Rokee is a chinese Bush Pin Flexible Couplings Manufacturer, provide Bush Pin Flexible Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Bush Pin Flexible Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Bush Pin Flexible Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

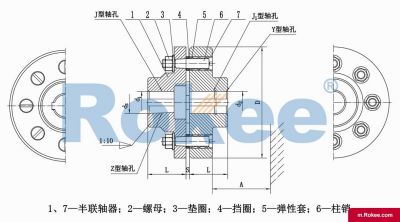

LT/TL Elastic Sleeve Pin Coupling

LT Elastic Sleeve Pin Coupling is the basic form of this series of couplings.View More -

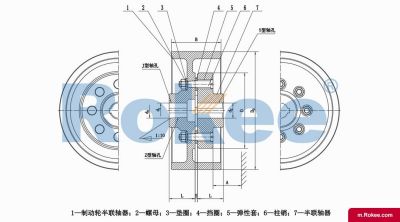

LTZ/TLL Elastic Sleeve Pin Coupling With Brake Wheel

LTZ Elastic Sleeve Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.View More

Bush Pin Flexible Coupling is a mechanical component mainly used to connect two shafts (driving shaft and driven shaft) in different mechanisms, so that they can rotate together to transmit torque. The elastic sleeve column pin coupling uses a column pin with an elastic sleeve (usually made of rubber material) on one end, which is installed in the flange hole of the two halves of the coupling to achieve the connection between the two halves of the coupling. This type of coupling has the characteristics of simple structure, easy installation, and easy replacement.

Characteristics:

Simple structure: The design of the Bush Pin Flexible Coupling is relatively simple, easy to manufacture and maintain.

Easy installation: Due to its compact structure, there is no need to move the two couplings during installation, making the installation process more convenient.

Easy to replace: When the elastic sleeve is worn or damaged, it can be easily replaced without disassembling the entire coupling.

Small size and light weight: Compared to other types of couplings, the Bush Pin Flexible Coupling has a smaller size and lighter weight, which is beneficial for reducing the overall weight of the equipment.

Application:

Bush Pin Flexible Couplings are widely used in various small and medium power transmission shaft systems, especially in scenarios driven by electric motors, with good base rigidity and precise alignment.

It is suitable for transmission systems with low impact loads that require buffering and shock absorption.

Working principle: The elastic sleeve will deform when compressed to compensate for the offset between the two axes and also serve as a shock absorber and buffer. Although this deformation amount is not large, it is sufficient to cope with common offset situations in small and medium power transmission shaft systems.

Performance:

The Bush Pin Flexible Coupling has a certain ability to compensate for shaft offset and can adapt to a certain degree of shaft misalignment.

It has buffering and shock-absorbing properties, which help reduce vibration and noise during the transmission process.

However, due to the appropriate clearance between the elastic sleeve and the pin hole, its cushioning and shock absorption performance is relatively limited.

Shortcoming:

Material issue: The traditional Bush Pin Flexible Coupling uses cast iron as the material, which is heavy and increases operating costs.

Difficulty in disassembly: When repairing water pumps and motors, it is relatively difficult to disassemble the Bush Pin Flexible Coupling, which can easily damage the coupling.

The requirement for relative radial displacement between the two axes is high, which increases the difficulty of aligning the concentricity of the coupling.

Improvement:

Replace cast iron with lighter materials to reduce weight and lower operating costs.

Optimize the design structure to make disassembly more convenient and reduce the risk of damage.

Improve adaptability to relative radial displacement between two axes and reduce the difficulty of finding concentricity.

There are various types and classifications of Bush Pin Flexible Couplings, such as LT type (formerly TL type), HL type, etc. Different types of couplings may vary in structure, performance, and application scenarios. Therefore, when choosing an Bush Pin Flexible Coupling, it is necessary to consider the specific usage needs and conditions comprehensively.

Bush Pin Flexible Coupling is a mechanical component with simple structure, easy installation, and wide application. Although there are some shortcomings, through continuous improvement and optimization of the design, its performance and application scope will be further enhanced and expanded.

