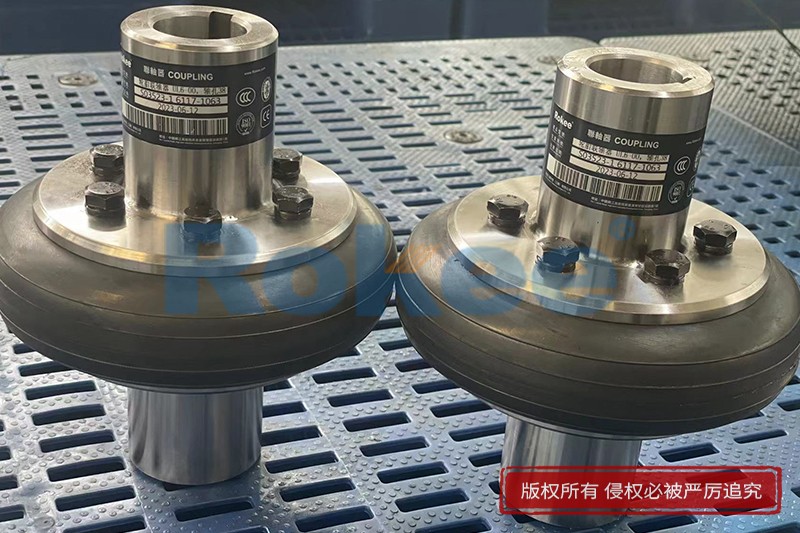

Rokee® Customized UL6 Tyre Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

UL tyre coupling is a highly elastic coupling that occupies an important position in the field of mechanical transmission due to its excellent shock absorption and buffering performance, as well as outstanding inter axis offset compensation capability. This type of coupling is designed for harsh working conditions and can operate stably within a temperature range of -20 ℃ to 80 ℃. It can transmit a wide range of torque, from 10N · m to 20000N · m, meeting different power transmission needs.

The core advantage of UL tire couplings lies in their maintenance free design - they do not require lubrication and are easy to disassemble, making them particularly suitable for working environments with high humidity, dust, and frequent impact vibrations. Compared with traditional metal couplings, it absorbs impact through the elastic deformation of rubber tire bodies, effectively reducing vibration and noise during equipment operation, and protecting the transmission system from damage. In industries such as metallurgy, mining, and lifting and conveying, this type of coupling has become an ideal choice for solving complex transmission problems.

The innovative structural design of UL tyre couplings is the foundation of their high performance. The coupling mainly consists of three parts: two metal flanges with shaft holes and an integral rubber tire body. The tire body is made of high-quality rubber material, with nylon thread and nylon cloth embedded inside as reinforcement layers. This composite structure ensures high elasticity and improves fatigue resistance, significantly extending the service life.

In terms of connection mechanism, the inner side of the tire ring is firmly bonded to the steel frame through vulcanization process, and nuts are welded on the frame. During assembly, the tire body is tightly connected to the flanges of the two half couplings using high-strength bolts, and torque is transmitted through end face friction. When the system is running, the tire ring undergoes torsional shear deformation, which not only transmits power but also effectively absorbs impact and vibration.

UL tire couplings have outstanding displacement compensation capabilities and can simultaneously handle multiple deviations:

Axial displacement: compensation capacity can reach 5mm

Radial displacement: allowable deviation within 2mm

Angular deviation: can adapt to deflection within 1 °

This all-round displacement compensation capability enables it to perform well in complex working conditions where installation accuracy is difficult to guarantee, greatly reducing installation difficulty and alignment requirements.

UL tyre couplings have multiple outstanding performance characteristics that make them stand out among numerous coupling types:

Shock absorption and buffering performance

The rubber tire body provides extremely high elastic damping, capable of absorbing up to 30% of impact loads and effectively isolating equipment vibrations. Tests have shown that it can reduce the vibration amplitude of the transmission system by more than 60%, making it particularly suitable for solving the impact problems caused by frequent start stop and variable forward and reverse rotation.Environmental adaptability

The rubber material with special formula is adopted, with wide temperature tolerance range (-20 ℃~80 ℃) and excellent anti-aging performance. Its sealing structure design can prevent moisture and dust from entering, and can maintain stable performance in harsh environments such as humidity and high dust. Its service life can usually reach more than 5 years.Maintenance simplicity

The integrated design makes the installation and disassembly process extremely simple, and there is no need to move the equipment axially when replacing the tire body. The feature of no lubrication eliminates lubricant contamination and the trouble of regular maintenance, reducing long-term usage costs.Security protection function

When the system experiences overload, the tire will absorb excess energy through elastic deformation, providing overload protection and avoiding damage to expensive equipment in the transmission chain.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/ul6-tyre-coupling.html