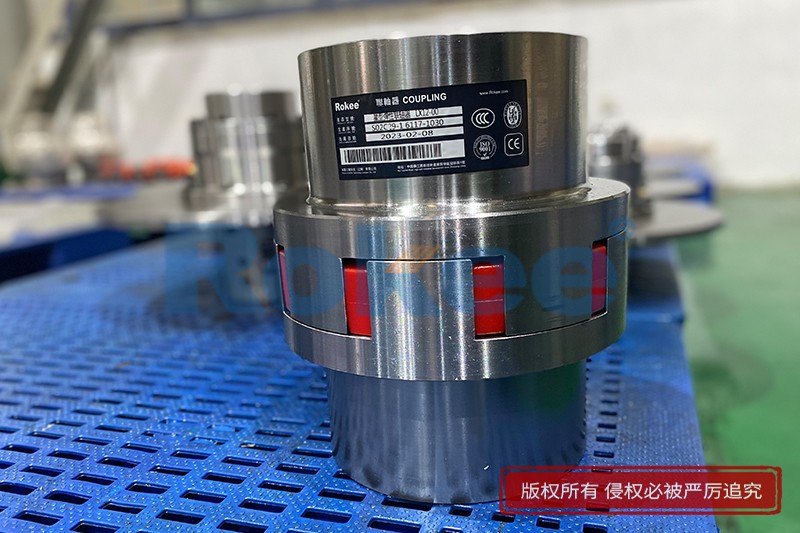

Rokee® Customized XL Flexible Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

The XL flexible coupling consists of two half couplings and a star shaped elastic body. Among them, the star shaped elastomer is usually made of polyurethane material, which has a radial star shape, and the central hole is matched with the convex claw of the half coupling. This structural design makes the XL flexible coupling simple, compact, and easy to install.

Performance Characteristics

Compensation capability: XL flexible couplings have the ability to compensate for relative offset between two shafts, including radial, angular, and axial offsets. This compensation capability enables it to cope with various displacements and deviations in mechanical transmission systems, ensuring the stability and reliability of the transmission.

Buffer and shock absorption: Due to the presence of star shaped elastomers, XL flexible couplings can absorb vibrations, reduce impact loads, and avoid shaft damage caused by rigid connections. This is of great significance for protecting transmission equipment and extending its service life.

Wear resistance: Polyurethane elastomer has good wear resistance, which enables XL flexible couplings to maintain stable performance during long-term use.

Applicable temperature range: The working temperature range of XL flexible coupling is -35 ℃ to+80 ℃, which can meet the needs of most mechanical transmission systems.

XL flexible couplings are suitable for connecting transmission shaft systems with two coaxial lines, such as motors, pumps, reducers, and other equipment. It is widely used in various mechanical transmission systems, especially in situations where displacement compensation, buffering and shock absorption, and wear resistance are required.

The model of XL flexible coupling is represented by "XL+number", where the number represents the specification, such as XL1, XL2 to XL12, etc. Different models correspond to different nominal torque, allowable speed, shaft hole diameter range, and structural dimensions. Users can choose the appropriate model and specifications according to their specific needs.

Precautions

When installing XL flexible couplings, it should be ensured that the fit tolerance between the shaft holes of the two half couplings and the shaft meets the standard to ensure the stability and reliability of the transmission.

During use, the wear of XL flexible couplings should be regularly checked, and severely worn elastic components should be replaced in a timely manner to ensure their long-term stable performance.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/xl-flexible-coupling.html