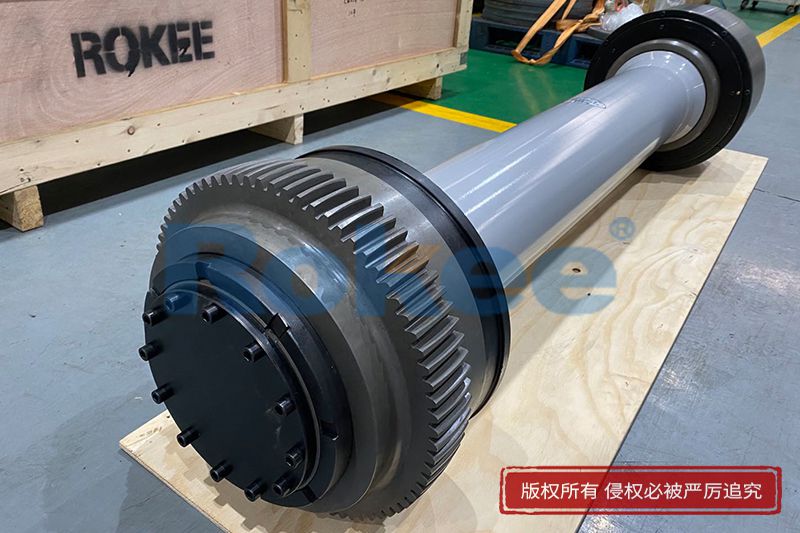

Rokee® Customized WGT Crown Gear Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

The WGT type intermediate sleeve drum shaped gear coupling is a flexible coupling without elastic elements, which belongs to an important branch of mechanical transmission components. This product is designed with an innovative intermediate sleeve combined with drum shaped teeth, specifically for transmission scenarios that require compensation for relative displacement between two axes. It occupies an irreplaceable position in heavy machinery transmission systems. Compared with ordinary couplings, WGT type couplings significantly reduce the risk of component wear and improve the adaptability and reliability of equipment under complex working conditions through their unique structure.

From the perspective of structural composition, the WGT drum shaped gear coupling consists of core components such as an internal gear ring with the same number of teeth and a flange half coupling with external teeth. Its most prominent feature is the adoption of a drum shaped tooth design, which means that the outer teeth are made into a spherical shape, with the center of the spherical surface located on the gear axis. This design allows for a larger backlash between the teeth compared to regular gears, allowing for greater angular displacement (with a 50% increase in compensation capability compared to spur couplings), while improving the contact conditions of the teeth, significantly enhancing the ability to transmit torque, and extending service life. When there is angular displacement, the drum shaped teeth can ensure an ideal contact state along the tooth width direction, avoiding the edge compression problem of traditional straight tooth couplings.

The intermediate sleeve design is another major feature of the WGT type, which adapts to the transmission requirements of larger shaft spacing by increasing the connection length, while maintaining excellent displacement compensation capability. The intermediate sleeve is usually made of high-strength alloy steel and undergoes precision machining to ensure high-precision fit with the two end couplings. The intermediate sleeve of modern WGT couplings also integrates lubrication channels and sealing structures, which facilitate maintenance and prevent contaminants from entering the meshing area. This design is particularly suitable for long wheelbase transmission systems, such as steel rolling equipment, mining hoisting machinery, and other large installations.

From the perspective of material technology, modern WGT drum shaped gear couplings are made of high-quality alloy steel (such as 42CrMo, 20CrMnTi, etc.) and undergo carburizing quenching or nitriding treatment to achieve a tooth surface hardness of HRC50-60 while maintaining the toughness of the core. The application of five axis linkage CNC gear grinding technology ensures that the tooth profile accuracy is controlled within ± 0.005mm, and the transmission efficiency is as high as 99.7%. Hot assembly technology further improves the coaxiality and load-bearing capacity of components, enabling products to meet the most demanding industrial application requirements.