In the realm of mechanical power transmission, couplings serve as indispensable components that bridge rotating shafts, enabling the seamless transfer of torque while accommodating inevitable misalignments and mitigating the adverse effects of vibrations and shock loads. Among the diverse array of coupling types available, the bush pin flexible coupling stands out for its simplicity, versatility, and cost-effectiveness, making it a preferred choice across numerous industrial sectors. This mechanical device, characterized by its robust yet flexible design, plays a critical role in ensuring the reliability and efficiency of countless machinery systems, from small-scale motors to large industrial equipment.

At its core, the bush pin flexible coupling consists of several key components that work in harmony to achieve its primary functions of torque transmission, misalignment compensation, and vibration damping. The fundamental structure comprises two flanged hubs, often referred to as semi-couplings, which are designed to be mounted on the ends of the shafts that need to be connected. One of these hubs is equipped with a series of cylindrical pins, typically made from high-tensile steel to ensure sufficient strength and durability. The corresponding hub features matching holes that are fitted with elastic bushes, which serve as the flexible interface between the pins and the hub. These bushes are usually constructed from elastomeric materials such as rubber, polyurethane, or neoprene, selected for their excellent resilience, vibration absorption capabilities, and resistance to wear and environmental factors. In some configurations, a spacer may be incorporated between the two flanges to accommodate larger shaft distances, a design particularly useful in applications such as pump drives where additional space between components is necessary. The spacer, often made from welded tubes with flanges, can be radially removed without dismantling the hubs from the shafts, simplifying maintenance procedures and minimizing downtime.

The working principle of the bush pin flexible coupling is both elegant and effective, leveraging the interaction between its rigid and flexible components to achieve smooth power transmission. When torque is applied to one of the connected shafts, it is first transferred to the associated hub. The pins attached to this hub then exert force on the elastic bushes fitted in the opposing hub. As the shafts rotate, the bushes compress and expand dynamically, allowing the pins to transmit torque to the second hub and subsequently to the connected shaft. This elastic deformation of the bushes is key to the coupling's ability to compensate for various types of shaft misalignment, including angular misalignment (where the shafts are not collinear but intersect at a point), parallel misalignment (where the shafts are parallel but offset), and axial misalignment (where the shafts experience end-to-end movement). Additionally, the elastomeric bushes act as a buffer, absorbing shock loads and dampening torsional vibrations that may arise from the operation of the machinery. By reducing the transmission of these vibrations to the connected components, the coupling helps to minimize wear and tear on bearings, gears, and other mechanical parts, thereby extending the overall lifespan of the equipment. Unlike some other coupling types, the bush pin flexible coupling operates without the need for lubrication, eliminating the risk of oil contamination in sensitive applications and simplifying maintenance requirements.

The selection of materials for the various components of the bush pin flexible coupling is a critical process that directly impacts its performance, durability, and suitability for specific applications. The flanged hubs, which bear the brunt of the torque and must maintain structural integrity under rotational stress, are typically manufactured from high-strength materials such as cast iron, cast steel, or ductile iron. Cast iron is a common choice for low to medium speed and torque applications due to its cost-effectiveness and good machinability, while cast steel or ductile iron are preferred for higher load conditions or applications requiring enhanced durability. The pins, responsible for transmitting torque from one hub to the other, are almost exclusively made from high-tensile steel, which offers exceptional strength and resistance to fatigue. Some specialized applications may utilize pins made from bronze or stainless steel to improve corrosion resistance in harsh environments.

The elastic bushes, being the heart of the coupling's flexibility and vibration damping capabilities, are selected based on a range of factors including the operating environment, temperature conditions, load requirements, and chemical exposure. Rubber is the most commonly used material for bushes due to its excellent damping properties, flexibility, and cost-effectiveness. Natural rubber is suitable for general-purpose applications, while synthetic rubbers such as nitrile rubber (NBR) are preferred for applications involving oil or fuel exposure, and neoprene offers enhanced resistance to ozone, weathering, and chemicals. Polyurethane bushes are another popular option, providing higher tensile strength and wear resistance than rubber, making them suitable for applications with higher loads or where longer service life is required. The choice of bush material also influences the operating temperature range of the coupling; for example, standard rubber bushes typically perform well between -20°C and 80°C, while specialized materials can extend this range to as low as -40°C or as high as 120°C for short-duration operations. All metal components, including the hubs and pins, are often coated with anti-corrosive agents to enhance their durability in harsh environmental conditions such as those encountered in marine, mining, or chemical processing industries.

