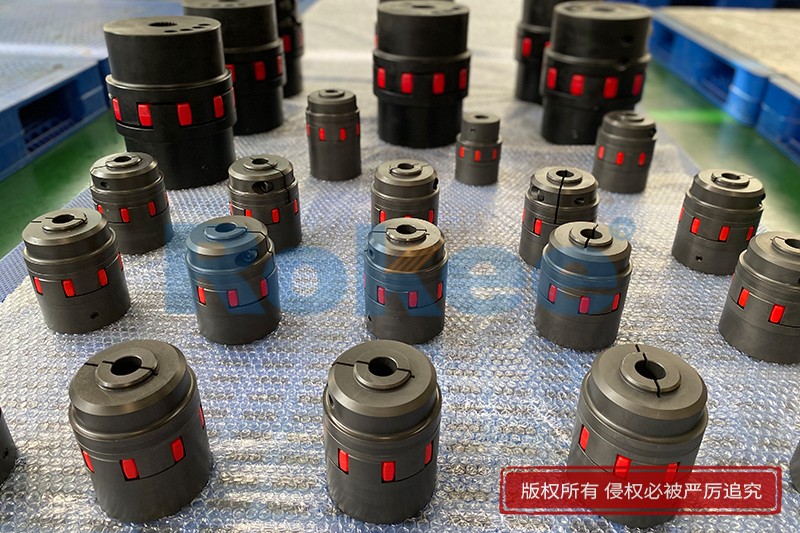

Rokee® Customized XL Star Couplings for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

The XL star shaped coupling as a high-performance elastic coupling, plays a crucial role in modern mechanical transmission systems. It cleverly combines the structural strength of claw couplings with the buffering performance of elastic elements, and is widely used in various mechanical transmission fields from precision servo systems to heavy industrial equipment.

XL star shaped coupling is a high-performance coupling device that uses engineering plastics as elastic elements, designed specifically for connecting two coaxial transmission shafts. This type of coupling achieves a perfect combination of torque transmission and deviation compensation through a unique combination structure of claw shaped protrusions and elastic bodies.

The core structure of this coupling consists of three parts: two metal claw discs with protruding teeth and a plum blossom shaped elastic body. Metal claw plates are usually made of high-quality 45 steel through heat treatment, with a hardness of HRC28-32, ensuring structural stability under high torque; The elastic element in the middle is mostly made of polyurethane material, with adjustable Shore hardness in the range of 75A-95A, and excellent mechanical strength and wear resistance. The specially formulated elastomer can also withstand a temperature range of -35 ℃ to+80 ℃, and some high-temperature resistant models can even withstand extreme working conditions of 120 ℃ in a short period of time.

The most prominent technical advantages of XL star shaped couplings are reflected in three aspects: firstly, it adopts a connection method without backlash under prestress, which is particularly suitable for applications such as spindle transmission, lifting platforms, and CNC machine tools that require high transmission accuracy; Secondly, the elastic components of the coupling mainly bear compressive stress rather than shear stress during operation, and the compressive strength of materials such as polyurethane is usually 3-5 times the tensile strength, which greatly improves the bearing capacity and service life of the coupling; Finally, its structural design allows for the replacement of elastic elements without moving the half coupling, overcoming the inconvenience of traditional plum blossom couplings in maintenance.

Compared with similar products, XL star shaped couplings exhibit significant performance advantages. It can compensate for axial displacement of 1-5mm, radial displacement of 0.5-3mm, and angular deviation of 1-5 °. This multi-directional compensation capability significantly reduces the installation accuracy requirements. Actual test data shows that using XL star shaped couplings can relax the centering accuracy requirement from 0.05mm for rigid couplings to 0.2mm, significantly reducing installation difficulty and time costs. At the same time, its elastic element is equivalent to a damping spring system, which can effectively absorb and attenuate 30% -50% of the vibration energy in the transmission system, especially suitable for situations with periodic impact loads.

XL star shaped couplings have developed multiple product series based on application scenarios and performance requirements to meet the needs of different industrial fields. The standard XL series is the most basic model, adopting a single flange design, suitable for most conventional transmission occasions; The XLS series adopts a double flange structure, which facilitates the replacement of elastic components without moving the equipment, and is particularly suitable for maintenance in situations with limited space; The XLL series is equipped with an extended intermediate sleeve, suitable for transmission systems with large shaft spacing; The XLP series integrates brake disc function and is commonly used in lifting equipment and lifting platforms that require quick braking. In addition, there are special models such as anti-static and corrosion-resistant, which meet the needs of special industries such as chemical and pharmaceutical industries.

In terms of maintenance, the XL star shaped coupling is designed to be maintenance free, but regular inspections are still necessary. It is recommended to conduct a comprehensive inspection every 2000 hours or half a year, focusing on whether the elastic body has cracks, hardening, or permanent deformation (if it exceeds 10% of the original thickness, it needs to be replaced), and whether the metal claws are worn or corroded. When replacing the elastomer, special tools should be used to avoid rough disassembly that may cause damage to the claw teeth. In environments with high levels of dust, protective covers can be installed to prevent abrasive particles from entering the meshing area. Proper selection, installation, and maintenance can extend the service life of XL star couplings to 8-10 years.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/xl-star-couplings.html