tyre body. The LLA Tyre Coupling is a kind of high elastic coupling, with good damping buffer and superior offset compensation performance.The working temperature of 20~80 degrees Celsius, transmitting torque 10~20000NM, suitable for damp, dust, shock, vibration, reversing the changeable and frequent starting working conditions, and convenient assembly and disassembly, no lubrication, durable and reliable. Non standard couplings are made in accordance with special needs. In overloading work and half coupling, there will be no malignant accidents.View More -

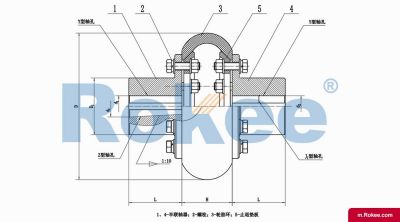

LLB Tyre Coupling

The LLB Tyre Coupling is a kind of high elastic coupling, with good damping buffer and superior offset compensation performance. The working temperature of 20~80 degrees Celsius, transmitting torque 10~20000NM, suitable for damp, dust, shock, vibration, reversing the changeable and frequent starting working conditions, and convenient assembly and disassembly, no lubrication, durable and reliable. Non standard couplings are made in accordance with special needs. In overloading work and half coupling, there will be no malignant accidents.View More -

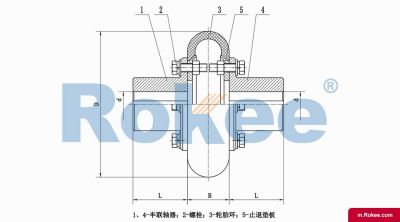

UL Tyre Coupling

UL Tyre Coupling adopts the structure of vulcanizing and bonding the tyre body with the metal connecting plate with threaded holes, which is then directly connected to the two semi-couplings by bolts for torque transmission and other displacement compensation.UL Tyre Couplings are flexible shaft coupling. UL type tire has good buffering performance. Operating temperature: -20~+80℃. Torque range: 10~25000N.M.UL Tyre Coupling mainly used in damp, dusty, vibration working environment. Because the elastic part is the whole tire, so, easy to disassemble and assemble. No lubrication is required.View More

The tire coupling is mainly composed of tire body, steel frame, and connecting bolts and other components. The tire body is the core component of the tire coupling, which is divided into two categories: convex and concave. Among them, convex is further divided into three types: integral with skeleton, integral without bone, and radial notch. Different types of tire couplings are suitable for different working conditions and requirements.

The working principle of tire couplings mainly relies on the frictional force generated between the tire ring and the flange end face to transmit torque. When the two halves of the coupling are connected together by bolts, tightening the bolts will cause the tire to tightly adhere to the flange end face, thereby generating sufficient friction. During the working process, the tire ring undergoes torsional shear deformation, so the tire coupling has high elasticity and can compensate for the relative displacement between the two shafts.

Performance characteristics

High elasticity: The tire coupling has high elasticity and can effectively compensate for the relative displacement between the two shafts, improving the dynamic characteristics of the transmission system.

Shock absorption and buffering: Tire couplings have good shock absorption and buffering performance, which can reduce mechanical vibration and noise, and improve the smoothness of equipment operation.

Simple structure: The tire coupling has a simple structure, does not require lubrication, and is easy to install, disassemble, and maintain.

Strong adaptability: Tire couplings are suitable for working conditions that are humid, dusty, subject to impact, vibration, variable forward and reverse rotation, and frequent starting.

The main models of tire couplings include UL type, LLB type, LLA type, etc. These models have different specifications and performance parameters, suitable for different mechanical transmission systems. For example, UL tire couplings have excellent shock absorption and buffering performance, making them suitable for equipment that requires high-precision transmission; LLB tire couplings are commonly used in metallurgical equipment and have good inter axis offset compensation performance.

Installation and maintenance precautions

Installation precautions: When installing tire couplings, ensure that the shaft hole form, diameter, and length of the two half couplings match the connected shaft. At the same time, measures should be taken to make the stress direction in the tire opposite to the stress direction generated during operation, in order to offset some additional axial forces and improve the working conditions of the coupling and two bearings.

Maintenance precautions: Regularly check the fastening, wear, and lubrication of the tire coupling. If abnormal sounds, excessive circumferential clearance, or loose connecting bolts are found, they should be dealt with in a timely manner.

The advantages of tire couplings mainly include high elasticity, good shock absorption and buffering performance, simple structure, and strong adaptability. However, it also has some drawbacks, such as low load-bearing capacity and large external dimensions. In addition, as the relative twist angle between the two axes increases, the tire shape may twist, resulting in a slight reduction in axial size and generating significant additional axial force on the two axes, thereby affecting the life of the bearings.

Tire couplings, as an important mechanical transmission component, play a crucial role in various mechanical transmission systems. When selecting and using, reasonable selection and maintenance should be carried out according to specific working conditions and requirements.

