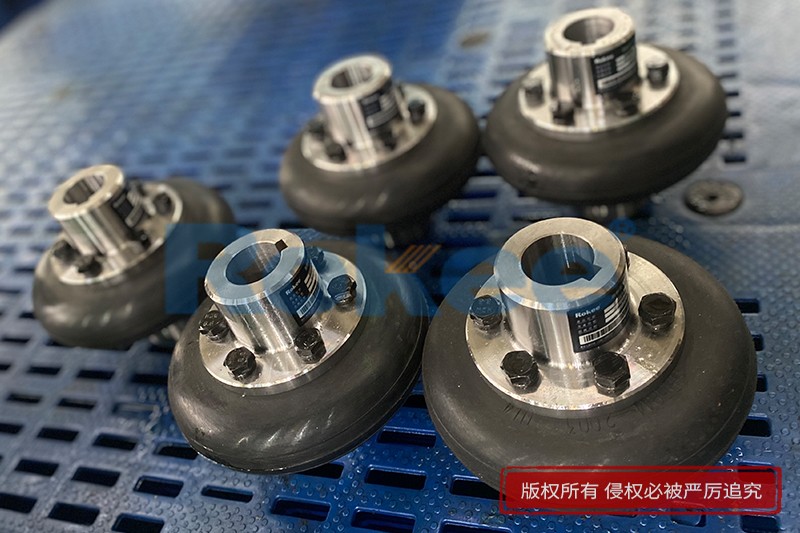

Rokee® Customized UL Flexible Tyre Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

As an important member of the tyre coupling family, UL flexible tyre couplings occupy an irreplaceable position in the industrial transmission field due to their unique rubber tire body design and excellent elastic compensation performance. This type of coupling is specifically designed for working conditions with frequent impact vibration, variable forward and reverse rotation, and frequent starting. It achieves torque transmission through high elastic rubber tire bodies while effectively absorbing system vibrations and compensating for shaft system deviations.

The UL flexible tyre coupling belongs to the high elasticity coupling category, and its core design concept is to achieve transmission connection through flexible rubber components, while providing multi-directional displacement compensation capability. Compared with ordinary rigid couplings, UL type has significant characteristics in structural innovation: the inner side of the tire ring is bonded to the steel skeleton through vulcanization process, and special nuts are welded at the bolt holes on the skeleton to form a sturdy composite structure. This design enables the coupling to possess both the strength of metal components and the elasticity of rubber materials, resulting in a more than 40% increase in shock absorption compared to traditional couplings with the same installation size.

From a specific structural perspective, the UL flexible tyre coupling consists of three key components:

Tire body: Made of high-quality rubber, nylon thread, and nylon cloth composite reinforcement material, with a thickness ranging from 13-50mm depending on the model, it is the elastic core of the coupling

Steel skeleton: usually made of 45 # steel or 42CrMo alloy steel, with a hardness of HB220-250 after quenching and tempering treatment, providing structural support

Connection components: including high-strength bolts and specially designed flanges, with bolt strength grades typically 8.8 or 10.9

The working principle of UL couplings is based on the elastic deformation of the tire body: when there is relative displacement between the two axes, the rubber tire body absorbs the deviation through shear deformation, while relying on the frictional force between the tire and the flange end face to transmit torque. Unlike ordinary couplings, the unique feature of UL type lies in its three-dimensional compensation ability - a single section structure can simultaneously handle axial (± 1.5% shaft diameter), radial (± 1% shaft diameter), and angular (1 ° -1.5 °) deviations, which makes it particularly outstanding in complex working conditions such as metallurgical equipment.

From the perspective of material technology, the manufacturing technology of modern UL flexible tyre couplings has made significant progress:

Rubber formula: Using a composite formula of natural rubber and synthetic rubber, the wear resistance index is three times higher than traditional materials

Enhancement technology: The internal nylon threads are arranged in a 45 ° cross pattern to form a three-dimensional mesh structure, increasing tear resistance by 60%

Sulfurization process: Adopting segmented temperature control vulcanization technology to achieve a bonding strength of over 8MPa between rubber and metal skeleton

It is worth noting that the main difference between UL type and similar products LLA type and LLB type is the tire body structure - the tire bodies of UL type and LLB type are designed without openings, while the LLA type is designed with openings. Under the same model, LLB tires have a thicker body and relatively higher load-bearing capacity than UL tires, but their compensation flexibility is slightly inferior. This difference makes UL type a better choice in applications that require balancing compensation capability and load-bearing performance.

UL flexible tyre couplings have demonstrated various technological advantages in the field of medium and low-speed heavy-duty transmission, making them an ideal choice to replace traditional gear couplings and diaphragm couplings. From the perspective of compensation capability, UL type couplings exhibit excellent multi-directional adaptability: axial compensation can reach ± 5mm to ± 50mm (depending on specifications), radial compensation is 0.4-6.3mm, and angular compensation is 1 ° -1 ° 30 ′. This all-round compensation capability is particularly suitable for large equipment with foundation settlement or thermal deformation. The measured data shows that the shaft alignment adjustment time can be shortened by more than 60% after the use of UL coupling.

In terms of dynamic performance, UL flexible tyre couplings have the following outstanding features:

Shock absorption and noise reduction: The damping characteristics of rubber tire body can reduce the system vibration amplitude by up to 70%, and reduce the noise level by more than 15dB (A)

Impact absorption: can effectively buffer instantaneous impact loads, with a peak torque reduction rate of 40-50%

Insulation performance: Rubber material provides electrical insulation with an insulation resistance of ≥ 100M Ω, suitable for transmission systems that require electrical isolation

Backlash free transmission: ensures precise speed transmission, with a transmission efficiency of up to 99.5%

The environmental adaptability of UL couplings is also commendable:

Temperature range: -20 ℃ to+80 ℃ (special formula can be extended to -40 ℃~+120 ℃)

Protective performance: Natural moisture resistance, dusty environment, no need for additional protection

Corrosion resistance: Stainless steel models can pass a 2000 hour salt spray test

Maintenance free design: No lubrication required throughout the entire lifecycle, reducing maintenance costs

Compared with similar products, the economic advantages of UL flexible tyre couplings are mainly reflected in three aspects:

Low installation cost: relatively relaxed requirements for alignment, saving over 40% of installation and adjustment time

Easy maintenance: No lubrication required, only need to check the bolt tightening status for daily use

Long lifespan: Under standard operating conditions, the service life can reach 5-8 years, which is 2-3 times longer than that of gear couplings

UL flexible tyre couplings have been widely used in many industrial fields due to their excellent impact resistance and inter axle deviation compensation capability. These application scenarios typically have common characteristics such as large load fluctuations, harsh environments, and high requirements for transmission stability, which perfectly leverage the technical advantages of UL type products.

Metallurgical equipment is the most representative application field of UL flexible tyre couplings. UL couplings exhibit game changing performance in equipment such as hot rolling mills, straightening machines, and coiling machines. The specific application advantages include:

Effectively absorb the impact load during the rolling process and protect the transmission system

Compensate for shaft displacement caused by roll adjustment and extend bearing life

Resistant to high temperature, water mist, and iron oxide scale environment in the rolling workshop

Reduce vibration transmission and improve the surface quality of the board

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/ul-flexible-tyre-coupling.html