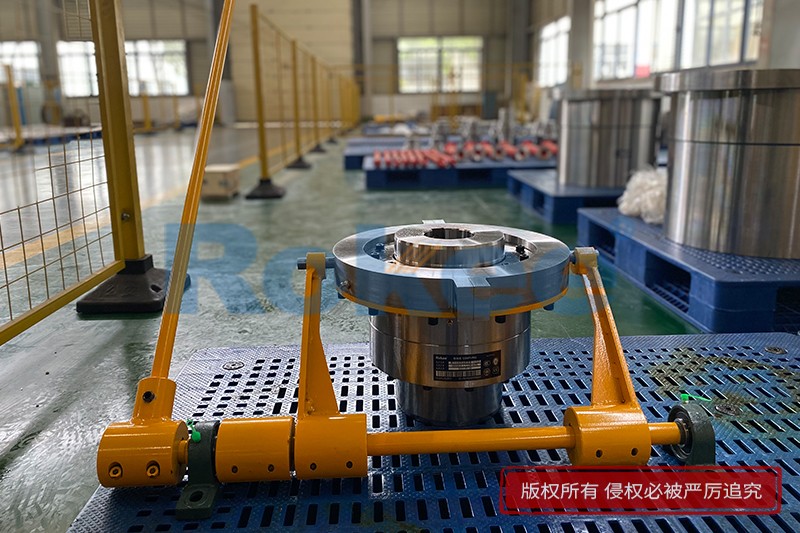

Rokee® Customized Fork Toothed Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

Fork toothed couplings as a special type of toothed coupling, play a crucial role in modern mechanical transmission systems. It cleverly combines the functions of the fork mechanism with the gear coupling, achieving more flexible and reliable torque transmission and clutch control.

Fork tooth coupling is a highly specialized coupling device in the field of mechanical transmission. It combines the torque transmission capability of traditional toothed couplings with the clutch control function of the fork mechanism, forming a unique structural system. This type of coupling mainly consists of two toothed half couplings, a fork assembly, a drum tooth meshing system, and necessary fixing components. Through precise mechanical cooperation, it achieves dual functions of power transmission and inter shaft displacement compensation. Compared with traditional couplings, fork toothed couplings not only have excellent load bearing characteristics, but also can achieve selective power connection and disconnection during system operation, greatly improving the operational flexibility and control accuracy of mechanical systems.

In terms of core working principle, the fork toothed coupling utilizes the meshing of inner and outer teeth to transmit torque and rotational motion. The external teeth are usually designed as a drum shaped tooth structure, with a spherical profile on the tooth surface and the center of the ball located on the gear axis. This design significantly increases the tooth flank clearance, allowing the coupling to tolerate larger angular deviations (usually up to 1.5 ° -6 °). At the same time, the contact conditions of drum shaped teeth are more superior, which can effectively reduce edge stress concentration, improve torque transmission efficiency and service life. As a characteristic component of the coupling, the fork mechanism controls the meshing and separation of the inner and outer teeth through mechanical or hydraulic means, achieving rapid connection and disconnection of the transmission system. This feature makes it an irreplaceable advantage in equipment that requires frequent start stop or working condition changes.

From the perspective of performance characteristics, the fork geared coupling exhibits multiple technological advantages. Its radial size is relatively compact, but it provides extremely high load-bearing capacity per unit volume, making it particularly suitable for heavy-duty applications with limited space. The comprehensive displacement compensation capability allowed by the coupling (including axial, radial, and angular deviations) significantly reduces installation accuracy requirements, while also reducing additional loads caused by misalignment. By optimizing the drum shaped tooth contact surface and continuous lubrication system, this type of coupling can maintain smooth operation under high-speed rotation conditions, and effectively control vibration and noise levels. It is worth mentioning that the introduction of the shift fork mechanism not only achieves controllable clutch function, but also facilitates system maintenance and repair, and key components can be inspected and replaced without the need for overall disassembly.

In industrial applications, fork toothed couplings are widely used in various heavy machinery and precision equipment due to their excellent adaptability. This type of coupling can be seen in hot rolling mills in the metallurgical industry, crushing systems in mining machinery, hoisting mechanisms in lifting equipment, and large compressors in the petrochemical industry. Especially in situations where frequent switching of power transmission states is required, such as the transmission system of cold-rolled strip mills, auxiliary drive devices of generator sets, etc., the fast and reliable clutch function provided by the fork toothed coupling makes it an ideal choice. With the development of modern mechanical systems towards high efficiency and intelligence, the design and manufacturing technology of fork toothed couplings are constantly advancing, providing solutions for more complex and demanding industrial applications.

The brilliance of the fork toothed coupling lies in its unique structural design, where each component is carefully calculated and configured to ensure the reliable performance of the coupling under complex working conditions. An in-depth analysis of the internal structure of this mechanical device can help us better understand its outstanding functional performance and wide applicability. The fork toothed coupling is not a simple combination of mechanical components, but a comprehensive system that integrates precision transmission and controllable clutch functions. Its structural design directly determines key performance indicators such as torque transmission efficiency, displacement compensation capability, and operational convenience.

In terms of core component composition, the fork gear coupling is usually composed of an active end half coupling, a driven end half coupling, a middle connecting sleeve, a sliding gear sleeve, a fork mechanism, and a lubrication and sealing system. The active and passive half couplings are fixedly connected to the drive shaft and the driven shaft through keyway or interference fit, forming the basic path for torque transmission. The joint end face of the two half couplings is machined with precision inner or outer teeth, and the tooth profile is usually involute profile and specially hardened to improve wear resistance. The middle connecting sleeve, as a bridge component, is equipped with a tooth groove structure that matches the half coupling inside. Under the action of the fork mechanism, it can slide axially to achieve precise control of the meshing state. Sliding gear sleeve is a key moving component of the coupling, which is mechanically connected to the fork mechanism and can move axially under the action of operating force to complete the engagement or disengagement with the half coupling tooth surface. As the control core, the fork mechanism has various design forms, including manual lever mechanism, hydraulic piston mechanism, or electromagnetic drive device, which can be selected according to different application scenarios and control requirements.

The drum shaped tooth design is the technical essence of the fork gear coupling. Compared with ordinary straight tooth couplings, the tooth surface of drum shaped teeth is raised in a circular arc shape, similar to a barrel shaped structure. This geometric feature brings multiple performance advantages. The contact area of the drum shaped teeth dynamically changes with the operation of the coupling, avoiding local stress concentration and making the load distribution more uniform. When there is an angular deviation between the two axes, the spherical characteristics of the drum shaped teeth can adaptively adjust the contact position, maintain sufficient meshing area, and avoid edge contact or even jamming like straight teeth.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/fork-toothed-coupling.html