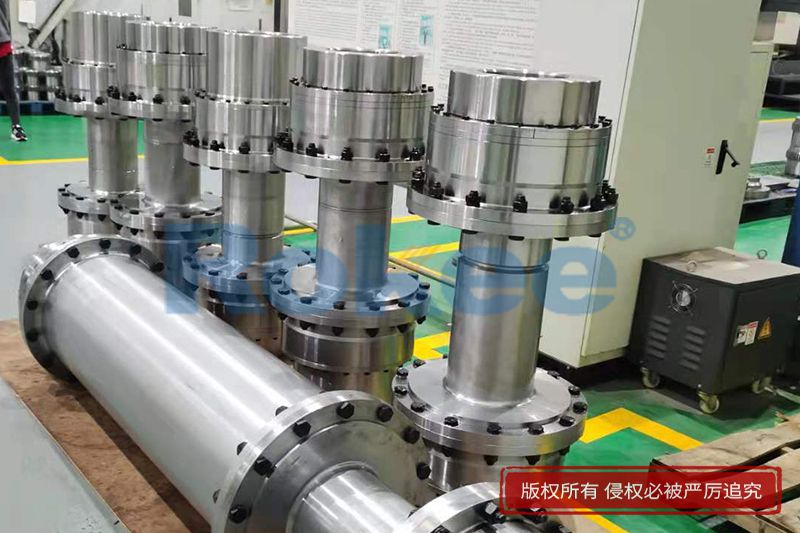

Rokee® Customized Tooth Coupling With Intermediate Shaft for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

Tooth couplings with intermediate shafts are key components in mechanical transmission systems, particularly suitable for working conditions that require compensation for large shaft spacing and relative displacement. The tooth coupling with an intermediate shaft is a specially designed flexible coupling that significantly expands the application range of traditional tooth couplings by adding an intermediate connecting sleeve between the two half couplings. This type of coupling mainly consists of three parts: two shaft sleeve half couplings with external teeth, an intermediate sleeve with internal teeth, and necessary connecting fasteners. The length of the intermediate sleeve can be customized according to the actual shaft spacing requirements, usually with a 10-15% expansion allowance to accommodate axial displacement during installation and operation.

From the perspective of working principle, this type of coupling transmits torque through gear meshing, while compensating for axial, radial, and angular deviations using tooth flank clearance and special tooth profile design. When the driving shaft rotates, power is transmitted to the driven shaft through the meshing of the outer gear sleeve and the inner teeth of the intermediate sleeve. The presence of the intermediate sleeve allows the coupling to adapt to longer shaft spacing. The drum shaped tooth design further enhances the compensation capability, allowing the coupling to maintain smooth transmission even in the presence of installation errors or shaft deformation during operation.

The sealing and lubrication system is a key design element of this type of coupling. The intermediate sleeve is usually designed with an integrated lubrication channel and a dual sealing structure to prevent lubricant leakage and contamination from entering the mating area. The high-performance model adopts a labyrinth seal combined with high-quality lip seals to ensure long-term maintenance of good lubrication even in harsh environments. The lubrication method can choose between grease lubrication or forced oil circulation lubrication. The latter is recommended for heavy-duty conditions to better cool the tooth surface and extend its service life.

The tooth coupling with intermediate shaft has formed a complete series of products, commonly including WGT type, GIICLZ type, CLZ type, etc. The WGT type follows the JB/T7004-93 standard, with a nominal torque range from 710N · m to 3150kN · m, suitable for shaft diameters of 12-400mm, and a maximum allowable speed of 7500r/min (depending on the specific model). The length of the intermediate sleeve can be customized according to requirements, with standard specifications ranging from 100mm to 2000mm, and can be longer under special working conditions.

The performance comparison between drum tooth and straight tooth designs is significant. Drum shaped tooth couplings (such as WGT type) allow for greater comprehensive displacement compensation: radial displacement of 0.4-6.3mm, axial displacement of ± 5-15mm, and angular displacement of 1 ° 30 ', with a 50% improvement in compensation capability compared to straight tooth couplings. Under the same size, the load-bearing capacity of the drum tooth design is increased by an average of 15-20%, and the transmission efficiency is as high as 99.7%. Modern drum shaped tooth couplings adopt finite element optimization design, which ensures the strength of key parts while reducing weight. Some models have successfully reduced weight by 12-15% through topology optimization.

High end standards are reflected in materials and manufacturing processes. External gear shaft sleeves are usually made of 42CrMo alloy steel that has undergone carburizing and quenching treatment, with a surface hardness of HRC50-60; The internal gear ring is made of 20CrMnTi material and its wear resistance is enhanced through nitriding process. The key tooth surface is processed using five axis linkage CNC gear grinding technology, with an accuracy controlled within ± 0.005mm. The application of hot assembly technology further improves the coaxiality of components, enabling products to meet demanding industrial application requirements.

The displacement compensation capability is the core indicator of this type of coupling. In addition to excellent angular compensation capability, it can also compensate for both axial and radial displacement simultaneously. The intermediate sleeve design enables the coupling to adapt to larger changes in shaft spacing, especially suitable for situations where the wheelbase changes due to thermal expansion or foundation settlement. Some high-end models are also equipped with a "dual redundant bearing system", which can maintain short-term operation even when one set of bearings fails, providing a time window for planned maintenance.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/tooth-coupling-with-intermediate-shaft.html