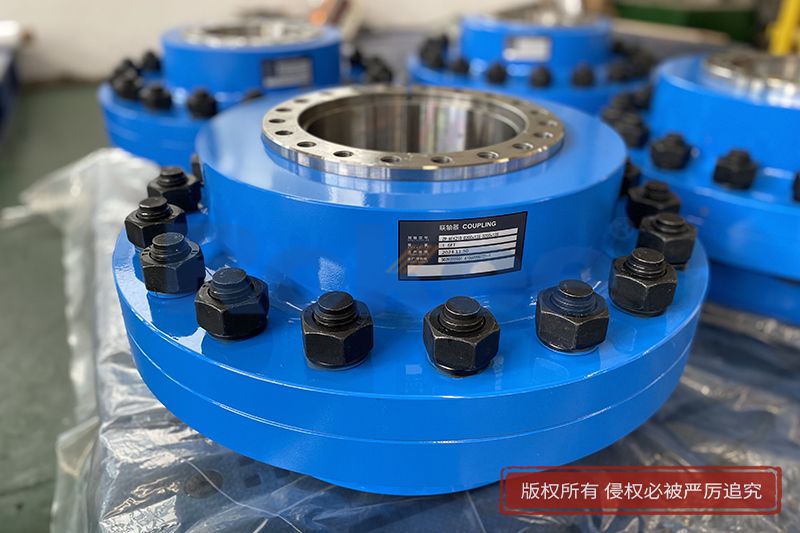

Rokee® Customized Expansion Sleeve Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

Expansion sleeve coupling is a mechanical connecting component that plays an important role in mechanical transmission systems. The expansion sleeve coupling is mainly composed of stainless steel metal diaphragm group (steel sheet), half coupling, locking cover plate, Z1 type expansion sleeve, clamping element, bolt, anti loosening nut, limit washer and other components. These components work together to ensure the stability and reliability of the coupling.

The working principle of the expansion sleeve coupling is that torque is input from the active half coupling, transmitted to the flexible steel plate group through high-strength bolts, and then output through the intermediate sleeve and the driven half coupling. This structural design effectively avoids the sliding loss of traditional couplings and improves transmission efficiency.

Expansion sleeve couplings have various characteristics and advantages, making them the preferred choice for many mechanical transmission systems:

No relative sliding: avoids the wear caused by sliding of traditional couplings, thereby extending their service life.

No lubrication: No need to regularly add lubricating oil, reducing maintenance costs.

No noise: significantly reduces noise during operation, suitable for environments with high requirements for quietness.

Easy disassembly and assembly: With the Z1 type expansion sleeve, keyless connection is achieved, simplifying the installation and disassembly process.

High torque rigidity: capable of withstanding large torques, ensuring the stability and reliability of transmission.

Correction ability: It can compensate for the radial, axial, and angular deviations generated by the two shafts during the transmission process of manufacturing machinery.

Expansion sleeve couplings are widely used in industries such as mining, textiles, packaging, machine tools, papermaking, metallurgy, shipbuilding, agricultural machinery, transportation, chemical industry, and light industry. Especially in transmission systems that require high precision, stability, and reliability, the expansion sleeve coupling plays an irreplaceable role.

In order to ensure the long-term stable operation of the expansion sleeve coupling, regular maintenance and upkeep are required. This mainly includes checking the wear of each component, loosening of fastening bolts, cleaning of dirt, and applying rust proof grease. In addition, during disassembly and installation, it is necessary to strictly follow the operating procedures to avoid damaging the expansion sleeve and other components of the coupling.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/expansion-sleeve-coupling.html