The versatility of the bush pin flexible coupling is reflected in its wide range of applications across diverse industrial sectors, where it contributes to the reliable operation of various machinery systems. One of the most common applications is in pump drives, both horizontal and vertical configurations, where the coupling's ability to compensate for misalignment and dampen vibrations ensures optimal performance and prevents premature failure of pump components. In the materials handling industry, the coupling is extensively used in conveyor systems, where it connects motors to gearboxes and ensures the smooth transfer of torque required to move bulk materials such as coal, grain, or minerals. The robustness and low maintenance requirements of the bush pin flexible coupling make it particularly well-suited for this application, where machinery often operates continuously in harsh conditions.

The automotive and manufacturing sectors also benefit significantly from the use of bush pin flexible couplings. In automotive applications, they are used in drive shafts, gearboxes, and steering systems, where their vibration damping properties contribute to improved vehicle performance and driving comfort. In manufacturing facilities, the coupling is employed in a variety of machinery, including compressors, fans, ventilators, and textile machines. Fans and ventilators, in particular, rely on the coupling's smooth power transmission capabilities to maintain consistent airflow, while the absence of lubrication eliminates the risk of oil contamination in cleanroom environments often found in textile or pharmaceutical manufacturing. The construction industry utilizes the coupling in heavy-duty equipment such as cranes, excavators, and concrete mixers, where it withstands high loads and harsh working conditions to ensure the reliable operation of essential machinery. Similarly, in the mining industry, the coupling is used in crushers, conveyor systems, and other equipment exposed to extreme vibrations and heavy loads, thanks to its durable construction and ability to absorb shock.

The renewable energy sector is another area where the bush pin flexible coupling is gaining prominence, particularly in wind turbines and solar power plants. In wind turbines, the coupling connects the rotor shaft to the gearbox or generator, transmitting torque while accommodating misalignments caused by wind-induced vibrations and structural movement. The coupling's ability to withstand dynamic loads and torque variations is crucial for ensuring the efficient and reliable operation of wind energy systems. Additionally, the agricultural industry relies on the coupling for use in tractors, harvesters, and irrigation systems, where it enables the efficient transfer of power between shafts, facilitating mechanized farming processes and enhancing productivity.

Like any mechanical component, the bush pin flexible coupling has its inherent advantages and limitations, which must be carefully considered when selecting it for a specific application. One of the most significant advantages is its simplicity of design, which translates to ease of installation and maintenance. The coupling can be assembled and disassembled quickly without the need for specialized tools, and the wear elements (primarily the elastic bushes) can be easily replaced when they deteriorate, without requiring the removal of the entire coupling or the hubs from the shafts. This ease of maintenance minimizes downtime and reduces operational costs, a key consideration for industrial operations where continuous productivity is essential.

Another major advantage is the coupling's ability to dampen vibrations and absorb shock loads, which protects connected machinery components from excessive wear and extends their service life. The flexible nature of the coupling also allows for a certain degree of misalignment, eliminating the need for perfect shaft alignment during installation, which can be both time-consuming and costly. Additionally, the absence of lubrication requirements simplifies maintenance further, reduces the risk of oil leaks and contamination, and makes the coupling suitable for use in potentially explosive atmospheres where lubricant vapors could pose a hazard. The compact design of the bush pin flexible coupling allows it to be integrated into tight spaces, enhancing its versatility and suitability for applications with limited installation space. Furthermore, the coupling is cost-effective compared to other types of flexible couplings, making it an attractive option for budget-conscious operations without compromising on performance or reliability.

Despite its numerous advantages, the bush pin flexible coupling is not without limitations. One of the primary limitations is its relatively lower torque transmission capacity compared to rigid couplings such as gear or chain couplings. This makes it less suitable for high-torque applications, where alternative coupling types may be necessary to ensure safe and efficient operation. The operating speed of the bush pin flexible coupling is also lower than that of gear or chain couplings, primarily due to the flexible nature of the elastomeric bushes, which can experience excessive deformation at high speeds. As a result, it is typically recommended for low to medium speed applications, although specialized designs with high-strength materials can extend its speed range to some extent.

