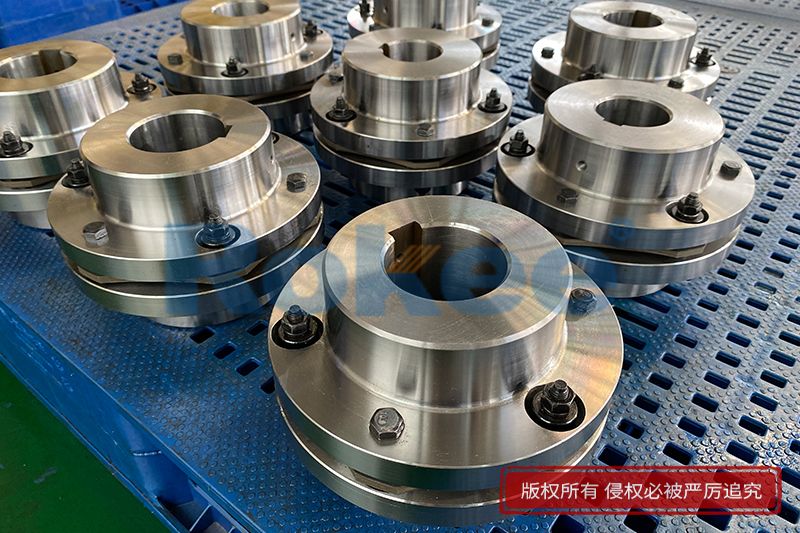

Rokee® Customized JMI Single Membrane Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

JMI single membrane coupling is a high-performance metal elastic element flexible coupling that plays an important role in modern industrial transmission systems. This type of coupling, with its unique structural design and excellent performance characteristics, is widely used in various mechanical equipment that requires torque transmission and compensation for shaft system deviations.

JMI membrane coupling belongs to the basic type of diaphragm coupling with countersunk holes, and its core component is a diaphragm group composed of stainless steel thin plates stacked together. These membranes are connected to the two halves of the coupling by interlocking bolts, forming an elastic connection structure. According to different designs, diaphragms can be divided into two main forms: linkage type and integral type.

Compared with traditional couplings, JMI single diaphragm couplings have the following significant characteristics:

No relative sliding: completely eliminates the common sliding wear problem of gear couplings

No lubrication required: eliminates the hassle of regular refueling and maintenance, reducing usage costs

Compact structure: small size, light weight, saving installation space

High transmission efficiency: up to 99.86%, with extremely low energy loss

Strong corrosion resistance: made of stainless steel material, suitable for harsh working conditions and environments

JMI diaphragm couplings are widely used in many industrial fields due to their excellent performance characteristics

Energy and power industry: high-power generator sets, wind power equipment, pump sets, etc

Petrochemical industry: Compressors, pumps, mixing equipment and other corrosive environments

Metallurgical manufacturing: high torque applications such as rolling mills and continuous casting equipment

Marine aviation: high-speed scenarios such as ship power systems and helicopter transmission systems

General Machinery: Precision Transmission Requirements for Fans, Printing Machinery, Textile Machinery, etc

Compared with toothed couplings, JMI single diaphragm couplings have significant technical advantages:

Maintenance free: No need for regular lubrication, reducing downtime

Long life: No wear parts, the service life can reach 3-5 times that of the gear coupling

Low noise: metal elastic element transmission, running quietly and smoothly

High precision: no backlash, suitable for precision transmission systems

In terms of maintenance, although JMI single diaphragm couplings do not require lubrication, regular inspections are still necessary

Check the tightening status of bolts to prevent looseness

Monitor whether the membrane has cracks or permanent deformation

Observe whether there are any abnormal vibrations or noise during the operation of the equipment

Regularly check the alignment of the shaft, especially after the equipment foundation has settled

JMI steel plate couplings have formed a complete series of products, with main models including:

Basic types: JMI type (with countersunk hole), JMII type (without countersunk hole)

Expansion type: JMIJ type (with intermediate shaft), JMIIJ type (without countersunk hole with intermediate shaft)

When selecting, the following key factors should be considered:

Torque demand: Calculate normal operating torque and peak torque

Speed range: shall not exceed the allowable speed of the coupling

Shaft hole specification: matching equipment shaft diameter and keyway form

Environmental conditions: special requirements for temperature, corrosive media, etc

Deviation compensation: estimating possible axial, radial, and angular deviations

For long wheelbase transmission systems, it is recommended to choose models with intermediate shafts; In confined spaces, the basic model is more suitable. For special working conditions such as high temperature and corrosive environments, customized products made of special stainless steel materials can be selected.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/jmi-single-membrane-coupling.html