The WGT drum shaped gear coupling exhibits various performance advantages, making it stand out among many types of couplings. Compared with traditional spur gear couplings, the WGT type has an average load capacity increase of 15-20% under the same outer diameter of the inner gear sleeve and maximum outer diameter of the coupling, which directly translates into a more compact design or higher safety margin. The angular displacement compensation is significantly increased, and when the radial displacement is zero, the allowable angular displacement can reach 1 ° 30 ', which is 50% higher than the 1 ° of the straight tooth type. This enhanced compensation capability enables it to better adapt to installation errors and shaft deformation during operation.

From the perspective of transmission quality, WGT type couplings have excellent operational stability. The drum shaped tooth surface fundamentally improves the contact conditions between the inner and outer teeth, eliminating the problems of edge compression and stress concentration at the straight tooth end under angular displacement conditions. The optimized tooth friction characteristics not only reduce operating noise (usually controllable below 75dB), but also extend maintenance cycles by 30-50%. Practical applications have shown that under good lubrication and normal alignment conditions, the service life of WGT couplings generally exceeds 5 years, significantly reducing equipment maintenance costs and downtime.

The technical parameters of WGT drum shaped gear coupling cover a wide range of industrial needs. According to JB/T7004-93 standard, its nominal torque range is from 710N · m to 3150kN · m, suitable for shaft diameters of 12-400mm, and the maximum allowable speed is 7500r/min (depending on the specific model). The model series is complete, including multiple specifications such as WGT1 to WGT24. Users can choose the appropriate model based on key parameters such as torque, speed, and shaft diameter. Taking the common WGT6 type as an example, it is suitable for a shaft diameter of 50mm, a shaft hole length of 112mm, and a weight of about 15kg, which can meet the needs of most medium-sized transmission systems.

Displacement compensation capability is the core performance indicator of WGT type. In addition to excellent angular compensation capability, it can also compensate for both axial and radial displacement simultaneously. Typical parameters are: axial displacement ± 5-15mm (larger with intermediate sleeve design), radial displacement 0.4-6.3mm (increasing with specifications). This multi-directional comprehensive compensation characteristic enables it to effectively absorb installation errors and shaft deformation during operation, protecting related components such as bearings and seals. It is worth mentioning that the WGT type outer gear sleeve has a trumpet shaped tooth end, which makes the installation and disassembly of the inner and outer teeth very convenient and greatly reduces maintenance time.

From the perspective of structural strength analysis, the WGT drum shaped gear coupling adopts finite element optimization design to reduce weight while ensuring the strength of key parts. The latest lightweight design, through topology optimization, has successfully reduced weight by 12-15% under the same load-bearing capacity, lowering the inertial load on rotating components. The bearing part adopts four column cylindrical roller bearings or special composite material bushings, with a service life of over 15000 hours.

WGT drum shaped gear couplings have been widely used in various industrial fields due to their excellent low-speed and heavy-duty performance. The metallurgical industry is one of its most important application scenarios. In equipment such as hot rolling mills, cold rolling mills, and straightening machines, WGT type couplings play a key role in connecting electric motors and rolling mills, and can withstand huge impact loads and thermal deformations.

The mining and lifting transportation field is another important application market. The lifting and traveling mechanisms of mine hoists, port gantry cranes, and bridge cranes often use WGT type couplings, which have excellent impact resistance and can adapt to harsh working conditions such as frequent start stop and load changes.

In the fields of energy and chemical engineering, WGT drum toothed couplings also perform excellently. Large compressors, pump sets, fans and other equipment use them to compensate for shaft displacement caused by pipeline stress.

With technological advancements, WGT drum shaped gear couplings have also entered emerging fields. The connection between the wind turbine gearbox and the generator is gradually adopting an improved drum shaped gear coupling, which has excellent compensation capability to adapt to the shaft displacement caused by tower shaking. The transmission system of high-speed railways has also begun to use lightweight designed WGT couplings to adapt to dynamic conditions at a speed of 350 kilometers per hour. These new applications are constantly driving innovation and development in product technology.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/wgt-crown-gear-coupling.html