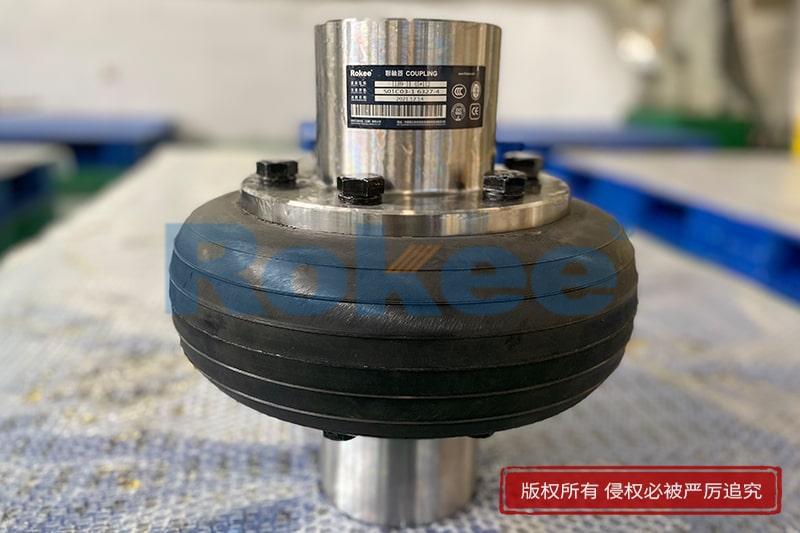

Rokee® Customized LLB Rubber Tyre Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

LLB rubber tyre coupling as a highly elastic coupling device, plays a key role in metallurgical equipment, heavy machinery and other fields. This type of coupling achieves power transmission and deviation compensation through a specially designed rubber tire body, combining excellent shock absorption and buffering performance with durability and reliability.

LLB rubber tire coupling is an elastic coupling device designed specifically for heavy-duty impact conditions and is an important member of the tire type coupling family. Its core feature is the use of an integral rubber tire body as an elastic element, which effectively absorbs vibration and impact energy while transmitting torque, and can compensate for various deviations between shaft systems. Compared with ordinary couplings, LLB type is particularly suitable for harsh working environments such as humidity, dust, frequent start stop, and variable forward and reverse rotation.

This type of coupling adopts an axial assembly structure, consisting of two flange plates with shaft holes and a rubber tire body in the middle to form an integral structure. This design eliminates the need to move the axial position of the coupling when replacing the tire body, greatly simplifying the maintenance process. The interior of rubber tires is usually reinforced with nylon thread or nylon cloth, which not only maintains the elastic properties of rubber, but also significantly improves the overall strength and durability.

The main difference between LLB type and similar products (such as UL type and LLA type) is that:

Tire body thickness: LLB type tires have a thicker body and stronger load-bearing capacity than UL type tires

Structural form: Adopting a non open integral tire body design for better sealing performance

Application focus: Optimization design specifically for high load conditions of metallurgical equipment

The mechanical structure of LLB rubber tyre coupling has been carefully designed to ensure reliable operation under various working conditions:

Core component composition

Flange components:

Material: High quality carbon steel or alloy steel

Processing accuracy: H7 level shaft hole, end face Ra1.6 μ m

Connection method: keyway connection or cone sleeve clampingRubber tire body:

Structure: Overall circular, reinforced with multiple layers of nylon cord inside

Rubber formula: Oil resistant, anti-aging special synthetic rubber

Process: Compression molding, vulcanization molding, seamlessTightening system:

High strength alloy steel bolt assembly

Anti loosening washer or thread locking adhesive

Uniform pre tension design

LLB couplings achieve multiple functions through the elastic deformation of rubber bodies:

Torque transmission: active flange → bolt assembly → tire body → bolt assembly → driven flange

Vibration absorption: Viscoelastic dissipation of vibration energy in rubber molecular chains

Deviation compensation:

Axial displacement: tensile/compressive deformation of tire body

Radial displacement: fan-shaped bending of tire body

Angular deviation: Cone distortion of tire body

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/llb-rubber-tyre-coupling.html