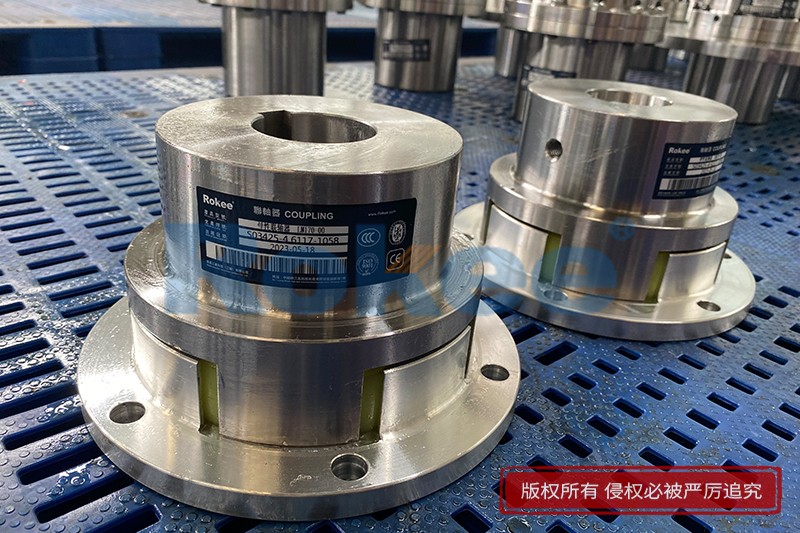

Rokee® Customized LM Flexible Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

LM flexible couplings as key components in mechanical transmission systems, play an important role in modern industrial equipment. This type of coupling, with its unique structural design and material characteristics, can effectively solve various deviation problems in shaft connections, while providing buffering and vibration reduction functions to protect the transmission system from damage caused by impact loads.

LM flexible coupling is a type of mechanical transmission device that connects shafts through elastic elements and is an important member of the flexible coupling family. The model identification "LM" usually represents a specific series of plum blossom shaped elastic couplings, which have formed a standardized product series in the industrial field. This type of coupling compensates for various deviations between shaft systems through the deformation ability of elastic bodies, while transmitting torque and rotational motion.

The working principle of LM flexible coupling is based on the principle of elastic deformation. When the driving shaft transmits torque, the force is transmitted to the elastic element through the metal parts of the coupling, and the elastic body undergoes controllable deformation to transmit power to the driven shaft. During this process, the elastic element can absorb some vibration energy, compensate for axial, radial, and angular installation deviations, and effectively reduce the additional load on equipment bearings and other transmission components.

In terms of structural design, LM flexible coupling adopts a compact radial dimension design, with a simple and efficient overall structure. A typical structure consists of two metal flange disks and an elastic body, with convex teeth on the flange disks that transmit torque through radial compression of the elastic body. This design makes the coupling lightweight and has a small moment of inertia, making it particularly suitable for applications at medium to high speeds. The ML1 to ML13 series products cover different nominal torques and shaft hole parameters, and users can flexibly choose according to their needs. Some models such as MLS and MLPK adopt a separable structure design, allowing users to replace elastic components without moving the device, greatly simplifying maintenance work.

In terms of material application, the core of LM flexible couplings is elastic components, usually made of high-strength polyurethane materials that are wear-resistant and oil resistant. This material has excellent mechanical properties and durability, with high load-bearing capacity and long service life. Polyurethane elastomers also have safe and reliable electrical insulation properties, which are particularly important in certain special applications. Metal components are mostly made of 45 grade steel or aluminum alloy, which undergo precision machining and heat treatment to ensure sufficient strength and durability.

In terms of performance parameters, LM series couplings perform excellently. Its working environment has a wide temperature range, up to -35 ℃ to+80 ℃, suitable for various harsh working conditions. The range of nominal torque transmission varies from 25Nm to 12500Nm, meeting various needs from light to heavy equipment. The allowable speed range is up to 1500-15300r/min, covering the speed range of most industrial equipment. These parameters indicate that LM couplings have a wide range of applicability and reliability.

In terms of compensation capability, LM flexible couplings demonstrate excellent performance. It can simultaneously compensate for axial, radial, and angular displacements, effectively solving alignment problems caused by installation errors, thermal expansion of the shaft, or foundation settlement. The axial compensation can usually reach 0.5-5mm, the radial compensation is 1-8mm, and the angular compensation is 0.5-5 °. The specific values vary depending on the model. This multi-directional compensation capability significantly reduces installation accuracy requirements and minimizes vibration and wear caused by misalignment.

In terms of maintenance convenience, LM couplings are designed with thoughtful consideration. The product does not require lubrication, reducing daily maintenance workload and allowing for continuous long-term operation. The separable structure design makes the replacement of elastic components simple and fast, significantly reducing downtime and maintenance costs. The overall structure of the coupling is simple, with a low failure rate, further improving the overall reliability of the equipment.

Compared with other types of couplings, LM flexible couplings have significant advantages. Compared to rigid couplings, it can better absorb vibrations and compensate for deviations; Compared with gear couplings, it has a simpler structure and does not require lubrication; Compared with diaphragm couplings, it has higher torsional elasticity and buffering capacity. These characteristics make LM flexible couplings an ideal choice for applications with medium torque and medium high speed.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/lm-flexible-coupling.html