Rokee® Customized Diaphragm Couplings For Motor Units for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

As a key component in modern mechanical transmission systems, diaphragm couplings play an indispensable role in motor devices. This high-performance metal elastic element flexible coupling is widely used in various industrial fields due to its unique structure and excellent performance.

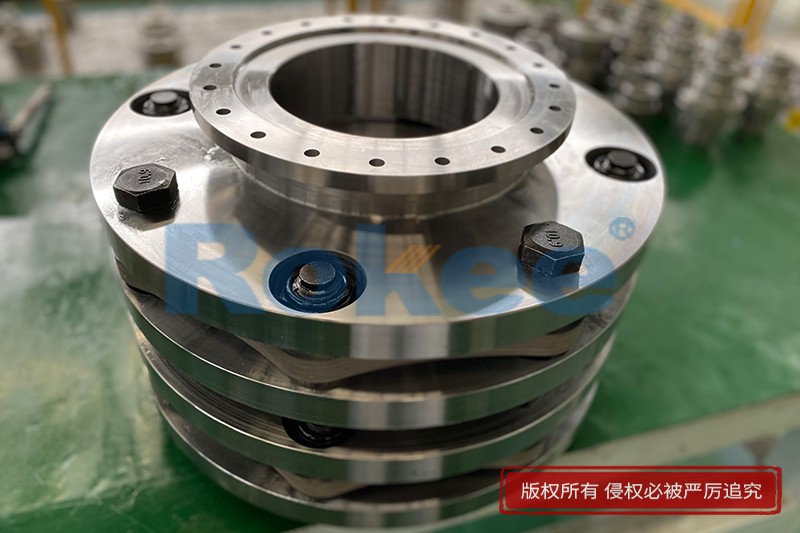

Diaphragm coupling is a high-performance coupling device that utilizes the elastic deformation of metal diaphragms to compensate for the relative displacement between the two connected shafts. It is composed of several sets of stainless steel thin plates connected to the two halves of the coupling through bolts in a staggered manner. Each set of membranes is composed of several stacked pieces, forming a unique flexible connection structure. This design enables the diaphragm coupling to achieve power transmission without lubrication, while effectively addressing various shaft deviation issues.

The core working principle of diaphragm couplings is based on the mechanism of metal elastic deformation. When there is axial, radial, or angular deviation between the motor (driving shaft) and the driven equipment (driven shaft), the diaphragm group absorbs these deviations through its own elastic deformation, thereby ensuring the continuity and stability of power transmission. Unlike traditional gear couplings, diaphragm couplings achieve deviation compensation through overall metal deformation rather than relative sliding between components, which gives them significant advantages of no wear and maintenance.

Structurally, the diaphragm coupling consists of at least one diaphragm and two shaft sleeves. The membrane is fastened to the shaft sleeve with high-precision pins, which ensures torque transmission without reverse clearance. According to application requirements, manufacturers may provide products with different configurations: some use a single membrane design, suitable for situations with small deviations; Some use double or even triple membrane structures, with rigid components added in the middle, significantly improving the ability to compensate for deviations. It is worth mentioning that the double diaphragm coupling can simultaneously undergo bending deformation in different directions, thereby more effectively compensating for complex eccentricity situations.

The performance characteristics of diaphragm couplings are outstanding: compact structure, high strength, long service life, no rotational clearance, and not affected by temperature and oil pollution. These characteristics make it particularly suitable for harsh working conditions such as high temperature, high speed, and the presence of corrosive media. According to industry test data, the transmission efficiency of high-quality diaphragm couplings can reach up to 99.86%, far higher than many traditional coupling types, making it an ideal choice for medium to high speed and high-power transmission.

Diaphragm couplings can be classified into various types based on their structural form and application requirements, each with its unique performance characteristics and applicable scenarios. Understanding these classifications and their structural features is crucial for proper selection and optimization of applications.

The single diaphragm coupling is the most basic form, consisting of a diaphragm group and two shaft sleeves. This structure is relatively simple, with low manufacturing costs, and is suitable for situations where torque transmission requirements are not high and shaft deviation is small. The diaphragm of a single diaphragm coupling is usually designed as a circle or triangle, with a thin thickness that can provide limited elastic deformation in the axial, radial, and angular directions. However, due to the complex multi-directional bending required for the membrane, its adaptability to eccentricity is relatively limited, and it is generally suitable for working conditions where the deviation angle does not exceed 1.5 degrees. Single diaphragm couplings are widely popular in servo systems and small mechanical devices due to their compact structure and low moment of inertia.

In contrast, the double diaphragm coupling consists of two sets of diaphragms and an intermediate body, forming a more complex flexible system. This structure enables the coupling to undergo bending deformation in different directions simultaneously, greatly improving its ability to compensate for shaft system deviations. Double diaphragm couplings are particularly suitable for applications with composite deviations (i.e. simultaneous radial, axial, and angular deviations), such as long wheelbase transmissions, operating conditions with significant thermal expansion, or equipment where foundation settlement may occur. Double diaphragm couplings have become a standard configuration in large-scale equipment in industries such as petrochemicals and power.

From the shape of the membrane, there are two common types: linkage type and integral type. The linkage type diaphragm is composed of multiple separated metal strips arranged radially, similar to the spokes of a bicycle wheel, which provides good flexibility and high elasticity; The whole piece membrane adopts a complete metal disk and achieves elastic deformation through a special geometric shape (such as a 6-angle, 8-angle, or 10 angle star shape) opening design. The integral membrane has higher torque rigidity and more precise transmission performance, making it particularly suitable for applications that require high-precision positioning, such as CNC machine tools and robot joints.

Another important classification is the waist tied membrane coupling, whose membrane adopts a special waist tied shape design, making stress distribution more uniform and significantly improving fatigue life. The waist cinching design can effectively reduce centrifugal stress during high-speed rotation, making it perform excellently in high-speed power transmission systems such as aviation and naval vessels. The diaphragm of this type of coupling is usually designed with multiple layers stacked together, and assembled with carefully calculated pre tightening force to ensure stable performance even during high torque transmission.

In addition, depending on the connection method, diaphragm couplings can also be divided into keyway type, expansion sleeve type, and clamping type. The keyway type uses key connections to fix the shaft and coupling, which is the most traditional connection method; The expansion sleeve type uses the tightening force of high-strength bolts to shrink the inner hole of the coupling, achieving an interference fit with the shaft and avoiding the weakening of the shaft strength by the keyway; The clamping type is fastened by split sleeves and bolts, which is easy to install and can achieve seamless transmission. It is particularly suitable for situations that require frequent disassembly and maintenance.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/diaphragm-couplings-for-motor-units.html