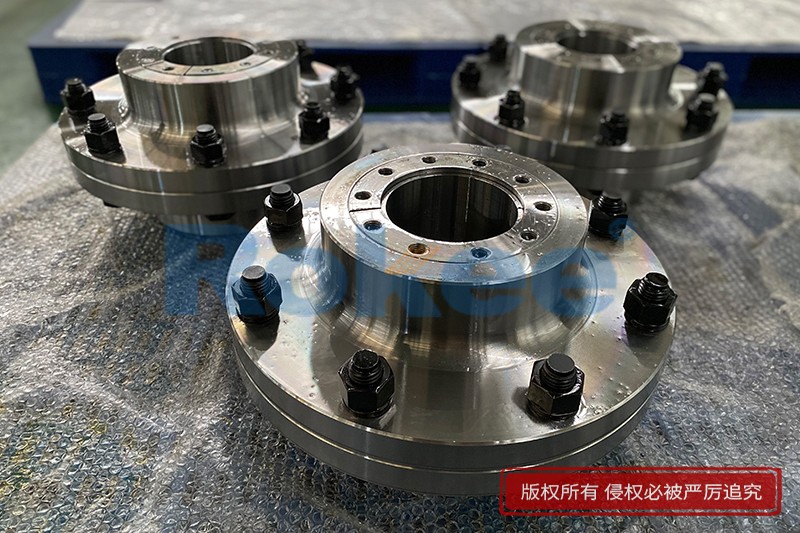

Rokee® Customized Expansion Sleeve Safety Couplings for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

The expansion sleeve safety coupling is an advanced mechanical component that combines the advantages of keyless connection of the expansion sleeve with the transmission function of the coupling, designed specifically for heavy loads and precision transmission needs. This type of coupling achieves a keyless connection between the shaft and the hub through the enormous clamping force generated by high-strength bolts, while also having multiple functions such as compensating for deviations, absorbing vibrations, and overload protection. In modern industrial transmission systems, the expansion sleeve safety coupling is gradually replacing traditional key connection couplings due to its unique performance advantages, becoming the preferred transmission solution in fields such as mining machinery, wind power generation, and CNC machine tools.

The expansion sleeve safety coupling mainly consists of the following key components:

Expansion sleeve component: usually composed of inner and outer conical rings, made of high-strength alloy steel such as 65Mn, 55Cr2, etc., which generates radial expansion force through bolt fastening

Coupling body: Depending on the type, it may include transmission components such as diaphragm groups, corrugated tubes, or plum blossom elastomers

High strength bolts: 12.9 grade bolts are used to generate necessary preload force, and some models adopt anti loosening nut design

Auxiliary components: including limit washers, rust proof seals

Taking the ZJM expansion sleeve diaphragm coupling as an example, its structure includes nine main components: stainless steel metal diaphragm group, half coupling, locking cover plate, Z1 type expansion sleeve, and clamping element. Through carefully designed mechanical cooperation, efficient transmission is achieved.

The working principle of the expansion sleeve safety coupling is divided into two key stages:

Connection phase:

The bolts are gradually tightened in diagonal order to generate axial tension

The relative motion between the inner and outer conical rings generates radial expansion force

The expansion sleeve forms extremely high contact pressure with the surface of the shaft and hub hole

Formation of static friction torque under the action of friction coefficient μTransmission stage:

The torque at the active end is transmitted to the input side of the coupling through the frictional force of the expansion sleeve

Elastic components such as diaphragms/bellows compensate for axial, radial, and angular deviations

Output torque from the driven end, while the elastic element absorbs vibration energy

When overloaded, the expansion sleeve generates relative sliding to achieve overload protection

Application scenarios

In the field of heavy industry:

Mining machinery: ball mill, crusher transmission system, needs to withstand impact loads

Metallurgical equipment: main drive of rolling mill, working temperature often reaches 200-300 ℃

Wind power generation: Yaw reducer, requiring a lifespan of 10 ^ 8 cyclesIn the field of precision machinery:

Numerical Control Machine Tool: Spindle Connection

Packaging machinery: servo drive system, starting and stopping more than 300 times per minute

Robot joint: Micro expansion sleeve coupling for collaborative robots

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/expansion-sleeve-safety-couplings.html