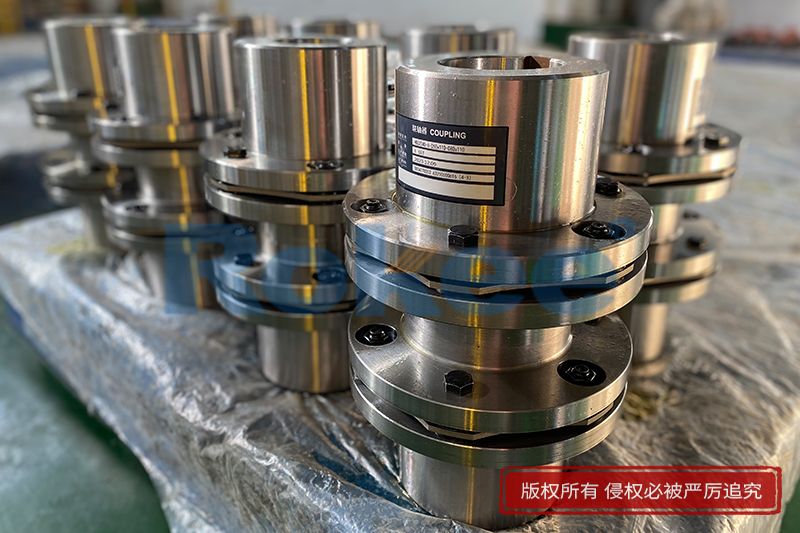

Rokee® Customized Elastic Diaphragm Coupling for Customers, Rokee® is a well-known high-quality supplier of couplings and technical services in China.

Elastic membrane coupling is a high-performance metal elastic element flexible coupling. The elastic membrane coupling is composed of several sets of membranes connected to the two halves of the coupling with bolts in a staggered manner. Each group of membranes is composed of several stacked sheets, and the relative displacement between the two connected axes is compensated for by the elastic deformation of the membranes.

Characteristics and advantages of elastic diaphragm coupling

No lubrication required: The elastic diaphragm coupling does not require lubrication during operation, reducing maintenance costs and work complexity.

Compact structure: Its structural design is compact, small in size, light in weight, and easy to install and carry.

High strength and long service life: Due to the use of high-strength materials such as stainless steel, the elastic diaphragm coupling has high strength and a long service life.

Temperature and corrosion resistance: It can work in environments with high temperatures and corrosive media, and is not affected by temperature and oil stains. Specifically, its working temperature range is usually -20~+250 ℃, with an allowable working temperature of up to 200 degrees.

No rotational clearance: The connection of elastic elements has no clearance, ensuring the stability and accuracy of transmission.

Shock absorption and noise reduction: It has a significant shock absorption effect and operates without noise, improving the operating efficiency and comfort of the equipment.

High transmission efficiency: up to 99.86%, especially suitable for medium and high-speed high-power transmission.

Elastic diaphragm couplings are widely used in industries and fields such as metallurgy, steel rolling, mining, chemical engineering, shipbuilding, pumps, fans, compressors, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, aviation, and high-speed power transmission systems for ships. Especially in situations where high precision, high stability, and long lifespan transmission are required, elastic diaphragm couplings perform exceptionally well.

Installation and maintenance of elastic diaphragm coupling

Preparation before installation: Clean the end faces of both shafts and check the fit of the key slots on the end faces.

After installation inspection: After the installation of the elastic diaphragm coupling, it is necessary to check all screws for normal operation for one shift. If any looseness is found, they must be tightened. Repeat this several times to ensure that it will not loosen.

Lubrication and coating: In order to prevent micro motion wear of the diaphragm during high-speed operation, which may cause micro cracks and damage to the diaphragm bolt holes, solid lubricants such as molybdenum disulfide can be applied between the diaphragms or the diaphragm surface can be treated with anti wear coatings.

Safety inspection: In areas where personal and equipment accidents may occur due to the operation of couplings, appropriate safety measures must be taken.

Exception handling: During operation, the diaphragm coupling should be regularly checked for any abnormal phenomena. If any abnormal phenomena occur, they must be repaired in a timely manner.

In addition, the main and driven parts of the transmission system can be disassembled without axial displacement, making assembly, disassembly, and inspection convenient. At the same time, it is also necessary to pay attention to selecting appropriate assembly methods, such as dynamic pressing method, static pressing method, or temperature difference assembly method, to ensure the correct installation and stable operation of the coupling.

Elastic diaphragm couplings play an important role in various fields due to their unique structure and superior performance.

Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

URL: https://m.rokee.com/coupling-cases/elastic-diaphragm-coupling.html