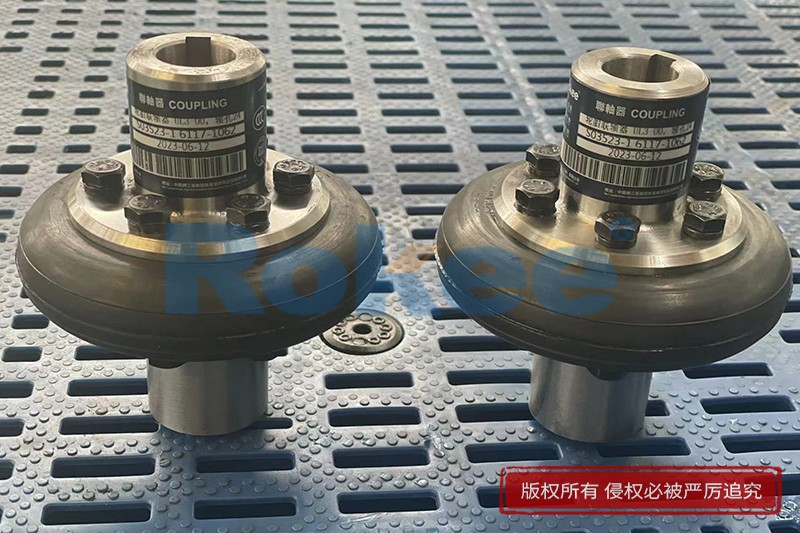

Rokee® Customized UL3 Tire Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

The UL tire coupling adopts an innovative composite structure design, perfectly integrating the strength of metal and the elasticity of rubber. Its core consists of three parts: two precision machined metal flanges (usually made of 45 # steel forgings) and an integral rubber tire body. The tire body, as the "heart" of the coupling, is made of high-quality rubber material and embedded with nylon thread and nylon cloth reinforcement layer through special technology. This unique reinforcement structure enhances its fatigue resistance by more than three times compared to ordinary rubber, significantly extending its service life.

Connection mechanism: The inner side of the tire ring is firmly bonded to the steel frame through vulcanization process, and high-strength nuts are welded on the frame. During assembly, the tire body and the flanges of the two half couplings are tightened by pre tightening bolts, and torque is transmitted through end face friction. This connection method ensures sufficient torque transmission capability while retaining necessary elasticity.

Displacement compensation principle: When the system is running, the tire ring undergoes three-dimensional elastic deformation - radial deviation causes bending deformation, axial deviation causes tensile/compressive deformation, and angular deviation forms conical deformation. Test data shows that its compensation capability can reach 2mm in the radial direction, 5mm in the axial direction, and 1 ° in the angular direction, far exceeding most rigid couplings.

Dynamic response characteristics: The viscoelastic behavior of rubber materials makes them a natural vibration filter that can absorb up to 30% of impact energy. In the application of metallurgical rolling mills, this characteristic can reduce the vibration amplitude of the transmission system by more than 60%, effectively protecting the gearbox and motor bearings.

The high elastic deformation characteristics of rubber tire bodies make them ideal vibration absorbers. Laboratory data shows that under the same impact load, the vibration energy transmitted from UL type couplings to the driven end is only one-third of that of toothed couplings. This characteristic is particularly prominent in metallurgical equipment (such as the moment of steel biting in a rolling mill) and mining machinery (when the hardness of the ore suddenly changes), which can effectively avoid resonance phenomena in the transmission chain and protect expensive equipment from impact damage.

Compared to traditional couplings that can only compensate for a single type of deviation, the UL type design achieves three-dimensional comprehensive compensation:

Axial compensation: up to 5mm, suitable for shaft system expansion and contraction caused by thermal expansion

Radial compensation: allowing a deviation of 2mm to solve the problem of foundation settlement

Angular compensation: 1 ° deflection capacity to overcome installation alignment errors

This compensation capability reduces installation and adjustment time by more than 50%, making it particularly suitable for long wheelbase and multi pivot transmission systems.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/ul3-tire-coupling.html