Rokee® Customized Elastic Claw Couplings for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

The elastic claw coupling, as a key component of modern mechanical transmission systems, plays a crucial role in the industrial field. This type of coupling, with its unique structure and performance advantages, is widely used in various mechanical transmissions from precision servo systems to heavy industrial equipment.

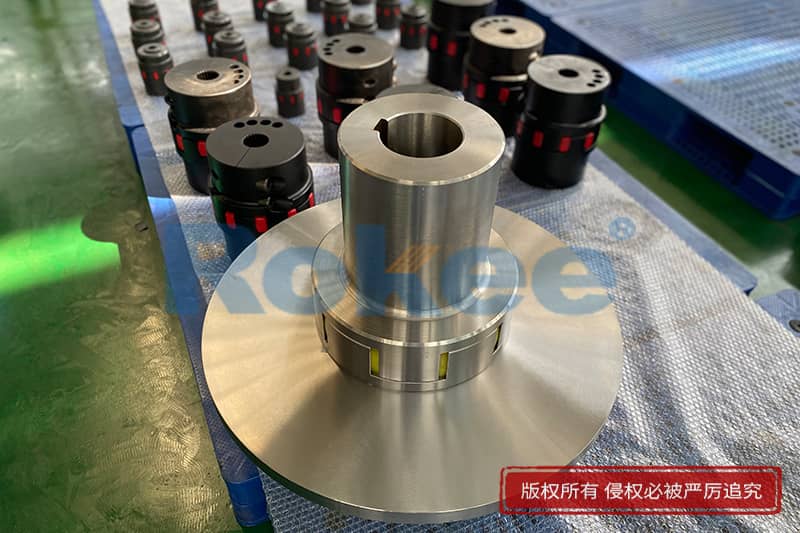

Elastic claw coupling is a flexible coupling device that uses elastic elements to achieve power transmission and compensate for shaft system deviations. Its basic structure consists of two metal claw disks and an elastic body, which utilizes the deformation ability of the intermediate elastic body to absorb and compensate for various deviations between the shaft systems. In the process of transmitting torque, the elastic element of this coupling mainly bears compressive force rather than rotational torque, which makes it have a longer service life and more stable transmission performance.

Compared with traditional rigid couplings, elastic claw couplings have significant technical advantages. It can not only effectively compensate for axial, radial, and angular deviations (usually axial displacement can reach 0.5-3mm, radial displacement 1-5mm, angular displacement 1 ° -5 °), but also reduce vibration and impact, protecting the transmission system from dynamic load damage. In addition, its characteristics of no lubrication and easy maintenance greatly reduce the cost of use. Compared with other flexible couplings such as gear couplings and diaphragm couplings, claw couplings have the advantages of simpler structure, more economical price, and easier installation, especially in small and medium power transmission systems.

The core design of the elastic claw coupling is based on three main components: two metal claw discs with convex teeth and a plum blossom shaped elastic element located in the middle. Metal claw plates are usually made of high-quality 45 steel through heat treatment, with a Rockwell hardness of HRC28-32. In situations where lightweight or load sensitivity is required, aluminum alloy materials (such as 6061-T6) are also used, with a density of only about one-third of steel. The number of convex teeth on the claw plate is commonly 4, 6, 8, or 10, and the tooth profile accuracy can reach IT7 level through precision milling or casting. The middle elastomer is mostly made of polyurethane material, with a Shore hardness usually between 75A-95A, which has excellent mechanical strength and wear resistance. Some special formulations can also withstand high temperatures up to 120 ℃ (in a short period of time).

The torque transmission mechanism of the coupling is very unique: when the driving shaft rotates, the convex teeth of the driving side claw plate squeeze the petals of the elastic body, and the force is transmitted to the convex teeth of the driven side claw plate through the deformation of the elastic body. This design allows the elastic body to mainly withstand compressive stress rather than shear stress during operation, while the compressive strength of elastic materials such as polyurethane is usually 3-5 times the tensile strength, greatly improving the bearing capacity and service life of the coupling.

In terms of deviation compensation, the elastic claw coupling exhibits excellent multi-directional compensation capability. When there is relative displacement between the two axes, the elastic element will undergo corresponding deformation: axial displacement causes the elastic body to be compressed or stretched; Radial displacement causes one side of the elastic body to be compressed while the other side relaxes; Angular deviation causes the elastic body to undergo conical deformation. High quality couplings can compensate for axial displacement of 1-5mm, radial displacement of 0.5-3mm, and angular deviation of 1-3 °. This compensation capability significantly reduces the accuracy requirements for installation alignment. Tests have shown that using elastic claw couplings can relax the alignment accuracy requirements from 0.05mm for rigid couplings to 0.2mm, greatly reducing installation difficulty and time costs.

