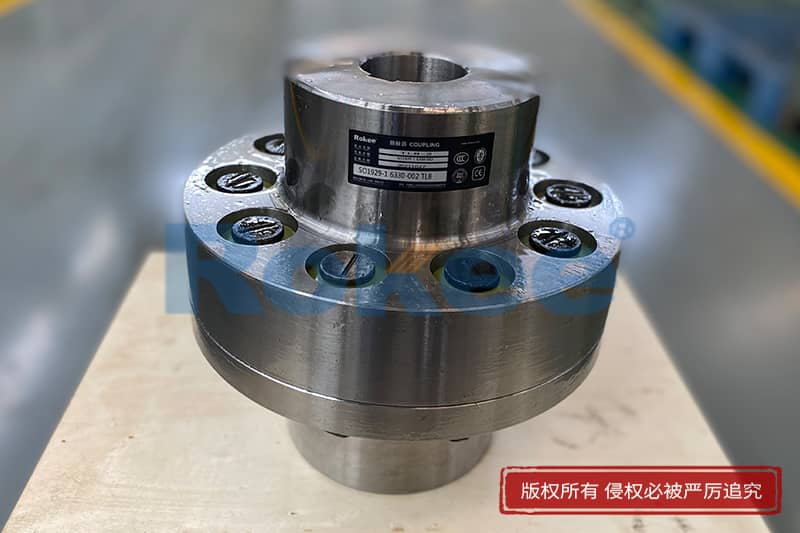

Rokee® Customized LT Pin Bush Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

LT Pin Bush Coupling belongs to non-metallic elastic element flexible coupling, which is structurally similar to flange coupling. However, the connection between the two half couplings does not use bolts, but uses column pins with rubber or leather sleeves to achieve the connection of the two half couplings. This design gives the coupling a certain degree of elasticity and compensation capability.

Main features of LT Pin Bush Coupling

Simple structure: The LT Pin Bush Coupling has a relatively simple structure, is easy to manufacture, and does not require complex processing techniques.

No lubrication required: This coupling does not require lubrication during use, reducing maintenance costs and workload.

Easy to replace: When the elastic sleeve is worn or damaged, it is very convenient to replace without moving the half coupling, thus saving maintenance time and costs.

Compensation performance: The LT Pin Bush Coupling has a certain ability to compensate for the relative offset of the two shafts, and can adapt to certain axial displacement and angular deviation.

Vibration damping and buffering: Due to the use of rubber or leather sleeve pins, this coupling also has certain vibration damping and buffering performance, which can reduce vibration and impact during the transmission process.

LT pin coupling is suitable for transmission systems such as small and medium power water pumps with high speed, good rigidity of the installation base, high centering accuracy, low impact load, and low requirements for vibration reduction. Its high-quality cast iron coupling compensates for shock absorption connection characteristics, making it widely applicable in these fields.

When selecting LT Pin Bush Couplings, it is necessary to determine the appropriate model and specifications based on the specific needs of the transmission system. Meanwhile, due to varying transmission requirements in different application scenarios, this coupling also supports non-standard customization to meet customers' personalized needs.

Precautions

During the installation process, attention should be paid to leaving appropriate distance and clearance to ensure the normal operation and compensation capability of the coupling.

Regularly check the wear of the coupling and replace damaged elastic sleeves and pins in a timely manner to ensure the stability and reliability of the transmission system.

Avoid using couplings under overload or harsh working conditions to prevent equipment damage or safety accidents.

LT pin coupling has a wide range of application value in transmission systems such as small and medium power water pumps due to its simple structure, no need for lubrication, easy replacement, good compensation performance, and vibration damping and buffering advantages.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/lt-pin-bush-coupling.html