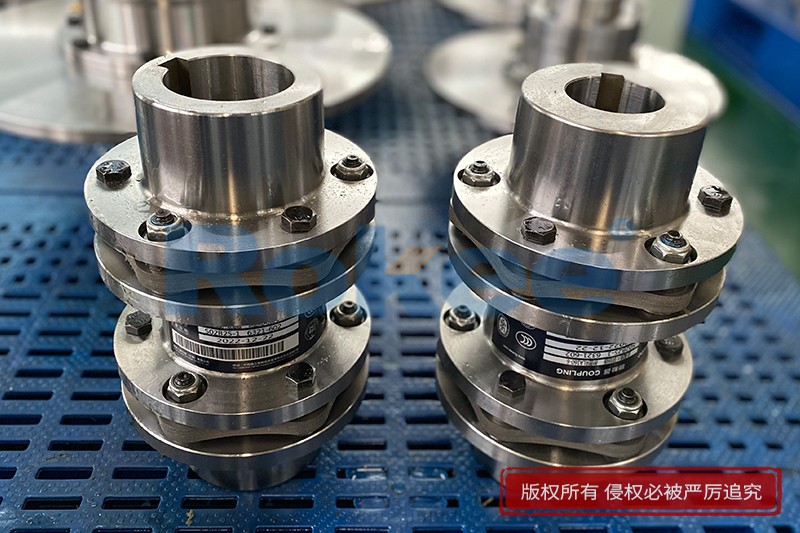

Rokee® Customized RLA Shim Pack Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

RLA shim pack coupling is a standard single group shim pack coupling, which belongs to the classic design of metal flexible couplings and is specially developed for medium and low-speed application scenarios. This type of coupling uses a single high-strength metal diaphragm as the core elastic element, which compensates for the relative displacement of the two shafts connected through the elastic deformation of the diaphragm. It has the characteristics of simple structure, good economy, and easy maintenance.

The RLA series shim pack coupling is independently developed by Rongji Industrial Technology (Jiangsu) Co., Ltd. based on high-quality product technology from Europe and Japan. Compared with traditional couplings, it has smaller volume, larger torque of the same type, and more reasonable proportioning size. The connection between the bolt and the diaphragm adopts a special elastic sleeve structure, which can significantly reduce the stress concentration at the hole edge, effectively prevent the diaphragm from tearing, and extend its service life.

The RLA shim pack coupling adopts a modular design, with simple assembly and quick maintenance and replacement. Its structural features include:

Single section design, compact structure

The volume is reduced by about 15% compared to similar products

The moment of inertia is reduced by about 20%

Using high-strength stainless steel membrane as the elastic element

The bolted connection adopts an elastic pad structure

Compared with traditional gear couplings, RLA shim pack couplings have several significant advantages:

Maintenance free design: No lubrication required, no worn parts

High precision transmission: zero backlash, able to accurately transmit speed

Strong environmental resistance: resistant to oil and corrosion, suitable for harsh working conditions

Vibration reduction and noise reduction: Stainless steel diaphragm can effectively absorb vibrations

Easy to install: compact structure, light weight, easy to assemble and disassemble

Main application scenarios

Pump equipment: various industrial process pumps, chemical pumps, boiler feed pumps, etc

Fan system: blower, ventilation equipment, compressor drive, etc

Power transmission: transmission system driven by electric motor and internal combustion engine

Heavy machinery: mining machines, coal mills, metallurgical equipment, etc

Turbomachinery: a medium low speed transmission system after deceleration

Industry Applications

Petrochemical industry: used for shaft connections of various pumps and compressors

Power industry: boiler feedwater pump, fan drive system

Metallurgical industry: Transmission of rolling mills and grinding equipment

Water treatment industry: large water pump drive connection

General Machinery: Various Industrial Transmission Systems

Installation precautions

Alignment requirement: RLA single section model cannot compensate for radial deviation, and accurate alignment of the two shafts must be ensured during installation

Bolt tightening: The bolts should be gradually tightened in diagonal order, using a torque wrench to achieve the specified torque

Axial clearance: Maintain appropriate axial clearance to avoid excessive axial force on the diaphragm

Protective measures: It is recommended to install protective covers around the coupling to ensure safety

Key points of maintenance and upkeep

Regular inspection: During the initial operation, all bolts should be checked for tightness and repeated several times to ensure that they are not loose

Diaphragm protection: Solid lubricants such as molybdenum disulfide can be applied between the diaphragms to reduce micro motion wear

Abnormal monitoring: If abnormal sound is found, the machine should be stopped immediately to check the installation accuracy and bolt status

Anti corrosion treatment: When used in corrosive environments, special coating treatment can be applied to the surface of the membrane

Selection considerations

Torque requirement: Select appropriate specifications based on the rated torque and peak torque of the transmission system

Speed range: Ensure that the working speed is within the allowable speed range of the coupling

Shaft diameter matching: When the shaft diameters of the master and slave ends are different, select the coupling model according to the larger shaft diameter

Deviation compensation: Evaluate the axial and angular deviations of the system and select models with appropriate compensation capabilities

Environmental conditions: Consider the impact of environmental factors such as temperature and corrosiveness on materials

Special Needs Solutions

Long distance transmission: RLAD standard double section shim pack coupling can be selected

High speed application: Consider RLHD high-speed shim pack coupling (with a speed of up to 42000rpm)

Space limited: RLAR single shaft sleeve reverse installation design is suitable for situations where the distance between the shaft head is limited

Large and small axis connection: RLAF model is suitable for situations where there is a significant difference in shaft diameter between the two ends

The RLA shim pack coupling has become an ideal choice for medium and low-speed transmission systems due to its simple structure, reliable performance, and easy maintenance. It perfectly combines the high strength of metal couplings and the deviation compensation ability of elastic components, demonstrating significant technological advantages in the field of industrial transmission. With the continuous advancement of technology and the accumulation of application experience, RLA shim pack couplings will play an important role in a wider range of industrial fields, providing efficient and reliable connection solutions for various rotating machinery.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/rla-shim-pack-coupling.html