Rokee is a chinese Bushed Pin Couplings Manufacturer, provide Bushed Pin Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Bushed Pin Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Bushed Pin Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

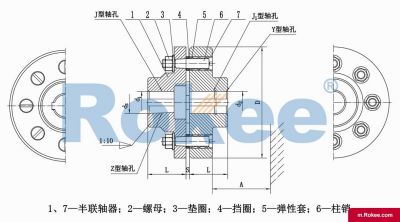

LT/TL Elastic Sleeve Pin Coupling

LT Elastic Sleeve Pin Coupling is the basic form of this series of couplings.View More -

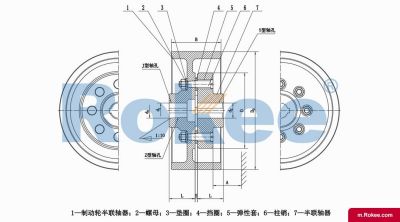

LTZ/TLL Elastic Sleeve Pin Coupling With Brake Wheel

LTZ Elastic Sleeve Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.View More

Structural composition

Flange type half coupling: Two symmetrical flanges with bolt holes, usually made of cast iron or steel material, with a surface precision machined to ensure the flatness of the contact surface.

Rubber lining: an elastic element nested in bolt holes, mostly made of oil resistant chloroprene rubber or polyurethane, with a hardness range of 60-80 Shore A, providing radial compression deformation space.

Column pin component: High strength alloy steel pin, chrome plated anti rust surface, connected to the two halves of the coupling through the bushing, allowing for slight sliding while transmitting torque.

Compensation mechanism

Axial displacement: The rubber liner can absorb an axial displacement of ± 1.5mm (such as thermal expansion difference) when subjected to compression deformation.

Radial offset: The lateral deformation of the liner adapts to radial deviations of ≤ 0.8mm (such as installation errors).

Angular deviation: Angle compensation within ± 1 ° is achieved through uneven compression of the lining (such as misalignment of the shaft system).

Torque transmission path

Drive shaft → flange half coupling → column pin squeezing rubber sleeve → driven side flange → driven shaft, vibration energy is converted into thermal energy dissipation by internal friction of rubber molecules.

Typical applications

Motor pump assembly: compensates for instantaneous alignment deviation during motor start-up to avoid bearing overload.

Conveyor Drive: Absorbs shaft displacement caused by chain tension and protects gearbox gears.

Ventilation system: isolate the vibration transmission caused by the unbalanced movement of the fan impeller.

« Bushed Pin Couplings » Post Date: 2024/5/5

URL: https://m.rokee.com/tags/bushed-pin-couplings.html