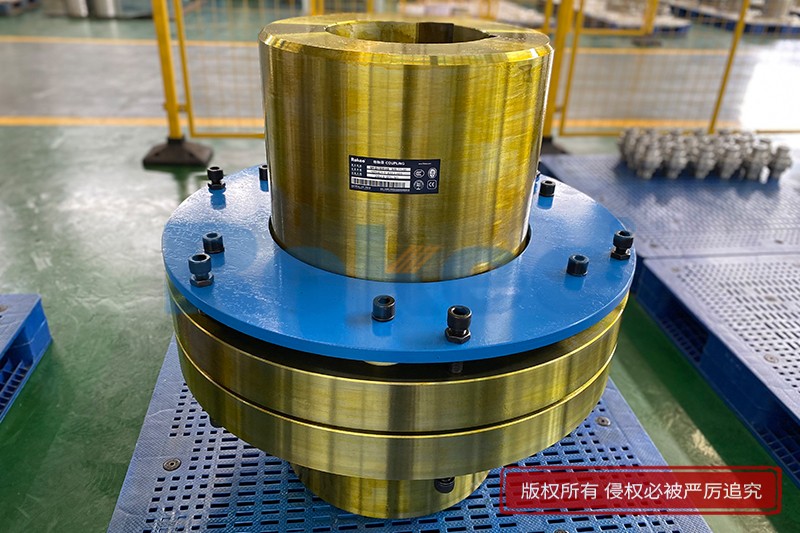

Rokee® Customized LT15 Pin Coupling With Elastic Sleeve for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

The LT elastic sleeve pin coupling is a non-metallic elastic element flexible coupling. The LT type coupling uses column pins with rubber or polyurethane sleeves to connect the two halves of the coupling, and transmits torque and compensates for axis deviation through the compression deformation of the elastic sleeve. This design does not require metal vulcanization bonding process, simplifies the manufacturing process, and makes it more convenient to replace elastic components. Compared to metal couplings, LT type has three major characteristics: lubrication free, vibration damping and buffering, and installation tolerance. Its structure is so simple that the elastic sleeve can be replaced by simply removing the baffle, and the maintenance time can be controlled within 30 minutes, greatly reducing equipment downtime losses.

The exquisite design of LT type elastic sleeve pin coupling is the key to its long-term market dominance. The coupling consists of three core components: two flanged metal half couplings (usually made of HT200 cast iron or ZG270-500 cast steel), multiple sets of column pin components (column pins+elastic sleeves), and a fixed baffle. One end of the column pin is fixed to a half coupling through interference fit, and the other end is fitted with an elastic sleeve made of rubber or polyurethane material, which is inserted into the corresponding hole of the other half coupling to form an elastic connection.

When the driving shaft rotates, the torque is transmitted through the contact friction and compression deformation between the pin group and the elastic sleeve. The specific process is as follows: the active side half coupling drives the column pin to rotate → the column pin squeezes the elastic sleeve → the deformation of the elastic sleeve drives the driven side half coupling to rotate. This dual transmission mechanism ensures the smoothness of power transmission, with a transmission efficiency of over 98%.

The coupling compensates for axis deviation through three-dimensional deformation of the elastic sleeve:

Radial compensation (≤ 0.5mm): lateral compression deformation of elastic sleeve in the hole

Axial compensation (≤ 3mm): Compression and tensile deformation of elastic sleeve

Angular compensation (≤ 1.5 °): The deflection of the pin in the hole causes the elastic sleeve to undergo conical deformation

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/lt15-pin-coupling-with-elastic-sleeve.html