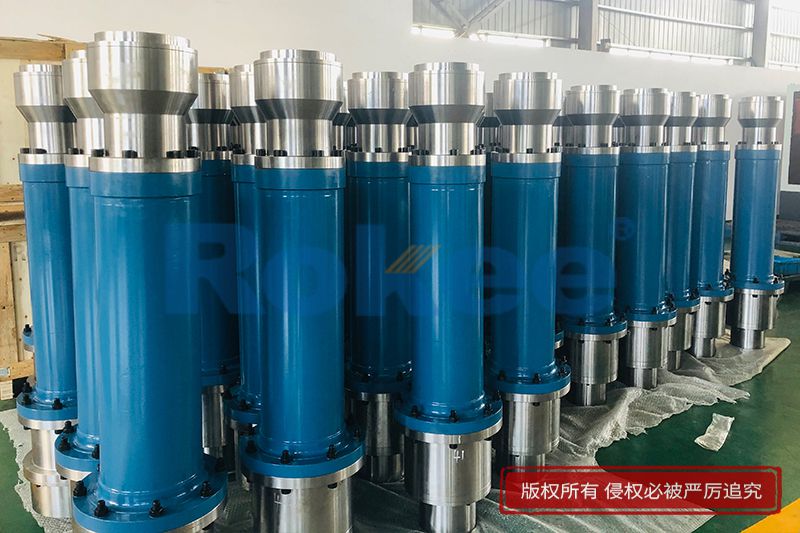

Rokee® Customized Safety Spring Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

The safety spring coupling is a high-performance mechanical transmission device widely used in various situations where torque transmission is required while bearing radial, angular, and axial deviations.

The spring safety coupling mainly consists of two half couplings, two half covers, two sealing rings, and spring plates. The core component is the spring plate, which is embedded in the tooth slots of the two half couplings. Through the deformation of the spring plate, torque is transmitted and the connection between the driving shaft and the driven shaft is achieved.

The working principle of a spring safety coupling is based on the elastic deformation of the spring plate. When the driving shaft rotates, its teeth generate axial force on the spring plate, driving the driven shaft to rotate. Due to the point contact between the spring plate and the tooth arc surface, the coupling can obtain greater flexibility and adapt to various deviations. During the process of transmitting torque, the elastic deformation of the spring plate can also have a damping effect.

Performance characteristics

Greater flexibility: Due to the point contact design between the spring plate and the tooth arc surface, the spring safety coupling can adapt to larger radial, angular, and axial deviations.

Good vibration reduction effect: The elastic deformation of the spring plate can absorb and reduce the vibration of the mechanical system, improving the stability and service life of the equipment.

Strong load-bearing capacity: Spring safety couplings can withstand large torque transmission and are suitable for various heavy-duty applications.

Safe and reliable: The coupling has overload protection function. When the transmitted torque exceeds the set value, the spring plate will undergo plastic deformation or fracture, thereby protecting the mechanical system from damage.

When installing a spring safety coupling, it is necessary to ensure that the gap and angular deviation between the two couplings are within the specified range. Usually, the clearance and radial deviation are measured every 90 degrees to ensure that they do not exceed the specified values. At the same time, attention should be paid to the selection of impact points and the control of impact force to avoid problems such as misalignment of the coupling axis or inability of the coupling to enter. Spring safety couplings require regular lubrication to maintain good working condition. It is usually recommended to use lithium based grease that can resist centrifugal force, has separation stability, is free of impurities, and does not corrode carbon steel and nitrile rubber. It is recommended to check the lubrication condition once a year and inject grease with a grease gun until excess grease overflows from the hole.

Spring safety couplings are widely used in diesel power devices such as ships, diesel locomotives, diesel generator sets, and heavy vehicles. In addition, it is also applicable to various mechanical equipment that requires torque transmission and can withstand multiple deviations at the same time, such as paper making machinery, textile machinery, chemical machinery, etc.

The safety spring coupling, especially the spring safety coupling, has the characteristics of high flexibility, good vibration reduction effect, strong load-bearing capacity, and safety and reliability. During installation and maintenance, certain methods and precautions need to be followed to ensure its normal operation. Spring safety couplings have demonstrated their unique advantages and wide application value in various situations that require torque transmission and withstand multiple deviations.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/safety-spring-coupling.html