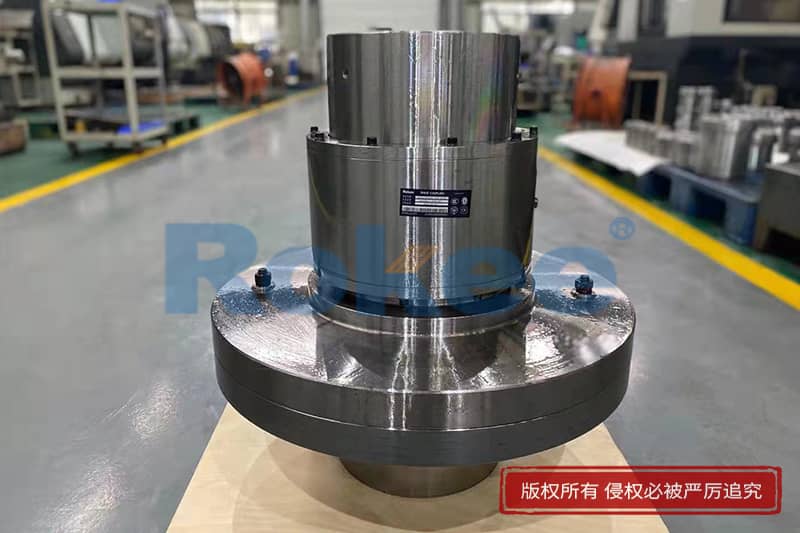

Rokee® Customized Safety Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

As a key protective device in modern mechanical transmission systems, safety couplings play an irreplaceable role in industrial production. It can not only effectively transmit power, but also provide reliable protection in case of system overload or sudden failure, avoiding equipment damage and safety accidents.

A safety coupling is a mechanical transmission component with integrated protection functions, mainly used to connect the active machine and the working machine, providing overload protection while transmitting motion and power. Compared with ordinary couplings, its most significant feature is the ability to automatically cut off or limit power transmission when the system torque exceeds the set value, thereby protecting key equipment such as motors and reducers from damage. After the abnormal working conditions disappear, most safety couplings can automatically or manually restore the connection to ensure production continuity.

From the perspective of working principle, safety couplings mainly achieve protective functions through three mechanisms: frictional slippage, mechanical separation, and magnetic disengagement. Friction type safety couplings use preset frictional force to transmit torque. When the load exceeds the set value, relative sliding occurs between the friction plates; The shear pin method cuts off power transmission by accurately calculating the shear pin to break when overloaded; Magnetic safety couplings rely on the coupling effect of permanent magnets or electromagnets to automatically disengage under abnormal working conditions. These protective mechanisms enable the safety coupling to respond promptly to system abnormalities and minimize the losses caused by faults.

The core value of a safety coupling lies in three aspects: firstly, protecting equipment safety and avoiding mechanical damage caused by overload, stalling, or sudden parking; The second is to reduce maintenance costs, minimize downtime losses and repair costs caused by equipment failures; The third is to improve system reliability by ensuring stable transmission process through precise torque control.

Safety couplings can be classified into various types based on their structural principles and application scenarios, each with its unique advantages.

Friction type safety couplings are the most common type, using friction plates or friction blocks as torque transmission media. Its core feature is adjustable slip torque, which is set by adjusting the spring pressure or the number of friction plates to set the protection value. This type of coupling has a simple structure and is easy to maintain, suitable for small and medium-sized equipment and frequent start stop situations. The internal tension friction type safety coupling uses a cylindrical spiral spring to press the bow shaped friction plate through the middle ring. The frictional force determines the sliding torque, and the protection threshold can be adjusted by replacing the spring.

The shear pin type safety coupling transmits torque through a precisely designed shear pin, and protects against pin breakage when overloaded. This type of coupling protection action is clear and reliable, but it requires replacing the shear pin to restore use, making it suitable for situations with small and infrequent impact loads. Its advantages lie in low cost, simple structure, and wide application in equipment such as pumps and fans.

Steel ball safety coupling is a special design that achieves power transmission and overload protection through the centrifugal force of steel balls. During normal operation, the steel ball tightly adheres to the inner wall of the shell and rotates synchronously; When the load is abnormal, the steel ball and the shell generate sliding friction, cutting off power transmission. This type of coupling is particularly suitable for equipment with load starting such as centrifugal water pumps and blowers, which can provide approximate no-load starting characteristics and reduce motor load.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/safety-coupling.html