Rokee® Customized Tooth Coupling With Brake Disc for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

The toothed coupling with brake disc is a special type of coupling that combines the transmission characteristics of a toothed coupling with the safety braking function of a brake disc.

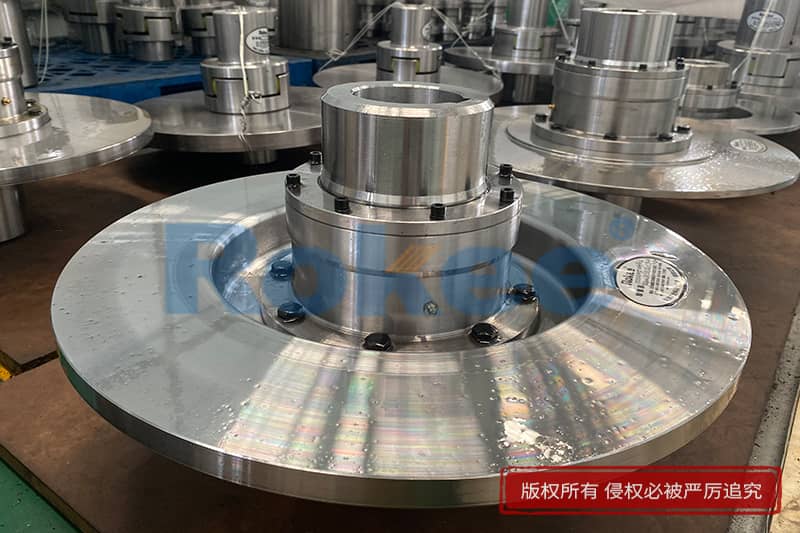

Gear couplings with brake discs are usually composed of internal gear rings with the same number of teeth and flange half couplings with external teeth. Among them, the external teeth are divided into two types: straight teeth and drum teeth. Drum shaped teeth are made by shaping the outer teeth into a spherical surface, with the center of the spherical surface on the gear axis. This design results in a larger backlash between the teeth compared to regular gears, allowing for greater angular displacement in drum shaped gear couplings (compared to spur gear couplings). This characteristic can improve the contact conditions of teeth, enhance the ability to transmit torque, and extend the service life.

In addition, the toothed coupling with brake disc also includes a brake disc that is clamped and fixed between the connecting flange and the connecting sleeve. The brake disc is rigidly connected to the right shaft sleeve, and the braking load and vibration during the braking process are borne by the right shaft sleeve, so it will not cause damage to the meshing performance of the drum teeth.

Gear couplings with brake discs are mainly used to connect the power input shaft and power output shaft, and to achieve power transmission. Meanwhile, equipped with brake discs, it can also provide safe braking function when needed. This type of coupling is suitable for connecting horizontal two coaxial transmission shaft systems and is widely used in heavy machinery equipment such as metallurgy, lifting, water conservancy, and mining.

The performance parameters of a toothed coupling with a brake disc include nominal torque, allowable speed, shaft hole diameter, shaft hole length, and brake disc diameter. The specific values of these parameters will vary depending on the model and specifications of the coupling. For example, some models of drum toothed couplings with brake discs may have larger brake disc diameters and transmit nominal torque to meet the high requirements of heavy machinery equipment for braking performance and transmission capacity.

Precautions for use

When installing a toothed coupling with a brake disc, it is necessary to ensure the assembly accuracy and coaxiality requirements of each component to avoid problems such as vibration and noise caused by improper installation.

During use, the wear of the coupling should be regularly checked, and severely worn components should be replaced in a timely manner to ensure the normal operation of the coupling and extend its service life.

When performing braking operations, attention should be paid to the fit between the friction pads of the brake disc and the brake disc, as well as the application method and magnitude of braking force, to avoid equipment damage or safety accidents caused by improper braking.

The toothed coupling with brake disc is a transmission component with a special structure and function, which combines the transmission characteristics of the toothed coupling with the safety braking function of the brake disc, and has a wide range of application prospects in heavy machinery equipment.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/tooth-coupling-with-brake-disc.html