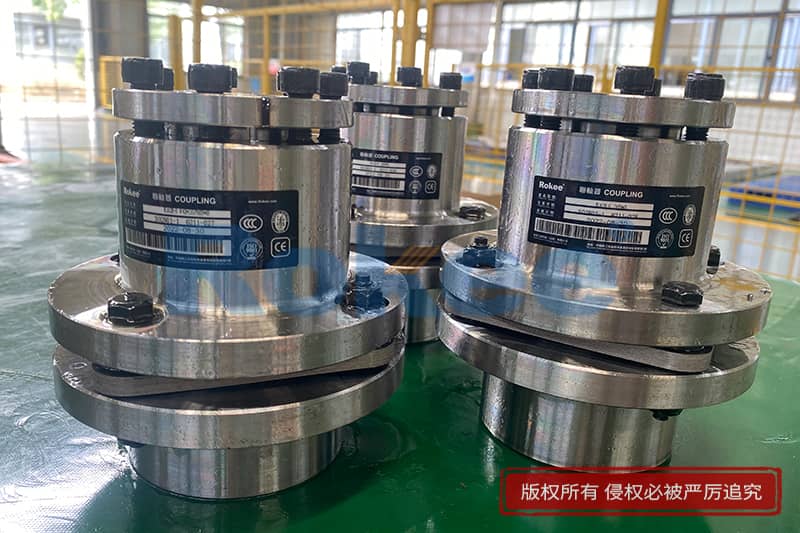

Rokee® Customized Single Diaphragm Coupling With Tensioning Sleeve for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

The single diaphragm coupling with expansion sleeve is a high-performance transmission component that integrates keyless connection technology and elastic compensation function, playing a key role in modern industrial transmission systems.

The single diaphragm coupling with expansion sleeve is composed of three major functional modules to form a precision collaborative system:

Expansion connection module: adopting Z1 or Z3 expansion sleeve structure, including inner and outer cone rings, high-strength tension bolts, and anti loosening components. The shaft hub seamless connection is achieved through the radial expansion force generated by bolts, and the typical bolt pre tightening force can reach 8.8 or 10.9 strength standards.

Diaphragm elastic module: composed of 3-12 stacked 304/316L stainless steel thin sheets with a thickness of 0.2-1.2mm, laser cutting is used to ensure shape and position tolerances. The membrane group undergoes special heat treatment processes (such as solution treatment) to obtain the best elastic properties, and the fatigue life can reach more than 10 ^ 7 cycles.

Structural support module: including half couplings made of 45 # steel or aluminum alloy material (with blackened or anodized surface), SAE grade high-strength connecting bolts (usually 12.9 grade), and corrosion-resistant limit washers. Precision machining ensures that the end face runout is ≤ 0.02mm, and the dynamic balance level can reach G2.5.

The power transmission path of the coupling presents a dual guarantee characteristic: it mainly relies on the static friction force between the expansion sleeve and the shaft to transmit torque (friction coefficient μ is usually 0.12-0.15), and assists in providing overload protection through the rigid connection of the diaphragm group. When the system torque exceeds the design value, the diaphragm undergoes elastic deformation to absorb impact energy, while the expansion sleeve connection surface maintains no relative sliding. This design makes its torque transmission efficiency as high as 99.8%, far exceeding the 97% -98% of gear couplings.

Dynamic compensation principle: When the shaft system experiences misalignment, the single diaphragm structure can effectively compensate for:

Axial deviation: ± 0.5-2mm

Radial deviation: ± 0.2-0.8mm

Angular deviation: ± 0.5 ° -1.5 °

The elastic deformation of the diaphragm can reduce the attached load on the bearing by 60-80%, significantly extending the service life of the equipment.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/single-diaphragm-coupling-with-tensioning-sleeve.html