In the complex network of industrial power transmission systems, couplings serve as the critical link that connects rotating shafts, ensuring the smooth transfer of torque while accommodating inevitable misalignments and mitigating operational vibrations. Among the diverse range of coupling types available, the tire coupling stands out for its unique combination of flexibility, durability, and adaptability, making it a preferred choice in numerous industrial applications. Unlike rigid couplings that demand precise alignment and offer little to no vibration dampening, or specialized metal flexible couplings that may have limitations in shock absorption, the tire coupling leverages an elastomeric tire element to bridge the gap between performance, versatility, and ease of use. This component, often overlooked yet indispensable, plays a vital role in maintaining the efficiency and longevity of machinery across sectors such as manufacturing, mining, agriculture, and marine engineering, where reliable power transmission is paramount to operational success.

The fundamental structure of a tire coupling is relatively straightforward, yet its design is engineered to address key challenges in shaft connection. At its core, the coupling consists of three main components: two metal hubs, an elastomeric tire element, and connecting fasteners. The metal hubs are typically machined from high-strength materials such as carbon steel or alloy steel, ensuring they can withstand the torque loads transmitted from the driving shaft to the driven shaft. These hubs are designed to attach securely to the respective shafts, often through keyway connections, set screws, or hydraulic clamping systems, depending on the specific application requirements and torque capacity. The elastomeric tire, which gives the coupling its name, is the central flexible element that sits between the two hubs. This tire is usually made from synthetic rubber compounds, such as nitrile butadiene rubber (NBR), ethylene propylene diene monomer (EPDM), or polyurethane, each selected for its unique properties such as oil resistance, heat resistance, or wear resistance. The tire element is often reinforced with fabric or cord layers to enhance its tensile strength and torque-carrying capacity, ensuring it can withstand the mechanical stresses of continuous operation without premature failure. The connecting fasteners, which may include bolts, nuts, or clamping rings, secure the tire element to the hubs, creating a unified assembly that transmits torque while allowing for relative movement between the shafts.

The working principle of a tire coupling revolves around the elastic deformation of the tire element, which enables it to perform multiple critical functions simultaneously. When torque is applied to the driving shaft, the corresponding hub transfers this torque to the tire element, which in turn transmits it to the driven hub and shaft. Unlike rigid couplings, where torque is transferred directly through rigid contact, the tire coupling's elastomeric element deforms slightly under load, allowing it to compensate for various types of shaft misalignment. These misalignments can occur due to installation errors, thermal expansion and contraction of machinery during operation, or structural deflection caused by dynamic loads. The tire coupling is particularly effective at accommodating angular misalignment, where the shafts are inclined relative to each other, and parallel misalignment, where the shafts are offset horizontally. Additionally, the elastic nature of the tire element allows for a certain degree of axial displacement, where the shafts move towards or away from each other, further enhancing the coupling's adaptability. Beyond misalignment compensation, the elastomeric tire also acts as a vibration damper, absorbing and dissipating vibrational energy generated by the rotating shafts or the machinery itself. This vibration dampening capability is crucial for reducing noise levels, minimizing wear on other components such as bearings and gears, and improving the overall stability of the transmission system.

One of the most notable advantages of tire couplings is their exceptional flexibility and shock absorption capacity, which sets them apart from many other coupling types. In industrial environments where machinery is subject to sudden load changes, start-stop operations, or impact loads, the tire coupling's elastomeric element acts as a buffer, absorbing the shock and reducing the stress transmitted to the connected shafts and equipment. This not only protects the machinery from potential damage but also improves the comfort and safety of the working environment by reducing vibration and noise. Compared to metal flexible couplings such as diaphragm couplings or gear couplings, tire couplings offer superior vibration dampening due to the inherent properties of the elastomeric material. While diaphragm couplings excel in high-speed, precision applications and gear couplings are known for their high torque capacity, both lack the shock absorption capabilities of tire couplings, making them less suitable for applications with significant vibration or impact loads. Another key advantage of tire couplings is their ease of installation and maintenance. Due to their simple structure, tire couplings can be installed quickly without the need for specialized tools or precise alignment procedures, reducing downtime during setup or replacement. Maintenance requirements are also minimal, as the elastomeric tire element is typically the only component that may need replacement over time, and this can be done without disassembling the entire coupling or moving the connected shafts. This ease of maintenance translates to lower operational costs and increased productivity for industrial facilities.

The performance characteristics of tire couplings are highly dependent on the material selection of the elastomeric tire element, which is tailored to specific application requirements. Nitrile butadiene rubber (NBR) is a common choice for tire couplings used in applications where oil resistance is necessary, such as in hydraulic systems or machinery operating in environments with oil contamination. EPDM rubber, on the other hand, offers excellent resistance to heat, ozone, and weathering, making it suitable for outdoor applications or machinery operating at elevated temperatures. Polyurethane tire elements provide higher tensile strength and wear resistance compared to rubber, making them ideal for heavy-duty applications with high torque loads. The temperature range of tire couplings varies depending on the material, with most rubber tire elements operating effectively between -20°C and 80°C, and polyurethane elements capable of withstanding slightly higher temperatures up to 100°C. The torque capacity of tire couplings also varies widely, with small-scale models capable of transmitting torque as low as a few dozen newton-meters, while large industrial models can handle torque loads exceeding 10,000 newton-meters. This wide range of torque capacities makes tire couplings suitable for a diverse array of applications, from small electric motors in manufacturing equipment to large diesel engines in marine propulsion systems.

