Rokee is a chinese Rubber Flexible Couplings Manufacturer, provide Rubber Flexible Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Rubber Flexible Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Rubber Flexible Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

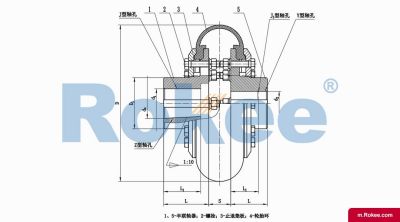

LLA Tyre Coupling

The LLA Tyre Coupling uses two semi-couplings to connect both sides of the elastic tyre body through internal pressing plates and bolts, making it easy to replace the elastic tyre body. The LLA Tyre Coupling is a kind of high elastic coupling, with good damping buffer and superior offset compensation performance.The working temperature of 20~80 degrees Celsius, transmitting torque 10~20000NM, suitable for damp, dust, shock, vibration, reversing the changeable and frequent starting working conditions, and convenient assembly and disassembly, no lubrication, durable and reliable. Non standard couplings are made in accordance with special needs. In overloading work and half coupling, there will be no malignant accidents.View More -

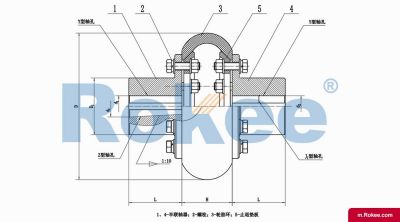

LLB Tyre Coupling

The LLB Tyre Coupling is a kind of high elastic coupling, with good damping buffer and superior offset compensation performance. The working temperature of 20~80 degrees Celsius, transmitting torque 10~20000NM, suitable for damp, dust, shock, vibration, reversing the changeable and frequent starting working conditions, and convenient assembly and disassembly, no lubrication, durable and reliable. Non standard couplings are made in accordance with special needs. In overloading work and half coupling, there will be no malignant accidents.View More -

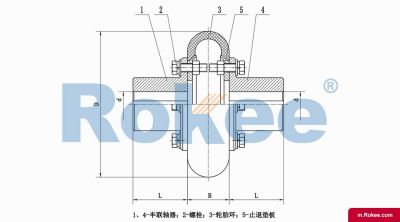

UL Tyre Coupling

UL Tyre Coupling adopts the structure of vulcanizing and bonding the tyre body with the metal connecting plate with threaded holes, which is then directly connected to the two semi-couplings by bolts for torque transmission and other displacement compensation.UL Tyre Couplings are flexible shaft coupling. UL type tire has good buffering performance. Operating temperature: -20~+80℃. Torque range: 10~25000N.M.UL Tyre Coupling mainly used in damp, dusty, vibration working environment. Because the elastic part is the whole tire, so, easy to disassemble and assemble. No lubrication is required.View More

Rubber flexible coupling is a mechanical transmission device with rubber elastic elements as the core components, and belongs to an important branch of flexible couplings with elastic elements. It effectively compensates for axial, radial, and angular offsets between two shafts while transmitting torque through the high elastic deformation ability of rubber materials, and significantly reduces vibration and impact.

Typical structural composition

Metal connector: a main and secondary end flange usually made of cast iron or aluminum alloy material, connected to the shaft through keyway or bolt

Rubber elastomer: designed with a polygonal (6-angle or 8-angle) cross-section, bonded to metal parts through vulcanization process

Protection mechanism: V-shaped section protection ring design to prevent rubber from being damaged due to excessive deformation

Pre compression structure: Ensuring transmission stability through radial bolt pre tightening

Rubber components achieve displacement compensation through three deformation modes:

Shear deformation: cope with radial offset (up to ± 1.5mm)

Compression deformation: absorbs axial displacement (± 3mm)

Twisted deformation: Adjust angular deviation (± 4 °)

The high damping characteristics of rubber can absorb system vibration energy and reduce the transmission of impact loads by 15% -20%. Experimental data shows that its vibration reduction effect is more than three times higher than that of a non elastic component coupling.

Main types and application comparison

Compression type rubber coupling

Plum shaped elastic coupling: transmits torque through compression of convex claws and rubber pads, suitable for pumps and fans with moderate loads (<5000N · m)

Rubber sleeve column pin coupling: The column pin is covered with a rubber sleeve, with a compensation capacity of ± 1.2mm radial offset, and is commonly used in textile machineryShear type rubber coupling

Tire type coupling: Full rubber ring structure with angular compensation of up to 5 °, specifically designed for difficult installation and alignment of heavy equipment

Rubber metal ring coupling: metal ring and rubber are alternately laminated, with adjustable torsional stiffness, suitable for precision servo systems

« Rubber Flexible Couplings » Post Date: 2024/5/6

URL: https://m.rokee.com/tags/rubber-flexible-couplings.html