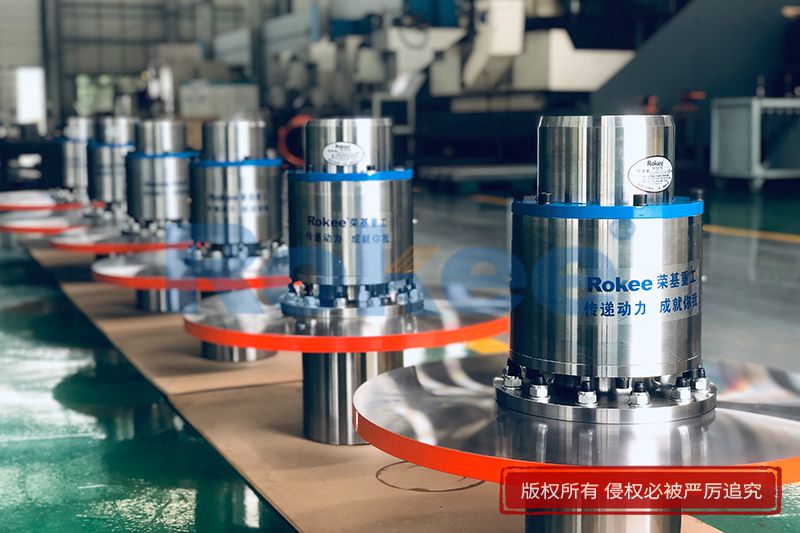

Rokee® Customized WGP Crown Gear Coupling With Brake Disc for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

WGP crown toothed coupling with brake disc is a high-performance mechanical transmission component that integrates transmission and braking functions, widely used in heavy equipment in metallurgy, mining, lifting and transportation industries. The WGP drum toothed coupling with brake disc is an important derivative model of the WG drum toothed coupling series, belonging to a type of rigid flexible coupling. It consists of core components such as an inner ring gear with the same number of teeth and a flange half coupling with outer teeth, and innovatively integrates a brake disc structure, making it have dual functions of power transmission and fast braking.

Compared with traditional spur gear couplings, the most significant feature of WGP type is the use of drum shaped teeth design. This design makes the external teeth into a spherical shape, with the center of the sphere located on the gear axis, and has a larger tooth flank clearance than ordinary gears. The innovative structure of the drum shaped teeth brings three major advantages: firstly, it allows for greater angular displacement compensation (up to 1 ° 30 ', which is 50% higher than the straight tooth type); The second is to improve the contact conditions of the tooth surface and avoid stress concentration caused by the edge compression of straight teeth; Thirdly, it significantly improves the ability to transmit torque, with an average increase of 15-20% in load-bearing capacity under the same size. These characteristics make it particularly suitable for heavy-duty situations where there are installation errors or axis offsets during operation.

The brake disc components of couplings are usually made of high-strength cast iron or alloy steel, with diameters ranging from 315mm to 1000mm. Different friction coefficients of brake pads can be selected according to different braking needs. The integrated design of the brake disc and gear coupling saves installation space and simplifies the structural layout of the transmission system, making it particularly suitable for situations where rapid braking is required, such as the lifting mechanism of lifting equipment and the transmission system of metallurgical rolling mills.

The WGP crown gear coupling with brake disc has a wide range of parameters to adapt to different working conditions. Its nominal torque covers 710N · m to 160000 N · m, which can meet the transmission requirements of light to heavy machinery. In high-speed application scenarios, couplings that have undergone precision dynamic balancing processing are allowed to operate at speeds up to 4000r/min or even higher (such as some models in the WG type foundation series that can reach 7500r/min), ensuring stability during high-speed operation.

The shaft hole configuration of the coupling is extremely flexible, with standard shaft hole diameters starting from 12mm and increasing in a gradient of 2-5mm, up to a maximum of 400mm (different models may vary). The types of shaft holes include Y-shaped (cylindrical hole), J1 type (short cylindrical hole with countersunk hole), and Z1 type (long cylindrical hole with countersunk hole), with lengths ranging from 32mm to 112mm depending on the diameter. This diversified shaft hole design enables it to adapt to the connection needs of the vast majority of transmission shafts, and users can choose the most suitable interface form according to the actual situation of the equipment.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/wgp-crown-gear-coupling-with-brake-disc.html