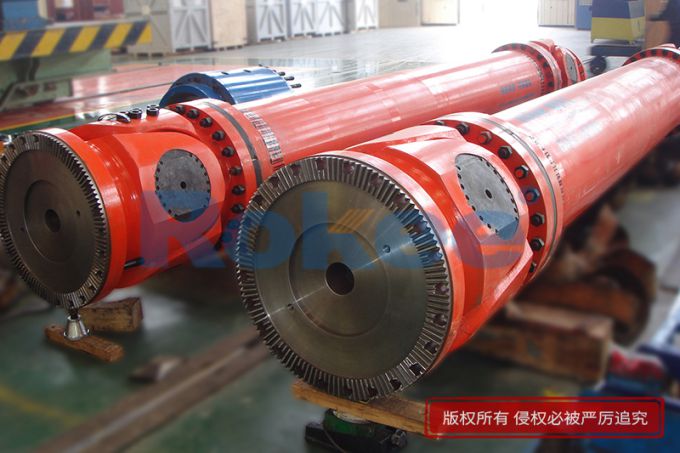

Rokee® Customized ROWH Heavy-duty Metallurgical Universal Joint Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

The heavy-duty metallurgical universal joint coupling is a high torque flexible coupling device with a cross shaft as the core transmission component, designed specifically for extreme working conditions in the metallurgical industry.

Structure

Cross shaft assembly: forged from 42CrMo alloy steel, surface treated with high-frequency quenching (hardness HRC58-62), with a fatigue life of over 100000 hours;

Fork head component: integral forging fork head (SWC-BH type) or split flange structure (SWP type), with an increase in impact resistance of 30% -50%;

Bearing system: cylindrical roller bearings or tapered roller bearings are configured, and lubrication methods are divided into grease lubrication (-30 ℃~150 ℃) and centralized oil lubrication (applicable to high-temperature rolling mills).

Compensation capability

Angular compensation: 15 °~25 ° (recommended ≤ 10 ° for heavy-duty metallurgical conditions to extend service life)

Radial offset: ± 5mm (dynamic condition)

Axial expansion and contraction: ± 20mm (with flower key expansion sleeve design)

Special performance requirements for metallurgical industry

Extreme load capacity

Nominal torque range: 1.25~1000 kN · m

Instantaneous overload capacity: up to 3 times the rated torque (to cope with impact loads such as steel jamming on the rolling mill)High temperature resistant design

Material temperature resistance: -40 ℃~280 ℃

Bearing lubrication: High temperature lithium grease or forced oil circulation systemAnti pollution and maintenance free

Sealing System: Triple Maze Seal+Fluororubber Lip Seal (Anti oxidation Iron Scale Invasion)

Maintenance cycle: 5000 hours under normal working conditions, reduced to 2000 hours for heavy-duty continuous production

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/rowh-heavy-duty-metallurgical-universal-joint-coupling.html