Rokee® Customized NL Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

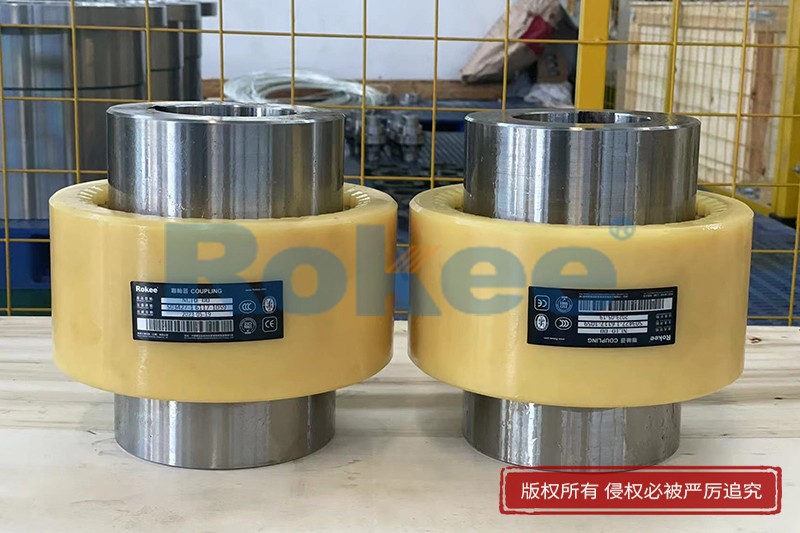

The NL coupling is mainly composed of nylon inner gear ring, outer gear shaft sleeve, half coupling, and connecting bolts. Among them, the nylon inner gear ring serves as the core component and is injection molded with a special formula of nylon material, which has good wear resistance, self-lubricating properties, and flexibility. The outer gear shaft sleeve is usually made of high-quality 45 # steel, which has undergone precision machining and heat treatment. The tooth surface has high hardness and good precision, and can perfectly mesh with the nylon inner gear ring. The half coupling is connected to the transmission shaft of the equipment through a key connection to achieve torque transmission. The connecting bolts are used to tightly connect the various components, ensuring the integrity and stability of the coupling during operation.

During operation, the half coupling at the active end drives the outer gear shaft sleeve to rotate, and the outer teeth on the outer gear shaft sleeve mesh with the inner teeth of the nylon inner gear ring, thereby transmitting torque to the half coupling and transmission shaft at the driven end. Nylon inner gear ring not only plays a role in transmitting torque, but also utilizes its own elastic deformation to effectively compensate for axial displacement, radial displacement, and angular displacement between the two shafts, reduce vibration and impact during equipment operation, and ensure the smoothness of transmission.

NL couplings are widely used in various industrial fields, such as chemical, food, pharmaceutical, automated production lines, etc. In the chemical industry, it is used to connect various pumps, mixers, and other equipment. Its buffering, vibration reduction, wear resistance, and self-lubricating performance can adapt to complex chemical production environments; In the food and pharmaceutical industry, due to its characteristics of no lubrication and no pollution, it is commonly used to connect food processing machinery and pharmaceutical equipment; In automated production lines, its high-precision torque transmission and good displacement compensation capability can ensure the precise operation of equipment.

When selecting, it is necessary to focus on parameters such as the maximum instantaneous torque of the transmission system, ambient temperature, and centering deviation. Ensure that the maximum instantaneous torque of the transmission system does not exceed a certain multiple of the nominal torque, the ambient temperature is within the working temperature range of the coupling, and the center deviation is controlled within a reasonable range to achieve a better service life.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.