Rokee is a chinese Jaw Flex Couplings Manufacturer, provide Jaw Flex Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Jaw Flex Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Jaw Flex Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

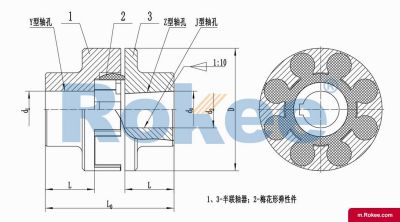

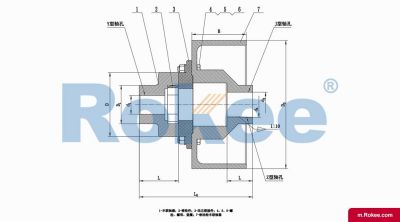

LM/ML Flexible Plum Jaw Coupling

LM Plum-shaped Flexible Coupling is the basic form of this series of couplings.View More -

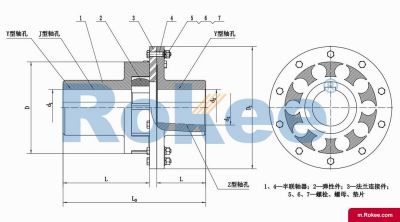

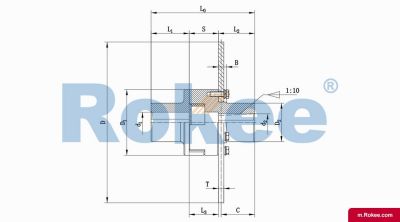

LMD/MLZ Flexible Plum Jaw Coupling With Single Flange

LMD Plum-shaped Flexible Coupling is added with transition connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View More -

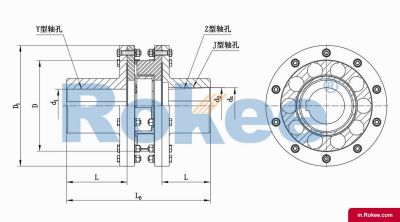

LMS/MLS Flexible Plum Jaw Coupling With Double Flange

LMS Plum-shaped Flexible Coupling adopts double transition flange connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View More -

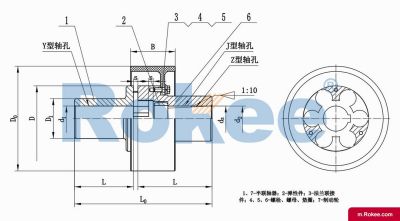

LMZ-I/MLL-I Flexible Plum Jaw Coupling With Split Brake Wheel

LMZ-I Plum-shaped Flexible Coupling adopts split brake wheel design, suitable for situations where braking is required.View More -

LMZ-II/MLL-II Flexible Plum Jaw Coupling With Integral Brake Wheel

LMZ- II Plum-shaped Flexible Coupling adopts integral brake wheel design, suitable for situations where braking is required.View More -

LMPK/MLPK Flexible Plum Jaw Coupling With Split Brake Disc

LMPK Plum-shaped Flexible Coupling adopts split brake disc design, suitable for situations where braking is required and eliminating the need of axially moving the semi-coupling when replacing the elastomer.View More

Jaw Flex Coupling is a special mechanical transmission device mainly used to compensate for the relative displacement between two shafts, while also having the functions of buffering and vibration reduction.

Jaw Flex Couplings can effectively absorb and adjust axial, radial, or angular offsets between two shafts through their special internal structural design. This type of coupling typically includes a series of elastic elements (such as elastic blocks, elastic pins, etc.) or mechanical structures (such as sliders, gear rings, etc.) that can deform when subjected to external forces, thereby compensating for the offset between the two shafts.

Jaw Flex Couplings can be classified into various types based on their structural design and working principles, such as claw type elastic couplings, claw type slider couplings, etc. These types have their own characteristics and are suitable for different working conditions and needs.

Claw type elastic coupling: small size, light weight, simple structure, easy installation, and low price. Commonly used in low-power and unimportant situations.

Claw type slider coupling: compensates for radial offset through slider structure, suitable for transmission systems that require compensation for large radial offsets.

Jaw Flex Couplings are widely used in various transmission systems with axial, radial, or angular offsets, especially in working conditions with stable loads and minimal impact. Its application scenarios include but are not limited to:

Shaft connections in heavy equipment such as steel mills and cement machinery.

Deep sea drilling equipment, lifting and deceleration equipment, woodworking equipment, machine tool equipment, petroleum equipment, textile equipment, etc. require high-precision and high load capacity transmission systems.

Advantages and Functions

Displacement compensation capability: Jaw Flex Couplings can effectively compensate for various offsets between two shafts, ensuring the stable operation of the transmission system.

Vibration control capability: Partial Jaw Flex Couplings (such as those with elastic elements) can reduce the vibration amplitude of the transmission system and improve the smooth operation of the equipment.

High load operation capability: Jaw Flex Couplings have the ability to adapt to high load operation in different environments, and can maintain excellent mechanical performance and service life under harsh conditions such as humid and hot environments and low temperatures.

Easy to install and maintain: The Jaw Flex Coupling has a simple structure, easy installation, and low maintenance costs.

In order to ensure the long-term stable operation of the Jaw Flex Coupling, regular maintenance and upkeep are required. This includes checking the wear of the coupling, replacing damaged elastic components or mechanical structures, adjusting the alignment accuracy of the coupling, etc. At the same time, it is also necessary to pay attention to keeping the transmission system clean and lubricated to avoid debris entering the interior of the coupling and causing damage.

Jaw Flex Coupling is a powerful and widely used mechanical transmission device. When selecting and using, appropriate selection and maintenance work should be carried out according to specific working conditions and needs.

« Jaw Flex Couplings » Post Date: 2024/5/8

URL: https://m.rokee.com/tags/jaw-flex-couplings.html