Tire couplings find applications in a wide variety of industrial sectors, thanks to their versatile performance characteristics. In the manufacturing industry, they are commonly used in conveyor systems, pumps, fans, and compressors, where their vibration dampening and misalignment compensation capabilities ensure smooth operation. Conveyor systems, in particular, benefit from the tire coupling's ability to handle the dynamic loads and misalignments that occur as materials are transported along the belt. In the mining industry, tire couplings are used in crushers, grinders, and conveyor systems, where they must withstand harsh operating conditions, including high torque loads, vibration, and exposure to dust and debris. The shock absorption capacity of tire couplings is particularly valuable in mining applications, where sudden impact loads from falling rocks or material can cause significant damage to machinery. In the agricultural sector, tire couplings are used in tractors, harvesters, and other farm equipment, where they adapt to the uneven terrain and variable loads encountered during field operations. The ease of maintenance of tire couplings is also a significant advantage in agricultural settings, where equipment may be operating in remote locations with limited access to maintenance facilities. In the marine industry, tire couplings are used in small to medium-sized vessels for connecting the engine to the propeller shaft, where their corrosion resistance (when using appropriate materials) and vibration dampening capabilities improve the reliability and comfort of the vessel.

While tire couplings offer numerous advantages, they also have certain limitations that must be considered when selecting a coupling for a specific application. One of the primary limitations is their lower torque capacity compared to gear couplings, which are designed for heavy-duty applications requiring the transmission of extremely high torque loads. In applications where torque exceeds the capacity of tire couplings, gear couplings or other heavy-duty coupling types may be more appropriate. Another limitation is the relatively lower operating temperature range of tire couplings compared to metal couplings. Diaphragm couplings, for example, can operate at temperatures up to 200°C or higher, making them suitable for high-temperature applications such as in steam turbines or industrial furnaces, where tire couplings would not be viable. Additionally, tire couplings are not suitable for applications with high rotational speeds, as the elastomeric tire element may experience excessive centrifugal force, leading to premature failure. In high-speed applications, diaphragm couplings or disc couplings are preferred due to their rigid construction and ability to withstand high rotational speeds without deformation.

Proper selection and maintenance of tire couplings are essential to ensure their optimal performance and longevity. When selecting a tire coupling, several factors must be considered, including the torque capacity, operating speed, temperature range, misalignment requirements, and environmental conditions. It is crucial to select a coupling with a torque capacity that exceeds the maximum operating torque of the application to ensure safety and reliability. The operating speed must also be within the manufacturer's recommended limits to prevent damage to the tire element. Environmental factors such as exposure to oil, chemicals, dust, or moisture should be taken into account when selecting the material of the tire element. For example, in environments with oil contamination, an NBR rubber tire element should be selected, while in outdoor environments, an EPDM rubber element would be more appropriate. Maintenance of tire couplings primarily involves regular inspection of the tire element for signs of wear, cracking, or degradation. If the tire element shows any signs of damage, it should be replaced immediately to prevent failure of the coupling and potential damage to the connected machinery. Additionally, the connecting fasteners should be checked periodically to ensure they are tight and secure, as loose fasteners can lead to excessive vibration and premature wear of the tire element. Lubrication is generally not required for tire couplings, which further simplifies maintenance.

In recent years, advancements in materials science and manufacturing technology have led to improvements in the performance and durability of tire couplings. The development of new elastomeric materials with enhanced properties, such as improved heat resistance, wear resistance, and oil resistance, has expanded the range of applications for tire couplings. For example, the introduction of high-performance polyurethane materials has increased the torque capacity and service life of tire couplings, making them suitable for more heavy-duty applications. Additionally, advancements in manufacturing processes, such as precision molding and reinforced fabric layers, have improved the consistency and reliability of tire coupling components. These advancements have made tire couplings an even more attractive option for industrial applications, offering a balance of performance, reliability, and cost-effectiveness that is difficult to match with other coupling types.

In conclusion, tire couplings are a versatile and essential component in industrial power transmission systems, offering a unique combination of flexibility, shock absorption, and ease of maintenance. Their simple yet effective design, based on an elastomeric tire element, allows them to compensate for shaft misalignments, absorb vibrations, and protect machinery from shock loads. While they have certain limitations in terms of torque capacity, operating temperature, and speed, their advantages make them suitable for a wide range of applications across various industrial sectors. Proper selection of tire couplings based on application requirements, along with regular maintenance, ensures their optimal performance and longevity. As materials and manufacturing technologies continue to advance, tire couplings are likely to play an even more important role in industrial power transmission, providing reliable and cost-effective solutions for the challenges of modern industrial operations.

« Tire Couplings » Update Date: 2026/1/10

URL: https://m.rokee.com/tags/tire-couplings.html