The dynamic characteristics of the elastic claw coupling are also worth paying attention to. The elastic element in the middle is equivalent to a damping spring system, which can effectively absorb and attenuate the vibration energy in the transmission system. Test data shows that this type of coupling can reduce system vibration amplitude by up to 30% -50%, making it particularly suitable for situations with periodic impact loads. At the same time, elastomers also have good electrical insulation properties, with insulation resistance usually exceeding 100M Ω, which can effectively prevent current from forming a circuit through the coupling and protect bearings from electrical corrosion damage. This characteristic makes it particularly suitable for use in transmission systems such as variable frequency motors that may generate shaft currents.

Elastic claw couplings can be classified into various types based on their structural and performance characteristics to meet the needs of different industrial application scenarios. According to the shape and layout of elastomers, they are mainly divided into two categories: standard plum blossom and star shaped. The elastic body of the plum blossom shaped elastic coupling (such as the ML series) is in a complete plum blossom shape, with a large meshing area with the claw plate, which can transmit greater torque (up to 25kN · m), and is commonly used in heavy-duty applications such as metallurgy and mining. The elastic body of star shaped couplings (such as LMS series) is arranged in a split star shape, with each valve working independently and stronger compensation for deviations (angular compensation can reach 5 °), making them more suitable for pumps, fans, and other equipment with large alignment errors.

According to different fixing methods, it can be divided into three types: top screw fixing type, clamping type, and keyway fixing type. The top screw fixed type (such as MLZ series) directly tightens the shaft surface through radial screws, which is easy to install but has a small torque transmission (usually<500N · m), suitable for small equipment with limited space. The clamping type (such as MLJ series) adopts a split sleeve and bolt clamping structure, which does not damage the shaft surface and can transmit moderate torque (500-5000N · m), and has become the mainstream choice in servo systems. Keyway fixed type (such as ML series) is connected by flat keys or semi-circular keys, with the strongest torque transmission capacity (>5kN · m), but requires high installation accuracy and is mostly used in large industrial machinery.

The elastic claw coupling has a series of outstanding performance characteristics, which make it occupy an important position in the field of industrial transmission. The torque transmission capability is the core indicator of the coupling. The nominal torque range of the standard plum blossom coupling is extremely wide, ranging from a minimum of 16N · m to a maximum of 25000N · m, covering various needs from micro motors to large industrial equipment. Taking the ML10 coupling as an example, its nominal torque is 1000N · m, the maximum torque can reach 2000N · m, and the instantaneous overload capacity can reach up to 3000N · m (duration<3 seconds). This overload capacity can effectively protect the transmission system from damage caused by accidental impact.

In terms of speed adaptability, the elastic claw coupling performs well. The allowable speed of standard models is usually between 1500-15300r/min, and specially designed high-speed models (such as MLS series) can even reach 30000r/min. It is worth noting that the rated speed of the coupling will decrease with the increase of operating temperature, for example, at an ambient temperature of 80 ℃, the allowable speed usually needs to be reduced by 20% -30%. The dynamic balance accuracy level of the coupling is generally G6.3, and the high-speed type can reach G2.5, ensuring that excessive centrifugal force is not generated during high-speed operation. Actual test data shows that a coupling with a diameter of 200mm can reduce the additional bearing load by more than 50% when the unbalance is controlled within 5g · mm at a speed of 10000r/min.

Environmental adaptability is an important aspect of measuring the performance of couplings. The working temperature range of standard polyurethane elastomers is -35 ℃ to+80 ℃, while elastomers with special formulations (such as silicone rubber) can extend the temperature range to -50 ℃~150 ℃. The protection level of couplings is usually IP54, which can prevent dust and splash water. Products with special sealing designs can reach IP65. In terms of chemical resistance, polyurethane elastomers have good resistance to most mineral oils, fats, and solvents, but long-term exposure to strong acids, bases, or polar solvents is not recommended. The anti UV performance cannot be ignored, and outdoor couplings should choose elastic materials with added anti UV agents, otherwise surface cracking may occur.

In terms of electrical performance, the elastic claw coupling performs excellently. The volume resistivity of polyurethane elastomers is usually between 10 ¹² and 10 ¹⁴Ω· cm, and the insulation strength exceeds 20kV/mm, which can effectively block shaft current and protect bearings from electrical corrosion damage. This feature makes it particularly important in variable frequency drive systems to prevent bearing pitting failure caused by high-frequency shaft currents. At the same time, the problem of static electricity accumulation in couplings cannot be ignored. Anti static couplings add conductive fillers (such as carbon black) to the elastic body to reduce the surface resistance to below 10 ⁶ Ω, avoiding the danger of static sparks.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/elastic-claw-couplings.html