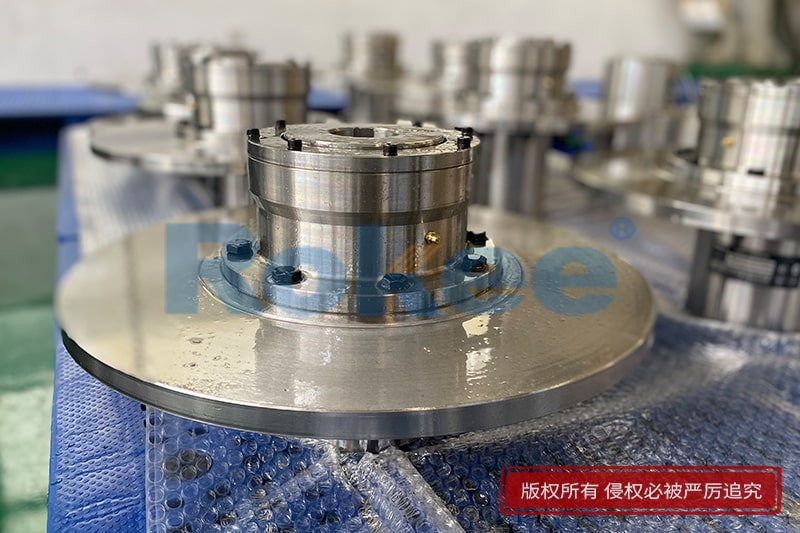

Rokee® Customized Toothed Coupling With Brake Disc for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

The toothed coupling with brake disc is a key component in industrial transmission systems, which integrates transmission and braking functions and is widely used in mechanical equipment that requires precise braking and safety control. This type of coupling achieves dual functions of efficient power transmission and rapid braking through precise tooth design and reliable braking structure.

Gear coupling with brake disc is an integrated transmission and braking device that combines traditional gear coupling with brake disc to form a compact and fully functional power transmission unit. This design not only saves installation space, but also improves the response speed and braking reliability of the transmission system, especially suitable for situations such as lifting machinery, metallurgical equipment, mining machinery that require frequent start stop and emergency braking.

Structural integration is a prominent feature of this type of coupling. Compared with ordinary gear couplings, the brake disc model integrates the brake disc directly onto the coupling body, usually located on one end flange of the coupling. This design eliminates the problems of large axial space occupation and difficult centering that exist in traditional split brake systems. Taking the WGZ type drum shaped toothed coupling with brake wheels as an example, its overall length is shortened by more than 30% compared to the "coupling+separate brake disc" combination of the same specifications, greatly simplifying the layout of the transmission chain.

Dual functional collaboration is another key feature. The toothed coupling with brake disc is equipped with:

Power transmission function: By using a precision meshing tooth structure to transmit torque, the transmission efficiency can reach up to 99.7%

Quick braking function: The integrated brake disc can withstand braking torque up to 4 times the rated torque

Safety protection function: Some models are equipped with overload shear pins, which cut off power transmission when overloaded

The application of drum tooth technology endows this type of coupling with excellent deviation compensation capability. The drum shaped outer teeth design on the brake disc side allows for:

Axial displacement compensation: ± 5-15mm (suitable for shaft thermal expansion)

Radial displacement compensation: 3-12mm (absorbing installation errors)

Angular displacement compensation: 1.5 ° -2.5 ° (compensating for frame deformation)

This compensation capability ensures that even in the presence of shaft misalignment, the coupling can maintain good engagement without affecting the reliability of the braking function. Actual application data shows that the brake disc coupling with drum shaped teeth design reduces the tooth surface contact stress by 35% compared to the straight tooth type, and extends the service life by 2-3 times.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/toothed-coupling-with-brake-disc.html