Another limitation is the susceptibility of the elastic bushes to wear and degradation over time, particularly in harsh operating environments involving high temperatures, chemical exposure, or continuous heavy loads. Regular inspection and replacement of the bushes are essential to prevent premature coupling failure and ensure continued reliability. The coupling is also sensitive to angular misalignment beyond a certain threshold; excessive misalignment can lead to increased wear on the bushes and pins, reducing the coupling's service life and potentially causing vibration transmission to connected components. Additionally, some configurations of the bush pin flexible coupling may exhibit slight circumferential backlash, which can reduce precision in applications requiring high positional accuracy, such as in robotics or precision manufacturing.

Proper installation, inspection, and maintenance are crucial for maximizing the performance and service life of the bush pin flexible coupling. During installation, it is essential to ensure that the shafts are aligned as accurately as possible, within the coupling's specified misalignment limits. This can be achieved using alignment tools such as dial indicators or laser alignment systems, which help to minimize excessive stress on the coupling components. The hubs should be securely fastened to the shafts using appropriate keys, set screws, or taper lock fitments to prevent slippage during operation. It is also important to ensure that the elastic bushes are correctly fitted into the hub holes and that the pins are properly inserted and secured, as loose components can lead to excessive vibration and premature wear.

Regular inspection is vital for detecting early signs of wear or damage. During inspections, particular attention should be paid to the elastic bushes, which are the most prone to wear. Signs of bush degradation include cracks, hardening, softening, or excessive wear on the inner or outer surfaces. The pins should also be inspected for signs of bending, corrosion, or wear, and the flanges should be checked for cracks or deformation. In applications involving harsh environments, more frequent inspections may be necessary to ensure that the anti-corrosive coatings on the metal components remain intact. Lubrication is generally not required for the bush pin flexible coupling, but it is important to keep the coupling clean and free from debris, which can accumulate and cause additional wear on the components.

When replacement of components is necessary, it is recommended to use replacement parts that match the original specifications to ensure compatibility and maintain the coupling's performance characteristics. The replacement of elastic bushes is a relatively straightforward process that can be completed without removing the hubs from the shafts, minimizing downtime. In cases where the pins or hubs are damaged, they should be replaced promptly to prevent further damage to the connected machinery. Additionally, when reassembling the coupling after maintenance or component replacement, it is important to ensure that any balancing marks are aligned correctly to retain the coupling's balancing qualities, which is particularly important for high-speed applications.

In conclusion, the bush pin flexible coupling is a versatile and reliable mechanical component that plays a vital role in power transmission systems across a wide range of industries. Its simple yet effective design, combining rigid metal components with elastic bushes, enables it to transmit torque efficiently while compensating for shaft misalignments and dampening vibrations. The careful selection of materials for its components ensures that it can be tailored to suit various operating conditions, from general-purpose applications to harsh environments involving high loads, extreme temperatures, or chemical exposure. While it has certain limitations, such as lower torque and speed capacities compared to some alternative coupling types, its numerous advantages—including ease of installation and maintenance, cost-effectiveness, and vibration damping capabilities—make it an indispensable choice for many industrial applications.

As industrial machinery continues to evolve, the bush pin flexible coupling is likely to remain a key component in power transmission systems, with ongoing advancements in material technology and design further enhancing its performance and expanding its range of applications. By understanding its design, working principle, and maintenance requirements, engineers and technicians can ensure that it is implemented effectively, contributing to the reliability, efficiency, and longevity of machinery systems. Whether in pump drives, conveyor systems, wind turbines, or automotive applications, the bush pin flexible coupling continues to demonstrate its value as a practical and efficient solution for connecting rotating shafts and transmitting power in a dynamic mechanical world.

« Bush Pin Flexible Couplings » Update Date: 2026/1/10

URL: https://m.rokee.com/tags/bush-pin-flexible-couplings.html